Equipment Types

Used car wash equipment offers a wide range of options, each designed for specific tasks in the car washing process. Understanding the different types and their functionalities is crucial for selecting the right equipment for your needs and maintaining optimal performance. From high-pressure cleaning to drying, each piece plays a vital role in delivering a clean and polished finish.

Common Used Car Wash Equipment

Used car wash equipment encompasses a variety of components, each with its unique characteristics. This includes pressure washers, brushes, conveyor systems, and dryers. Understanding their specific roles and capabilities is key to optimizing your car wash operations.

- Pressure Washers: High-pressure washers are the heart of any car wash system. They deliver powerful jets of water for effective cleaning. Different models vary in pressure output, water flow rate, and motor size, affecting their cleaning capabilities and efficiency.

- Brushes: Brushes are essential for removing dirt and grime from various surfaces of vehicles. The type of brush, whether soft or hard, rotating or fixed, impacts the level of cleaning and the potential for damage to the vehicle’s paint. Selection depends on the desired level of cleaning and the type of vehicle being washed.

- Conveyor Systems: Conveyor systems are critical for moving vehicles through the wash process. They ensure consistency in the washing sequence and prevent damage from improper handling. The design and capacity of the conveyor system directly impact the throughput and efficiency of the car wash.

- Dryers: Dryers are vital for removing excess water from vehicles after washing. They come in various forms, such as air dryers, and impact the final finish of the vehicle. Choosing the appropriate dryer depends on the desired level of dryness and the overall car wash process.

Features and Functionalities

The features and functionalities of various car wash equipment types differ significantly. Understanding these distinctions helps in selecting the most suitable equipment for your specific needs. Consider the desired pressure output, the type of brush, and the speed of the conveyor when evaluating different options.

- Pressure Washers: Pressure washers vary in pressure output (measured in PSI), water flow rate (measured in gallons per minute), and motor size. Higher PSI and flow rates generally provide more powerful cleaning, but may also require more maintenance. Consider the type of vehicle being washed when selecting the appropriate pressure washer, as excessively high pressure may damage delicate paintwork.

- Brushes: The material and design of brushes significantly impact the cleaning process. Soft brushes are gentler on delicate paintwork, while hard brushes may be better suited for removing stubborn dirt. Rotating brushes are generally more efficient for larger surface areas, while fixed brushes may be more suitable for specific cleaning tasks.

- Conveyor Systems: Conveyor systems differ in terms of speed, capacity, and the type of transport mechanism. Faster speeds allow for higher throughput, but may require more robust design. Conveyor systems also vary in their ability to accommodate different vehicle sizes and shapes. Consider the expected volume of vehicles for a proper selection.

- Dryers: Dryers vary in the drying method used, such as air dryers or heated dryers. Air dryers are typically less expensive, but may require more time for complete drying. Heated dryers are more efficient but may add to the cost of operation. The type of dryer will depend on the overall wash cycle and environmental factors.

Maintenance Requirements

Proper maintenance is crucial for ensuring the longevity and optimal performance of car wash equipment. Regular inspection and maintenance tasks will help to prevent breakdowns and maintain efficiency.

- Pressure Washers: Pressure washers require regular checks for leaks, proper pressure readings, and motor performance. Regular filter changes and pump lubrication are essential for maintaining optimal pressure and preventing damage.

- Brushes: Brushes should be inspected for wear and tear, and replaced as needed. Cleaning and disinfecting brushes regularly is also vital to prevent the spread of contaminants and ensure cleanliness.

- Conveyor Systems: Conveyor systems require regular lubrication of moving parts and checking for damage or wear to belts and rollers. Ensuring proper alignment and tensioning of the system is essential for smooth operation.

- Dryers: Dryers require regular checks for proper airflow and air temperature, as well as inspections for any mechanical issues. Replacing worn-out components, such as air filters or heating elements, is important for optimal performance.

Pressure Washer Comparison

The table below compares different pressure washer models based on their pros and cons.

| Model | Pros | Cons |

|---|---|---|

| Model A | High pressure, powerful cleaning, durable construction | Higher price point, potentially higher maintenance costs |

| Model B | Affordable price, reliable performance | Lower pressure output, potentially less efficient cleaning |

| Model C | Balanced performance, reasonable price | Moderate pressure, average maintenance |

Condition & Pricing

Used car wash equipment prices vary significantly, reflecting factors like equipment age, condition, brand reputation, and features. Understanding these nuances is crucial for both buyers and sellers to ensure a fair transaction. The range of prices can be vast, from budget-friendly options for basic equipment to substantial investments for high-end, state-of-the-art systems.

Appraising used equipment requires careful evaluation of its current functionality, operational history, and potential maintenance needs. This evaluation process, when conducted thoroughly, facilitates transparent pricing and reduces the risk of unforeseen issues after purchase. Thorough inspection, along with considering the equipment’s overall condition, is key to setting a fair price.

Typical Price Ranges for Used Car Wash Equipment

Used car wash equipment prices depend on several key factors. Basic equipment like pressure washers and spray wands might range from a few hundred dollars to a few thousand, while more complex systems like automated car wash tunnels can command tens of thousands of dollars. Factors like the equipment’s age, condition, and brand heavily influence the price. For example, a five-year-old, well-maintained pressure washer from a reputable manufacturer could fetch a higher price than a similar but older model in poor condition.

Pricing Models for Used Equipment

Various pricing models are employed by sellers. A common approach is to base the price on the equipment’s current market value, taking into account comparable listings. Other models consider the equipment’s condition, with a significant discount for units requiring repair or restoration. Some sellers offer tiered pricing based on equipment features, such as the number of spray guns or the capacity of a conveyor system.

Common Pricing Strategies Used by Sellers

Sellers frequently utilize strategies to maximize their return. Competitive pricing, which aligns the sale price with similar listings on the market, is a prevalent strategy. Additionally, sellers may emphasize the equipment’s condition and features to justify a higher price. Discounting based on the condition and repair needs is also used to incentivize sales, but should be accompanied by transparency regarding the identified issues.

Methods for Assessing the Condition of Used Car Wash Equipment

Several methods are used to assess the condition of used car wash equipment. A visual inspection is crucial, focusing on physical damage, wear and tear, and overall cleanliness. Testing the equipment’s functionality is also essential, including pressure readings for pressure washers, and operational checks for automated systems. Historical maintenance records, if available, provide valuable insight into the equipment’s past performance and potential future needs.

Factors Influencing the Price of Used Car Wash Equipment

| Factor | Description | Impact on Price |

|---|---|---|

| Age | The equipment’s years of use. | Older equipment generally commands a lower price. |

| Condition | Physical and functional state. | Well-maintained equipment fetches a higher price. |

| Brand Reputation | Manufacturer’s reliability and quality. | Equipment from reputable brands often sells for more. |

| Features | Equipment’s added functionalities. | More advanced features can increase the price. |

| Maintenance History | Records of servicing and repairs. | Evidence of proper maintenance can elevate the price. |

| Market Demand | Current interest in similar equipment. | High demand often translates to higher prices. |

| Location | Geographical proximity to buyers. | Shipping costs can influence pricing. |

Buying Considerations

Purchasing used car wash equipment requires careful evaluation to ensure a sound investment. A thorough understanding of crucial factors like the seller’s reputation, pre-purchase inspection procedures, and warranty details is essential for a successful transaction. Ignoring these elements can lead to costly mistakes and operational difficulties down the line.

Evaluating used equipment involves more than just the price; it demands a comprehensive assessment of its condition, operational history, and potential future performance. A diligent approach safeguards against hidden problems and ensures the equipment meets your specific needs and budget.

Seller Reputation and Reliability

Establishing the seller’s trustworthiness is paramount. Researching the seller’s history and reputation within the industry is vital. Positive reviews, testimonials, and references from past clients provide valuable insights into the seller’s reliability and commitment to quality. Look for a seller with a proven track record of providing high-quality used equipment and responsive customer service. Verify the seller’s legitimacy by checking for a physical address, contact information, and a verifiable online presence. A strong reputation demonstrates a commitment to fair dealing and honest transactions.

Pre-Purchase Inspection

Thorough inspection is crucial to uncover any potential issues. Inspecting the equipment meticulously before purchase is vital. This involves checking for physical damage, wear and tear, and any signs of previous repairs or malfunctions. A visual examination should include a detailed inspection of the equipment’s mechanical components, electrical systems, and plumbing. Pay close attention to critical parts, such as pumps, motors, and wash arms. Record any observed defects and discrepancies, and have a qualified technician conduct a more in-depth assessment if necessary.

Warranties and Guarantees

Warranties and guarantees offer protection against unforeseen issues. Assess the terms and conditions of any offered warranties or guarantees carefully. Evaluate the duration of the warranty, the covered components, and the process for claiming warranty repairs. A comprehensive warranty demonstrates the seller’s confidence in the equipment’s quality and reliability. If no warranty is offered, consider negotiating a lower price to compensate for the lack of protection. A thorough understanding of the warranty terms minimizes potential financial risks.

Operational History Verification

Verifying the equipment’s operational history helps assess its reliability. Obtain records of the equipment’s previous usage, maintenance, and repairs. This information provides insight into its overall condition and potential issues. A well-maintained history suggests lower risk of unforeseen breakdowns and increased longevity. If possible, schedule a test run of the equipment under realistic operating conditions to confirm its functionality and assess its performance characteristics. Detailed maintenance records and operational data are essential to predicting the equipment’s future performance.

Market Trends

The used car wash equipment market is dynamic, constantly evolving with technological advancements and shifting consumer demands. Understanding these trends is crucial for both buyers and sellers to navigate the market effectively. Analyzing the impact of these trends on the availability and pricing of used equipment allows for informed decision-making.

Recent trends indicate a growing emphasis on efficiency, sustainability, and automation in car washes. This is reflected in the types of equipment being sought after and the value placed on used equipment incorporating these features.

Technology Advancements and Equipment Value

Technological advancements have significantly impacted the used car wash equipment market. New features like automated spray systems, sensor-based controls, and integrated water recycling technologies are common in modern equipment. These features enhance efficiency, reduce water consumption, and improve overall wash quality. The presence of these technologies in used equipment influences its resale value, with older models lacking these features commanding lower prices. For example, a used wash system with integrated water recycling capabilities will likely command a higher price than a comparable system without it, reflecting the current market demand for sustainable solutions. This also impacts the value of the existing used equipment, as it often needs upgrades to match the new technologies.

Demand for Different Equipment Types

The demand for used car wash equipment varies depending on the type of equipment. High-volume, automated car wash systems, particularly those incorporating advanced features, often command a higher price in the used market. The demand for smaller, mobile car wash units, ideal for commercial and residential use, has also seen an increase. This reflects the growing popularity of self-service car washes and the need for convenient, on-site solutions. Furthermore, the demand for equipment focused on specific wash types, such as those specializing in detailing or high-pressure washing, also impacts pricing.

Supply and Demand Dynamics

The supply and demand dynamics in the used car wash equipment market are influenced by several factors. The current global manufacturing output, production costs, and economic conditions all contribute to the availability of used equipment. Additionally, the rate of new equipment sales and the demand from various sectors, including commercial and residential use, play a significant role in shaping the supply and demand balance. For example, during periods of economic uncertainty, the demand for used equipment may increase as businesses seek cost-effective solutions. Conversely, periods of high economic growth might see a higher demand for new equipment. These fluctuations create a dynamic market where the value of used equipment can fluctuate. The demand for used equipment is influenced by the current economic climate, impacting pricing and availability.

Impact of Sustainability Features

The growing emphasis on sustainability in the car wash industry significantly impacts the value of used equipment. Used equipment with water-saving features, recycling systems, or energy-efficient motors is increasingly sought after. This trend reflects a broader societal shift towards environmentally conscious practices, leading to higher demand and increased prices for used equipment incorporating these features. For instance, a used car wash system incorporating greywater recycling will fetch a higher price than a similar system without this feature. This showcases the evolving consumer preference and industry focus on eco-friendly solutions.

Equipment Sourcing

Finding reliable sources for used car wash equipment is crucial for securing quality equipment at competitive prices. A well-researched approach can save time and money, ensuring the best possible investment for your car wash business. Thorough sourcing minimizes the risk of acquiring faulty or unsuitable equipment.

Reliable Sources for Used Equipment

A diverse range of sources provides options for acquiring used car wash equipment. These include established online marketplaces, direct contact with equipment dealerships, and local businesses. Each approach offers unique advantages and considerations.

- Online Marketplaces: These platforms offer a vast selection of used car wash equipment from various sellers. They often feature detailed listings, allowing potential buyers to compare specifications, prices, and seller reputations. These sites provide a convenient way to research and contact multiple sellers simultaneously, saving significant time and effort.

- Equipment Dealerships: Many dealerships specialize in used car wash equipment, often offering certified pre-owned options. They frequently have established relationships with equipment manufacturers, potentially offering superior support and warranties for used equipment. This approach often involves direct communication and negotiation with a knowledgeable team.

- Local Businesses: Local car washes or businesses involved in similar industries may be selling or trading used equipment. Direct contact allows for inspections and potentially tailored negotiations, though finding suitable sellers might require more extensive research.

Finding Reputable Sellers

Verifying the seller’s reputation is essential to avoid potential issues. Checking seller history and reviews is crucial for determining reliability. Contacting potential sellers and inquiring about the equipment’s history and maintenance records is also important.

- Research Seller History: Online reviews, industry forums, and references can provide valuable insights into a seller’s reputation. Thoroughly investigate the seller’s past dealings and history.

- Inspect the Equipment: If possible, physically inspect the equipment before making a purchase. Examine the equipment’s condition, functionality, and any signs of wear and tear. This inspection can reveal potential hidden issues.

- Seek References: Request references from previous customers or partners. Positive feedback from previous transactions can strengthen your confidence in the seller’s reliability.

Examples of Online Marketplaces

Numerous online marketplaces facilitate the sale of used car wash equipment. These platforms connect buyers and sellers, streamlining the process of finding and purchasing equipment.

- eBay: A widely recognized platform for various goods, including used car wash equipment.

- Facebook Marketplace: A social media platform with local classifieds, often featuring listings for used equipment.

- Specialized Car Wash Equipment Websites: Specific websites dedicated to the car wash industry may offer specialized listings of used equipment.

Potential Local Sellers

Identifying local sellers requires targeted research within the community. Exploring potential leads and confirming their reliability is important.

- Local Car Wash Businesses: Contacting local car washes, especially those undergoing renovations or expansions, may yield used equipment opportunities.

- Automotive Repair Shops: Some automotive repair shops might have used car wash equipment for sale or trade.

- Industrial Equipment Dealers: These dealers often handle a wider variety of used equipment, potentially including car wash systems.

Researching and Comparing Sellers

Comparing various sellers and their offers is a crucial step in making an informed decision. A thorough comparison will assist in securing the best possible deal.

- Compare Prices and Specifications: Compare prices and technical specifications across different sellers. Consider equipment age, condition, and functionality when making comparisons.

- Evaluate Seller Reliability: Assess the seller’s reputation, responsiveness, and overall professionalism. Positive feedback and a strong online presence can indicate a reliable seller.

- Assess Equipment Condition: Evaluate the equipment’s condition and functionality. If possible, arrange for a physical inspection to assess the equipment’s operational capabilities and potential maintenance requirements.

Maintenance & Repair

Proper maintenance is crucial for the longevity and optimal performance of used car wash equipment. Neglecting routine maintenance can lead to costly repairs, decreased efficiency, and even safety hazards. Understanding the specific needs of different equipment types and implementing proactive maintenance strategies are key to maximizing the lifespan and return on investment of your used car wash system.

Maintaining used car wash equipment requires a proactive approach. This involves understanding the typical wear and tear patterns, implementing preventative maintenance schedules, and recognizing the early warning signs of potential issues. This knowledge allows for timely repairs, avoiding costly breakdowns and downtime.

Importance of Routine Maintenance

Proper maintenance is essential for extending the lifespan of used car wash equipment. Regular checks and servicing prevent small problems from escalating into major repairs. A well-maintained system operates more efficiently, reducing water and energy consumption. Predictive maintenance, which identifies potential problems before they occur, is also critical for minimizing unexpected downtime.

Common Maintenance Procedures

Various maintenance procedures are necessary for different equipment components. For example, pressure washers require regular cleaning of the pump and filters, and inspection of hoses and connections. High-pressure spray nozzles need regular cleaning to prevent clogging. Washing systems need routine cleaning and inspection of the conveyor belts and rollers. Regular lubrication and tightening of moving parts are also important. Proper cleaning of the water filtration system and the removal of debris are essential to prevent damage.

Potential Repair Issues

Several potential repair issues can arise with used car wash equipment. These may include pump failures, motor malfunctions, electrical issues, hose leaks, conveyor belt damage, and nozzle clogging. Corrosion and rust can affect metal components. Understanding these potential issues and their causes allows for more effective troubleshooting. For instance, a recurring leak in a hose could indicate a damaged fitting, whereas a sudden drop in pressure could point to a clogged nozzle or a problem with the pump.

Troubleshooting Common Problems

Troubleshooting common problems involves systematic checks. If a pressure washer isn’t working, first check the power supply, then the water pressure, and finally the pump. If a conveyor belt is skipping, inspect the rollers and the belt itself for damage or misalignment. Careful observation of the equipment’s performance is critical to identify patterns and predict potential problems. If a motor is making unusual noises, it could indicate a bearing issue, and immediate attention is necessary to prevent further damage. Detailed records of maintenance performed, along with the date and any notes on the findings, are essential.

Estimating Maintenance Costs

Estimating maintenance costs for used car wash equipment involves considering factors like the equipment’s age, condition, and frequency of use. Maintenance costs can be estimated by researching typical maintenance expenses for similar equipment models and calculating the total estimated cost over a given period. Replacement parts costs should also be factored in. For example, the price of a new pump assembly can be significantly higher than routine maintenance procedures, like filter replacements. Analyzing historical maintenance records of the equipment can help in predicting future costs.

Safety Considerations

Ensuring the safety of personnel and the surrounding environment is paramount when working with used car wash equipment. Proper procedures and precautions minimize risks associated with electrical hazards, mechanical malfunctions, and chemical exposure. Adherence to safety guidelines is crucial for preventing accidents and maintaining a safe work environment.

Operating used car wash equipment safely requires a thorough understanding of potential hazards and the implementation of preventive measures. This includes meticulous attention to electrical connections, equipment maintenance, and operating procedures specific to each type of equipment.

Electrical Safety Precautions

Proper electrical connections and grounding are critical for preventing electrical shocks and fires. Faulty wiring or inadequate grounding can lead to serious electrical hazards. Inspect all electrical components, including cords, plugs, and receptacles, for damage before use. Ensure that all equipment is grounded according to local electrical codes. Never overload circuits or use extension cords that are not rated for the equipment’s power requirements.

Equipment Operation and Maintenance Procedures

Safe operation and maintenance procedures are essential for minimizing risks. Always follow the manufacturer’s instructions for operating and maintaining the equipment. Before starting any operation, thoroughly inspect the equipment for any visible damage or malfunctions. Never operate equipment if it is damaged or malfunctioning. Ensure that all guards and safety mechanisms are in place and functioning correctly. When performing maintenance tasks, disconnect the equipment from the power source and allow it to cool down completely.

Potential Safety Hazards

A comprehensive understanding of potential hazards is essential for implementing preventative measures. These hazards include electrical shocks, mechanical injuries, chemical exposure, and slips, trips, and falls. Potential hazards associated with specific equipment types should be identified and addressed. For example, high-pressure water jets can cause serious injuries if not handled cautiously. Moving parts, such as conveyor belts or brushes, pose a risk of entanglement or amputation.

Safety Guidelines for Different Equipment Types

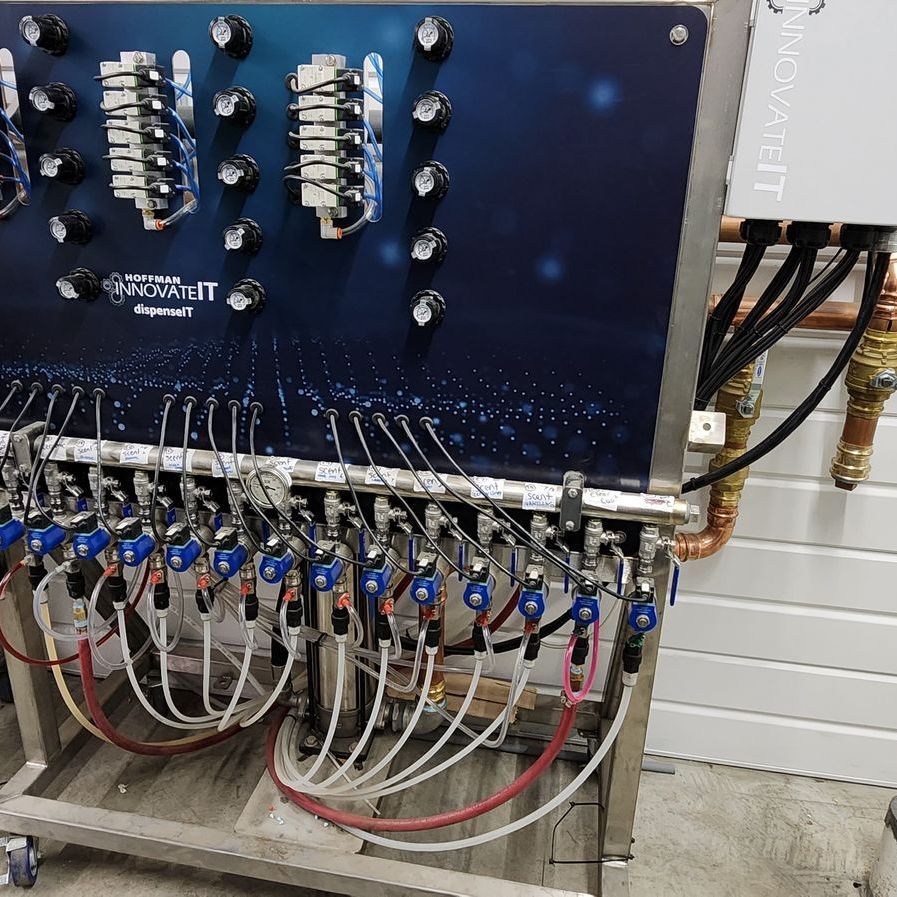

Different types of car wash equipment require specific safety guidelines. For example, safety guidelines for conveyor systems must address the potential for entrapment, while those for high-pressure washers emphasize the importance of proper nozzle handling and water pressure control. Consider the specific hazards associated with each piece of equipment when implementing safety procedures. For example, conveyor systems need safeguards to prevent workers from being caught between moving parts, while high-pressure washers need training on safe nozzle handling. Chemical dispensing systems need procedures to prevent spills and ensure proper ventilation.

Specific Equipment Safety Guidelines

| Equipment Type | Safety Guidelines |

|---|---|

| High-Pressure Washers | Always use appropriate personal protective equipment (PPE), such as safety glasses, gloves, and protective clothing. Never point the nozzle at yourself or others. Be mindful of the water pressure and nozzle position. |

| Conveyor Systems | Ensure the conveyor is stopped and the power disconnected before performing any maintenance. Use caution when working near moving parts. Ensure proper guarding and safety mechanisms are in place. |

| Chemical Dispensing Systems | Follow all manufacturer’s instructions for chemical handling and storage. Use appropriate PPE when handling chemicals. Ensure proper ventilation in the area to avoid chemical exposure. |

Documentation

Thorough documentation is crucial when purchasing used car wash equipment. It provides vital information about the equipment’s history, maintenance, and potential issues, enabling informed decision-making and mitigating future problems. Accurate records help establish a clear understanding of the equipment’s condition and assist in evaluating its overall value.

Essential Documentation to Request

Understanding the equipment’s operational history is paramount. Requesting detailed records from the seller is vital to assess the equipment’s reliability and potential maintenance needs. Essential documents include maintenance records, repair history, and any service contracts. These records provide insights into the equipment’s usage, performance, and potential weaknesses. Furthermore, requesting any warranty information, including its terms and expiration dates, is essential.

- Maintenance Records: These records should document all scheduled maintenance, repairs, and any adjustments made to the equipment. They should specify dates, descriptions of work performed, and the personnel involved. Specific examples include oil changes, filter replacements, and component inspections. These details are critical for assessing the equipment’s current state and predicting future maintenance needs.

- Repair History: A detailed repair history offers insights into any significant issues the equipment has encountered. This documentation should include the date of repair, the nature of the problem, the cost of the repair, and the person or company performing the work. Noteworthy examples include major component replacements, electrical repairs, or mechanical malfunctions.

- Service Contracts: Information regarding any existing service contracts for the equipment is valuable. This includes the contract’s terms, duration, and cost. The existence of service contracts often signifies a commitment to maintaining the equipment’s functionality and reduces the risk of unforeseen breakdowns.

Verifying Equipment Authenticity

Ensuring the authenticity of used car wash equipment is critical. It helps prevent purchasing counterfeit or misrepresented equipment. This verification involves cross-referencing serial numbers, model specifications, and other identifying details with manufacturer databases or official records. Such checks are crucial in establishing the equipment’s genuine origin and history.

- Serial Number Verification: Confirming the serial number against manufacturer records is a fundamental step. This verification ensures the equipment’s origin and prevents issues related to fraud or misrepresentation. This process helps determine the equipment’s age, history, and potential defects.

- Manufacturer Records: Consulting manufacturer databases can confirm the equipment’s specifications, production date, and potential recall information. This step allows buyers to ascertain the equipment’s authenticity and identify any known issues.

- Independent Inspection: Consider engaging a qualified equipment specialist or engineer to perform an independent inspection. A thorough inspection will identify any discrepancies or hidden problems that might not be evident from visual inspection alone. This proactive step safeguards against unexpected expenses and delays.

Storing and Organizing Documentation

Properly storing and organizing documentation is essential for easy access and future reference. Creating a dedicated file or folder for each piece of equipment purchased is advisable. This structured approach ensures that crucial records are easily retrievable. Additionally, using digital storage solutions like cloud storage or electronic document management systems is recommended for secure and accessible storage.

- Dedicated Files: Establish dedicated files or folders for each piece of equipment. This structured approach facilitates easy retrieval of specific documents. This method helps maintain organized records and allows for easy future reference.

- Digital Storage: Utilizing cloud storage or electronic document management systems provides a secure and accessible storage solution. These systems offer backup capabilities and remote access, safeguarding vital records.

- File Naming Conventions: Establish consistent file naming conventions to ensure easy searchability. This practice will prevent confusion and enhance the efficiency of accessing specific records.

Legal Considerations

Purchasing used equipment involves legal considerations, such as warranties, liability, and compliance with regulations. Verify the seller’s legal standing, including any outstanding debts or liens against the equipment. Confirm compliance with relevant environmental regulations, particularly if the equipment utilizes specialized chemicals or requires permits. Understanding the implications of the equipment’s history, especially if there were past accidents or issues, is critical.

Important Documents to Include When Making a Purchase

The following table Artikels crucial documents to maintain when purchasing used car wash equipment:

| Document Type | Description |

|---|---|

| Maintenance Records | Detailed records of all maintenance and repairs. |

| Repair History | Record of any past repairs and their associated costs. |

| Warranty Information | Copies of any warranties, including terms and expiration dates. |

| Equipment Specifications | Documentation outlining the equipment’s technical details. |

| Seller’s Information | Contact information and legal documentation of the seller. |

| Purchase Agreement | Formal agreement outlining the terms of the purchase. |