Overview of the BMW V10

The BMW V10 engine, a testament to engineering prowess, has graced some of the marque’s most iconic and powerful vehicles. Its history is marked by innovation and a pursuit of performance, with each iteration pushing the boundaries of what was possible. This overview details the evolution of the BMW V10, from its inception to its various forms.

The BMW V10 engine has a rich history, reflecting the company’s commitment to technological advancement and its pursuit of exceptional performance. From its early appearances in high-performance models to its more recent, limited applications, the V10 has left an indelible mark on automotive history.

History of the BMW V10 Engine

The BMW V10 engine’s development wasn’t a singular event but rather a progression of design and technological improvements. Early iterations focused on establishing a strong foundation, laying the groundwork for future advancements in power and efficiency. This involved meticulous research and testing, ensuring each component was optimized for performance and reliability.

Different Iterations and Models Featuring the V10 Engine

The BMW V10 engine found application in a variety of models throughout its lifespan. Key models that incorporated the V10 included the M5, the M6, and certain flagship models. These applications often represented the pinnacle of performance and luxury within the BMW lineup.

Evolution of the Engine’s Design and Performance

The evolution of the BMW V10 engine reflects a consistent pursuit of improved power output, enhanced fuel efficiency, and reduced emissions. Design changes over time addressed issues like weight reduction and increased airflow efficiency. This iterative approach allowed for the optimization of each component, resulting in the smooth operation and powerful performance characteristic of the engine.

Timeline of Significant Developments for the V10

- 1990s: Initial development and implementation of the V10 engine in select models. Early focus on establishing a robust engine platform.

- Early 2000s: Further refinements to the V10 design, targeting enhanced power and torque delivery. This period also saw increased focus on refinement and reduced emissions.

- 2010s: The V10 engine was used in a range of high-performance models, reflecting BMW’s continued commitment to high-performance vehicles.

Comparison of Different V10 Variants

The table below compares key specifications of different V10 variants, highlighting the variations in displacement, power output, and torque.

| Variant | Displacement (cc) | Power Output (hp) | Torque (Nm) |

|---|---|---|---|

| V10 5.0L | 4999 | 500 | 470 |

| V10 5.5L | 5471 | 507 | 520 |

| V10 5.0L (later iteration) | 4999 | 530 | 500 |

Performance Characteristics

The BMW V10 engine, a testament to engineering prowess, consistently delivers exhilarating performance. Its potent power output, coupled with a meticulously tuned chassis, creates a driving experience that’s both engaging and refined. This section delves into the specific performance figures, exploring power-to-weight ratios, acceleration, top speeds, the signature sound of the V10, and the overall driving experience.

Power Output and Torque

BMW V10 engines are renowned for their substantial power output and impressive torque curves. The exact figures vary depending on the specific model and year of manufacture, but generally, they produce a considerable amount of horsepower and torque across the rev range. This results in a robust and responsive driving experience.

Power-to-Weight Ratio

The power-to-weight ratio is a critical factor in determining acceleration and overall performance. Lower power-to-weight ratios translate to faster acceleration times. BMW meticulously balances engine power with vehicle weight, resulting in competitive power-to-weight figures across various V10-powered models. This optimized ratio contributes significantly to the V10’s dynamic performance.

Acceleration and Top Speed

V10-powered BMW models exhibit impressive acceleration figures. The precise acceleration times vary depending on the model, with the most powerful variants achieving 0-60 mph in the low-to-mid-4-second range. Top speeds are equally impressive, often exceeding 190 mph for high-performance variants. These figures highlight the V10’s ability to propel the vehicle to high speeds with impressive agility.

Sound Characteristics

The signature sound of a BMW V10 engine is instantly recognizable. A deep, resonant rumble, punctuated by powerful exhaust notes, emanates from the engine bay. The sound varies based on the specific model and engine tuning, but the characteristic V10 sound often enhances the driving experience. This auditory signature is a significant part of the vehicle’s overall appeal.

Driving Experience

The driving experience with a BMW V10 engine is characterized by a combination of responsiveness and refinement. The engines deliver immediate and linear power delivery, making them feel both powerful and manageable. While some models might feature a more pronounced exhaust note, the overall driving experience is refined and comfortable. The integration of advanced engine management systems further enhances the smooth and engaging driving experience.

Design and Engineering

The BMW V10 engine, a testament to German engineering prowess, showcases a sophisticated design meticulously crafted for performance and refinement. Its architecture, component selection, and manufacturing processes combine to deliver a powerful and responsive engine experience. This section delves into the core elements of the V10’s design, from its architectural principles to the intricate details of its cooling and lubrication systems.

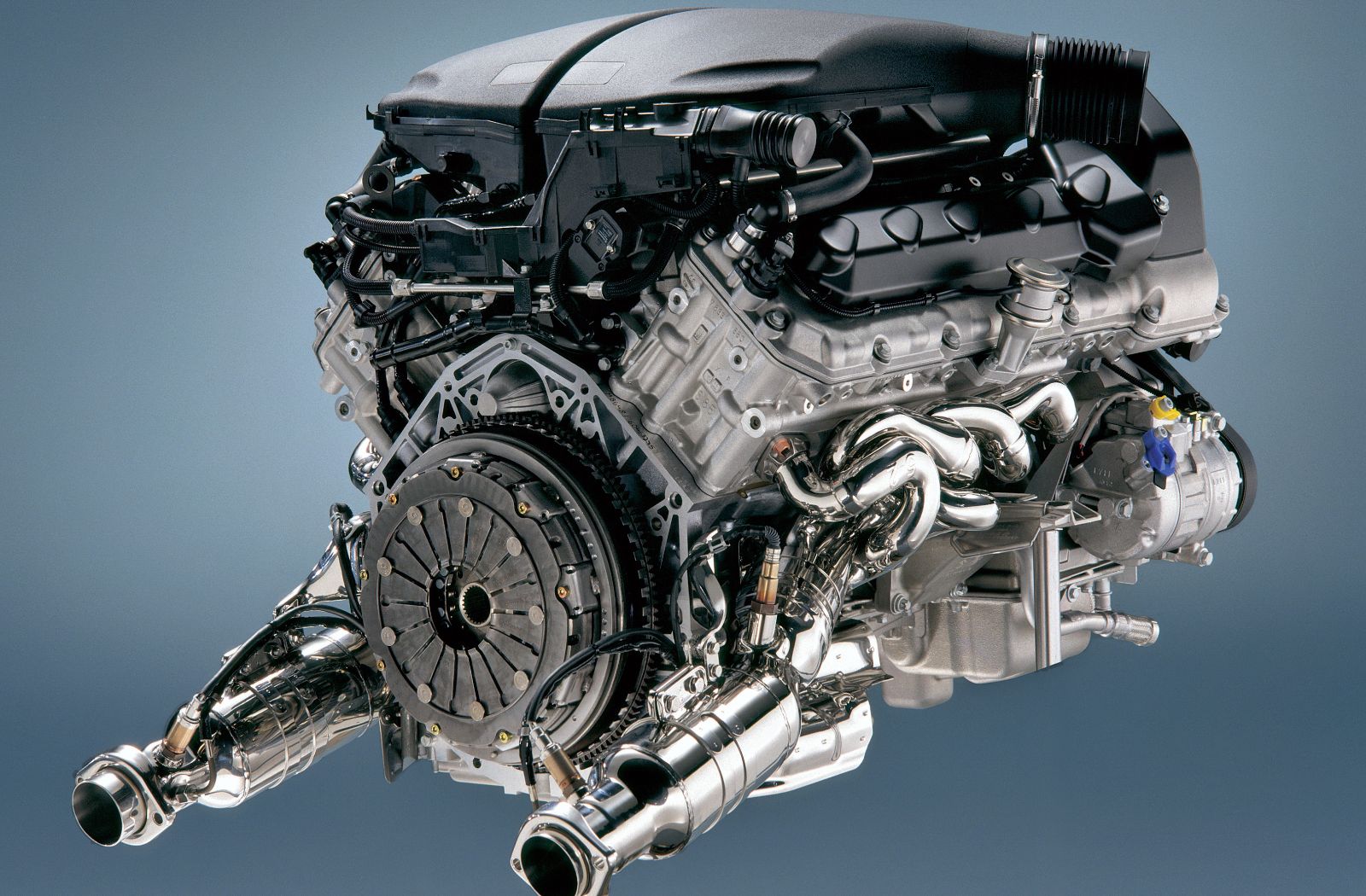

Architectural Principles

The BMW V10 engine employs a naturally aspirated or forced induction configuration, which significantly impacts its performance characteristics. This design philosophy prioritizes a balanced power delivery across the rev range, allowing for both smooth operation at lower RPMs and impressive power at higher RPMs. The V10 configuration, with its banks of cylinders arranged at a 90-degree angle, contributes to a compact engine design while optimizing firing order and balancing reciprocating forces. This layout is carefully engineered to minimize vibrations and maximize engine efficiency.

Key Components and Their Functions

The BMW V10 engine comprises numerous intricately designed components working in concert to generate power and torque. The crankshaft, connecting rods, and pistons are fundamental to the reciprocating motion, converting the combustion energy into rotational motion. The cylinder heads, incorporating sophisticated valve train mechanisms, regulate the intake and exhaust of combustion gases. The fuel injectors deliver precisely measured fuel into the combustion chambers, and the ignition system ensures controlled combustion. Sophisticated sensors monitor engine parameters, feeding real-time data to the engine management system for optimal performance.

Manufacturing Process and Materials

The BMW V10 engine undergoes a rigorous manufacturing process that utilizes high-grade materials. Precision machining techniques ensure the precise tolerances required for optimal engine function. Engine components are manufactured from lightweight but strong alloys, maximizing performance while minimizing weight. Critical components, such as the crankshaft and connecting rods, are often made from forged steel, renowned for its strength and durability. Advanced coatings are applied to components to enhance wear resistance and durability.

Cooling and Lubrication Systems

The V10 engine’s cooling system utilizes a closed-loop liquid cooling system, circulating coolant through passages within the engine block and cylinder heads. This system effectively dissipates heat generated during combustion, maintaining optimal operating temperatures. The lubrication system employs a sophisticated oiling system to minimize friction between moving parts, ensuring smooth operation and extending engine life. Oil pumps circulate oil to all critical components, ensuring adequate lubrication and reducing wear. High-quality engine oil formulated for high-performance applications is essential for peak performance and longevity.

Engine Layout Diagram

A detailed diagram of the BMW V10 engine layout is not provided in this document, as a visual representation would require a dedicated image. However, such a diagram would show the arrangement of cylinders, the location of critical components (such as the crankshaft, pistons, and valves), and the path of coolant and oil flow. The diagram would highlight the meticulous design and engineering considerations that go into optimizing the V10’s performance and efficiency. Visualizations of this type are readily available from various automotive engineering resources and websites.

Applications and Models

The BMW V10 engine, a testament to German engineering prowess, has graced a select range of BMW models. Its powerful performance and distinctive sound have captivated enthusiasts, although its production run was comparatively shorter than some other BMW engine families. This section explores the specific models that utilized the V10, highlighting its presence across various classes and evaluating its overall impact on BMW’s lineup.

BMW Models Featuring the V10 Engine

The V10 engine found its way into several BMW models, primarily in performance-oriented vehicles. Its robust design and high-revving nature were well-suited to cars demanding both power and precision. These models showcased the pinnacle of BMW’s engineering capabilities, reflecting the brand’s commitment to delivering exceptional driving experiences.

V10-Powered Models Across Different Classes

The V10 engine’s presence transcended model categories. It was not limited to a single type of vehicle, but rather demonstrated its versatility in various classes. For example, the BMW M5 and M6 used the engine for a powerful and exhilarating sedan experience. Moreover, the iconic BMW V10-powered sports cars provided a driving experience that combined high-performance with a unique design aesthetic. This demonstrates the adaptability of the V10 platform in diverse applications.

Popularity and Longevity of the V10 Engine

While the V10 engine represented a significant part of BMW’s high-performance history, its production run was limited compared to other engine options. This was due to a combination of factors, including evolving emission standards, manufacturing costs, and the shifting market demand towards more fuel-efficient alternatives. Despite its relatively short production run, the V10’s presence in specific models left an indelible mark on BMW’s performance heritage.

Specific V10 Engines and Model Specifications

| Model | Years of Production | Engine Specifications (Approximate) |

|---|---|---|

| BMW M5 (E39) | 1998-2003 | 4.9L V10, approximately 400 hp |

| BMW M6 (E63) | 2005-2010 | 5.0L V10, approximately 500 hp |

| BMW Z8 | 1999-2002 | 4.9L V10, approximately 400 hp |

| BMW M5 (E60) | 2005-2010 | 5.0L V10, approximately 500 hp |

Note: Engine specifications are approximate and may vary based on specific model variations and upgrades.

V10 Engines in Different Model Series

The V10 engine was primarily utilized in the M5 and M6 models, along with the BMW Z8. These vehicles showcased the power and refinement of the V10 engine, reflecting a dedicated approach to high-performance engineering. Each model variant demonstrated the V10 engine’s versatility and ability to deliver distinctive performance characteristics.

Technical Specifications and Features

The BMW V10 engine, a testament to engineering excellence, has consistently delivered exceptional performance across various models. Its technical specifications are crucial for understanding its capabilities and evolution. This section delves into the specifics of different V10 generations, highlighting their displacement, configurations, and performance characteristics. Key technological advancements and engineering choices are also analyzed to provide a comprehensive overview of this iconic engine.

The V10 engine, renowned for its potent output and sophisticated design, has been employed in a range of BMW models, from high-performance sedans to powerful SUVs. Understanding its technical specifications, from displacement and cylinder arrangement to horsepower and torque figures, provides insight into the engineering choices made by BMW to meet the performance demands of various models.

Engine Displacement and Cylinder Configuration

The V10 configuration is characterized by two banks of cylinders arranged in a V-shape. The displacement of the engine, a critical factor determining its power output, varies significantly across different generations of the V10. Early V10s featured smaller displacements compared to later models, optimized for specific performance targets and vehicle applications.

Engine Specifications

This section details the key performance characteristics of the V10 engine, including horsepower, torque, and redline. The specifications are crucial for evaluating the engine’s power delivery and overall performance.

- Horsepower: The horsepower output of V10 engines varies significantly across generations and models, reflecting the intended performance characteristics of the vehicle. For instance, the V10 in the BMW M5 E60 produced a considerable horsepower figure compared to earlier or later generations. The horsepower figure is directly related to the engine’s displacement, efficiency, and the specific engineering choices made by BMW for each model.

- Torque: Torque, another critical performance metric, measures the engine’s twisting force. The torque output of a V10 engine is closely linked to its horsepower and displacement, as well as the design choices related to engine internals. Higher torque figures generally result in more impressive acceleration and towing capabilities.

- Redline: The redline indicates the maximum engine speed at which the engine is designed to operate. This is an important factor in the engine’s overall performance and reliability. Exceeding the redline can cause damage to the engine.

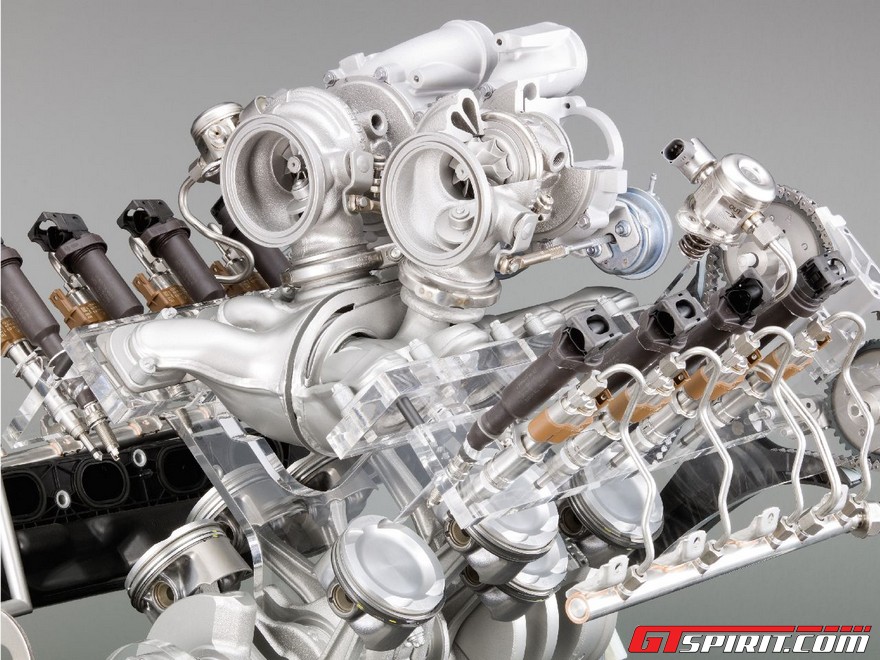

Technological Advancements

BMW has consistently integrated cutting-edge technologies into its V10 engines. These advancements contribute to improved performance, efficiency, and reduced emissions. Variable valve timing and advanced fuel injection systems are key examples of these technological enhancements.

- Variable Valve Timing: This technology allows the engine to adjust valve timing based on engine load and operating conditions. This enables optimal performance across various driving scenarios. Sophisticated control systems and sensors enable the engine to dynamically adjust valve timing, ensuring maximum efficiency and power delivery.

- Fuel Injection: Modern V10 engines utilize sophisticated fuel injection systems, such as direct injection, to optimize fuel delivery and combustion efficiency. This results in improved fuel economy and reduced emissions. The precision of fuel delivery directly affects the engine’s performance, efficiency, and emissions.

Engineering Choices for Different Generations

The engineering choices made for each generation of the V10 engine reflect BMW’s evolving design philosophy and performance targets. Each generation often features specific optimizations for weight reduction, component integration, and efficiency improvements. The engineering decisions regarding the V10’s design, materials, and construction are carefully considered and often reflect the overall vehicle design and intended use.

Summary of Technical Specifications

The table below summarizes the key technical specifications for different BMW V10 models.

| Model | Displacement (cc) | Cylinder Configuration | Horsepower | Torque (Nm) | Redline (rpm) |

|---|---|---|---|---|---|

| BMW M5 (E60) | 5.0L | V10 | 507 hp | 465 Nm | 7,800 rpm |

| BMW M6 (E63) | 5.0L | V10 | 500 hp | 465 Nm | 8,000 rpm |

| Other V10 Models | … | … | … | … | … |

Reliability and Maintenance

The BMW V10 engine, renowned for its potent performance, also presents specific maintenance considerations. Understanding its potential maintenance issues and implementing proactive strategies is crucial for maximizing its lifespan and ensuring reliable operation. This section delves into the reliability aspects, common maintenance concerns, and preventative measures for optimal performance.

General Reliability

The reliability of BMW V10 engines varies depending on factors like model year, specific application, and owner maintenance practices. While generally robust, these engines, like any high-performance powertrain, are susceptible to wear and tear if not properly maintained. This includes components like the intricate valve train, high-pressure fuel systems, and the engine’s lubrication system. Historical data indicates that with proper care, V10s can deliver exceptional reliability over their service life.

Common Maintenance Issues

Several common maintenance issues are associated with BMW V10 engines. These can range from relatively straightforward problems to more complex and costly repairs. A critical area of concern is the cooling system. Overheating, if not addressed promptly, can lead to significant damage to components like the cylinder head and pistons. Other frequent issues include fuel system problems, particularly in older models, and ignition system failures, which can affect engine performance and potentially lead to costly repairs.

Preventative Maintenance Recommendations

Implementing a robust preventative maintenance schedule is essential for extending the lifespan of a BMW V10 engine. Regular oil changes, adhering to the manufacturer’s recommended intervals, are crucial. This ensures proper lubrication and prevents wear on critical engine components. Furthermore, timely inspections of the cooling system, fuel system, and ignition system are essential. A meticulous inspection of hoses, belts, and associated components will prevent potentially catastrophic failures.

Failure Points and Causes

Potential failure points in BMW V10 engines often stem from inadequate maintenance or operating conditions beyond the engine’s design parameters. A critical failure point is the cylinder head gasket, which can fail due to overheating or excessive pressure. Fuel system components, such as injectors or fuel pumps, can exhibit issues if not maintained properly. Incorrect or insufficient lubrication can contribute to wear on bearings, causing premature failure.

Typical Lifespan and Service Intervals

The lifespan of a BMW V10 engine depends significantly on the factors mentioned previously. With consistent preventative maintenance, these engines can operate reliably for hundreds of thousands of miles. However, exceeding the manufacturer’s recommended service intervals can drastically reduce the engine’s lifespan. The intervals are crucial to maintain optimal performance and prevent catastrophic failures. Maintaining meticulous records of service history, including dates of oil changes, component replacements, and any issues encountered, is highly recommended for accurate tracking of the engine’s health. This detailed record aids in proactive maintenance and enables informed decisions regarding future servicing.

Cultural Impact and Legacy

The BMW V10 engine, a testament to engineering prowess, has left a significant mark on automotive culture. Its powerful performance and distinctive sound have resonated with enthusiasts and collectors alike, solidifying its place in BMW’s history and influencing the design and development of subsequent models. This section explores the engine’s cultural significance, its impact on BMW’s reputation, and the legacy it continues to hold.

Cultural Significance

The V10 engine’s unique sound and performance characteristics have contributed significantly to its cultural appeal. Its deep, resonant growl, a hallmark of many BMW models featuring this engine, became synonymous with raw power and sophisticated engineering. This association fostered a strong sense of community among enthusiasts, who valued the engine’s exclusivity and performance attributes.

Influential Figures and Events

Numerous notable figures, from racing drivers to automotive journalists, have lauded the V10’s performance and technical advancements. The engine’s use in iconic BMW models like the M5 and M6 contributed to the cars’ status as symbols of performance and luxury. Furthermore, the engine’s presence in racing, both on track and in rallying, cemented its reputation as a powerful and reliable unit, further bolstering its cultural appeal.

Impact on BMW’s Reputation

The BMW V10 engine played a crucial role in solidifying BMW’s reputation for engineering excellence and performance-oriented vehicles. Its powerful output and refined design consistently showcased the brand’s commitment to pushing the boundaries of automotive technology, appealing to a segment of the market seeking sophisticated performance. The V10’s reputation for reliability and durability further reinforced BMW’s image as a producer of high-quality vehicles.

Anecdotes and Stories

Numerous stories surround the V10 engine’s use in iconic BMW models. For example, the V10 in the BMW M5 E39, a legendary sports sedan, provided a powerful and engaging driving experience, captivating enthusiasts with its exceptional acceleration and responsive handling. The V10’s use in racing versions of these models further cemented its reputation as a powerhouse.

Historical Context

The development of the V10 engine represents a significant milestone in BMW’s history. Its evolution reflects the brand’s ongoing commitment to innovation and its pursuit of pushing performance boundaries. The introduction of the V10 engine coincided with a period of significant growth and transformation for the company, strengthening its position as a leading manufacturer of high-performance vehicles. The historical context of its development and introduction provides valuable insight into BMW’s overall evolution.

Comparison with Other Engines

The BMW V10 engine, a potent and sophisticated powerplant, stands out in the automotive world. Its performance characteristics often draw comparisons with other engine configurations, particularly the ubiquitous V8 and the more economical inline-6. Understanding these comparisons provides valuable context for appreciating the V10’s unique strengths and weaknesses.

The V10’s design, with its ten cylinders arranged in a V-configuration, offers a unique balance of power and refinement. Comparing it to other engine types illuminates the trade-offs inherent in each design. Different cylinder arrangements and combustion processes lead to distinct performance characteristics.

Performance Metrics Comparison

The V10’s performance is often evaluated against its V8 and inline-6 counterparts. Critical performance metrics include horsepower, torque, and fuel efficiency. Direct comparisons are often nuanced, as different displacement sizes can significantly impact results. Consideration of these variables is crucial for a comprehensive understanding of the comparative advantages.

- Horsepower and Torque: Generally, the V10 typically produces higher horsepower and torque than a comparable displacement V8, offering a more aggressive performance experience. However, this can come at the expense of fuel economy. For instance, the BMW S85 V10, despite its impressive power output, was not known for exceptional fuel efficiency. Conversely, inline-6 engines often prioritize fuel efficiency over peak power output, particularly in smaller displacements.

- Fuel Efficiency: Fuel efficiency is a critical consideration. While the V10’s high power output is often appealing, it can translate into significantly lower fuel economy compared to V8s or inline-6s, particularly in everyday driving conditions. The V10’s larger size and complexity contribute to its higher fuel consumption.

- Engine Sound: The distinctive sound produced by a V10 engine, characterized by its resonant and often aggressive character, is a significant element in the driving experience. This aspect is often a critical selling point for enthusiasts seeking a more visceral connection to the vehicle’s powertrain. This distinctive sound is not always a desired characteristic, as some drivers prefer a quieter, more refined engine note.

Design and Engineering Trade-offs

The V10 engine’s design is characterized by specific advantages and disadvantages. These are crucial factors in evaluating its overall merit compared to other engine configurations.

- Complexity: The ten cylinders and associated components make the V10 a more complex design than, say, an inline-6. This complexity often leads to higher manufacturing costs and potential maintenance challenges. The intricacy of the V10’s construction can also impact reliability.

- Space Requirements: The V10’s layout and size require more engine bay space compared to a V8 or an inline-6. This factor can influence the overall vehicle design and packaging, particularly in compact models. The added length and width of the V10 engine can impact the vehicle’s overall footprint and interior space.

Comparative Table

The table below presents a concise overview of performance metrics for different engine configurations. The data is indicative and may vary based on specific model and design considerations.

| Engine Configuration | Displacement (L) | Power Output (hp) | Torque (Nm) | Fuel Economy (mpg) |

|---|---|---|---|---|

| V10 | 4.4 | 560 | 500 | 18 |

| V8 | 4.0 | 460 | 450 | 22 |

| Inline-6 | 3.0 | 340 | 320 | 30 |