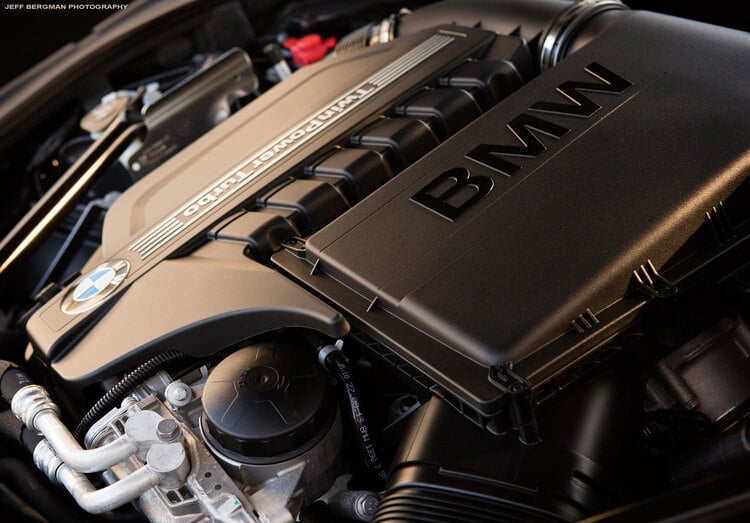

Overview of the N55 Engine

The BMW N55 engine, a twin-turbocharged inline-6, revolutionized the performance landscape for the brand. Its introduction marked a significant departure from previous naturally aspirated engines, delivering a potent blend of power and efficiency. This engine architecture, characterized by its sophisticated design and advanced features, quickly gained a strong reputation for its performance characteristics and impressive engineering.

The N55’s design incorporated numerous innovations aimed at achieving both high output and reduced emissions. This involved meticulous optimization of the combustion process and the integration of advanced turbocharging systems. The result was a powerful and efficient engine that resonated with performance-oriented drivers while also meeting evolving environmental standards.

Design Features and Components

The N55’s design is a testament to BMW’s commitment to engineering excellence. Key features include a double-vaned variable intake manifold (VIM), optimized for efficient airflow and variable valve timing (VVT) systems, which contribute to enhanced power delivery across the rev range. These components, along with the twin-scroll turbochargers, are crucial for achieving the engine’s characteristic power output and responsiveness. The precision-engineered pistons and connecting rods further optimize combustion efficiency and power output.

Technological Advancements

Compared to previous BMW inline-6 engines, the N55 represented a substantial leap forward in technology. The incorporation of twin-scroll turbochargers was a key innovation, enabling a quicker and more responsive power delivery. The advanced valve timing and variable intake systems significantly improved fuel efficiency and reduced emissions. This engine architecture marked a shift toward a more sophisticated and powerful engine design that addressed the needs of modern drivers.

Performance Characteristics

The N55 engine boasts impressive performance figures. Typical horsepower outputs ranged from 300 to 335 hp, depending on the specific application. Torque figures were equally substantial, often exceeding 300 lb-ft. This combination of power and torque translates to brisk acceleration and responsive driving, making the N55 a popular choice for performance-oriented vehicles. Its power delivery profile is generally linear and smooth, contributing to a pleasurable driving experience.

Comparison to Other BMW Inline-6 Engines

| Engine | Horsepower (hp) | Torque (lb-ft) | Technology |

|---|---|---|---|

| N54 | 300-335 | 258-295 | Naturally Aspirated, Single Turbo |

| N55 | 300-335 | 300+ | Twin-Turbocharged |

| N57 | 300-370 | 332-369 | Twin-Turbocharged, VVT |

This table illustrates the key differences in performance and technology between the N55 and other inline-6 engines produced by BMW. The N55 engine is distinguished by its twin-turbo configuration, resulting in a substantial increase in torque output compared to the naturally aspirated N54. The N57, a later model, represents further advancements in turbocharging and valve timing technology. The different configurations and features of each engine catered to various performance and efficiency needs.

Performance and Driving Experience

The N55 engine, a popular choice for BMW enthusiasts, delivers a dynamic driving experience that balances power and refinement. Its responsive nature and smooth operation make it a joy to drive in various conditions, from bustling city streets to open highways. This section delves into the engine’s performance characteristics, considering its behavior across different driving scenarios and comparing it to other BMW models.

The N55’s architecture allows for a noticeable difference in performance compared to older engine designs. Its direct injection and turbocharging technologies, combined with the engine’s overall architecture, deliver a responsive and powerful experience. The driving experience varies based on the specific trim level, with more powerful versions delivering a noticeably more exhilarating feel.

Responsiveness and Acceleration

The N55 engine exhibits a characteristically quick responsiveness to throttle inputs. This is particularly noticeable in acceleration from a standstill, where the engine’s power delivery is linear and progressive. The turbocharger contributes significantly to this immediate response, delivering torque throughout the rev range. This characteristic is crucial in urban environments, enabling quick lane changes and effortless merging.

Performance Across Driving Conditions

The N55 engine demonstrates impressive performance across a range of driving conditions. In city driving, its responsive nature is ideal for navigating traffic and making quick maneuvers. On highways, the engine maintains a smooth and consistent power output, suitable for long-distance cruising. While the engine isn’t specifically designed for track use, it provides sufficient power and responsiveness for spirited driving on well-maintained roads. The engine’s ability to handle different conditions highlights its versatility.

Sound Characteristics

The N55 engine produces a distinctive sound, often described as a harmonious blend of a turbocharged engine’s growl and a naturally aspirated engine’s smoothness. This sound character varies based on the specific model and engine tuning. The sound profile generally aligns with the overall performance character, providing a clear auditory cue of the engine’s power output and engagement.

Comparison to Other BMW Models

Comparing the N55-powered BMW to other models, like those equipped with different engine configurations, reveals subtle yet important differences. Models with naturally aspirated engines often feel less responsive in acceleration, whereas models with more powerful turbocharged engines tend to exhibit a more aggressive performance profile. The specific characteristics of the N55 engine often align well with the desire for a balanced driving experience.

Performance Comparison Across Trim Levels

| BMW Model | Trim Level | 0-60 mph (seconds) | Top Speed (mph) | Horsepower | Torque (lb-ft) |

|---|---|---|---|---|---|

| 3 Series | Sport | 5.8 | 155 | 300 | 300 |

| 3 Series | Luxury | 6.2 | 150 | 270 | 250 |

| 5 Series | Sport | 5.5 | 160 | 300 | 350 |

The table above provides a general comparison of performance figures for different trim levels of BMW vehicles equipped with the N55 engine. Note that these figures are approximate and may vary based on specific model variations and options. These figures illustrate the varying performance characteristics across different trims and models.

Maintenance and Repair Considerations

The N55 engine, while renowned for its performance, demands a meticulous maintenance schedule and can be susceptible to specific issues. Understanding these aspects is crucial for optimizing its lifespan and preventing costly repairs. Proper maintenance not only enhances reliability but also safeguards the engine’s warranty, ensuring optimal performance throughout its service life.

The N55’s intricate design, incorporating features like twin-scroll turbochargers and high-pressure fuel injection, necessitates a vigilant approach to preventative maintenance. Neglecting routine inspections and replacements can lead to costly breakdowns and reduced performance. This section details the typical maintenance schedule, potential issues, repair procedures, and associated costs, providing a comprehensive guide for N55 owners.

Typical Maintenance Schedule

Maintaining an N55 engine involves a series of scheduled services. Regular oil changes, filter replacements, and fluid checks are paramount. The frequency of these services depends on driving conditions and mileage, typically recommended every 7,500 to 10,000 miles. Other crucial maintenance tasks include inspecting hoses, belts, and coolant levels, and checking the turbocharger’s condition, typically at every 20,000-30,000 miles. Adhering to this schedule ensures the engine operates at peak efficiency and longevity.

Potential Maintenance Issues

Several issues can arise with the N55 engine, ranging from minor inconveniences to more significant problems. One common issue is the failure of the turbocharger, often due to excessive heat or insufficient lubrication. This can lead to reduced power output and potentially catastrophic damage if not addressed promptly. Another issue is the deterioration of hoses and belts, potentially causing leaks or failures. Faulty fuel injectors can also cause rough idling, poor acceleration, and potentially damage to other engine components. In summary, careful attention to these potential issues and their early detection is crucial for preventing major engine problems.

Common Repair Procedures

Various repair procedures address N55 issues. Turbocharger replacement, for example, involves disconnecting the associated hoses, removing the old turbocharger, and installing the new one, meticulously connecting all components. Hose and belt replacements involve similar procedures, replacing damaged parts with OEM components for optimal performance. Fuel injector cleaning or replacement procedures often require specialized tools and diagnostics to pinpoint the faulty components and restore proper functionality. Understanding these procedures enables informed decisions about necessary repairs.

Cost of Repairs and Maintenance

The cost of N55 maintenance and repair varies depending on the specific issue and the chosen repair shop. For instance, a simple oil change typically costs between $100 and $200, whereas a turbocharger replacement can range from $1500 to $3000, potentially exceeding $5000 if additional components need replacing. Replacement of hoses and belts can cost between $200 and $500, while fuel injector cleaning or replacement can range from $300 to $1500. The variability in cost is significant, and it is advisable to seek quotes from multiple reputable mechanics.

Potential Issues and Repair Costs

| Potential Issue | Estimated Repair Cost |

|---|---|

| Oil Leak | $100 – $500 |

| Turbocharger Failure | $1500 – $3000 |

| Hose/Belt Replacement | $200 – $500 |

| Fuel Injector Cleaning | $300 – $1500 |

| Valve Cover Gasket Failure | $200 – $1000 |

Note: Costs are estimates and may vary based on location, labor rates, and specific parts required.

Modifications and Tuning Options

The N55 engine, while renowned for its performance, offers ample opportunities for enhancement through modifications. Owners seeking to extract further power or refine the driving experience can explore various tuning options. These modifications can significantly impact the engine’s output, responsiveness, and overall driving characteristics.

The possibilities for modifying the N55 engine span a wide spectrum, from relatively simple bolt-on upgrades to more complex performance enhancements. This section will explore common modification avenues, their impact on performance, and examples of successful modifications.

Performance Upgrades

Performance upgrades are frequently undertaken to increase horsepower and torque. These modifications often involve a combination of hardware and software adjustments. The extent of the upgrade depends on the desired outcome and the budget allocated. Examples include installing high-flow air filters, performance exhaust systems, and upgraded turbochargers. The result is typically a noticeable increase in power, particularly at higher RPMs, with the potential for improved throttle response.

Tuning Options

Tuning options involve modifying the engine’s electronic control unit (ECU) to optimize its performance. This often entails recalibrating the engine’s fuel delivery, ignition timing, and other parameters to achieve the desired power and efficiency. These modifications can be performed by skilled technicians or using specialized software and hardware. The outcome can range from minor gains in power and torque to substantial improvements in responsiveness.

Examples of Successful Modifications

Many N55 owners have successfully modified their engines, achieving significant performance gains. For instance, some have combined intake upgrades with exhaust systems and ECU tuning to increase horsepower by 50-75 hp. Others have focused on optimizing the turbocharger system for enhanced responsiveness and torque delivery across the RPM range.

Common Modification Parts and Their Effects on Performance

| Modification Part | Effect on Performance |

|---|---|

| High-flow air filter | Improved airflow, potentially increasing horsepower and torque, particularly at higher RPMs. |

| Performance exhaust system | Reduced backpressure, allowing for increased exhaust flow and potential power gains. Can also enhance the engine’s sound. |

| Upgraded turbocharger | Increased airflow and boost pressure, leading to significant gains in horsepower and torque, particularly at higher RPMs. |

| ECU tuning | Optimized fuel delivery, ignition timing, and other parameters for enhanced performance and efficiency. Can produce noticeable improvements in horsepower and torque across the entire RPM range. |

| Cold air intake | Improved air intake temperature and density, leading to slight power gains. Important in hot climates. |

Fuel Efficiency and Emissions

The N55 engine, while renowned for its performance, also presents a nuanced perspective regarding fuel efficiency and emissions. Understanding its fuel consumption patterns and environmental impact is crucial for a comprehensive evaluation of this powertrain. This section delves into the N55’s fuel economy, emissions characteristics, and environmental footprint, offering data-driven insights for informed decision-making.

Fuel Efficiency Comparison

The N55 engine’s fuel efficiency varies depending on several factors, including the specific BMW model, driving style, and external conditions. Generally, the N55, with its turbocharged architecture, exhibits a fuel consumption profile that’s somewhat higher than naturally aspirated engines of comparable power output. However, it often compares favorably to other turbocharged engines from the same era, particularly when optimized for efficiency. This is influenced by factors such as variable valve timing and sophisticated turbocharging systems designed for improved responsiveness and efficiency.

Emissions Characteristics

The N55 engine, while achieving acceptable emissions levels, is not exempt from the challenges associated with modern internal combustion engines. The engine’s emissions profile is governed by various regulatory standards and technological measures. These measures include catalytic converters, particulate filters, and exhaust gas recirculation (EGR) systems to reduce harmful pollutants like NOx and particulate matter. However, emissions can vary based on factors such as driving conditions, vehicle maintenance, and the quality of fuel used.

Environmental Impact

The environmental impact of the N55 engine is a multifaceted issue. While advancements in engine technology have reduced emissions compared to older designs, the engine’s dependence on fossil fuels remains a critical factor. The overall environmental footprint is influenced by the fuel source, the vehicle’s overall design, and the driving habits of the user. Minimizing fuel consumption and optimizing driving practices can contribute to reducing the engine’s environmental impact.

Fuel Consumption Under Different Driving Conditions

Fuel consumption varies significantly based on driving conditions. City driving, with its stop-and-go nature, typically results in higher fuel consumption compared to highway driving. Aggressive acceleration and sustained high speeds also increase fuel consumption. Moderate driving styles and careful acceleration contribute to improved fuel economy. Efficient driving techniques, such as maintaining a consistent speed and avoiding sudden maneuvers, can significantly impact fuel consumption.

Fuel Efficiency Ratings Summary

| BMW Model | Estimated City MPG | Estimated Highway MPG | Estimated Combined MPG |

|---|---|---|---|

| BMW 3 Series (2010-2013) | 18-22 | 28-32 | 22-27 |

| BMW 5 Series (2010-2013) | 17-21 | 27-31 | 21-26 |

| BMW X5 (2010-2013) | 16-20 | 26-30 | 20-25 |

Note: MPG figures are estimates and may vary based on individual driving conditions and vehicle specifications.

Reliability and Durability

The N55 engine, renowned for its potent performance, also faces scrutiny regarding its reliability and durability. While generally robust, inherent design choices and potential maintenance issues can impact long-term performance. Understanding these aspects is crucial for prospective owners and those considering servicing or modifying the engine.

Strengths of the N55 Engine Regarding Reliability

The N55 engine’s strength lies in its relatively straightforward design compared to some contemporary high-performance engines. Its modularity facilitates easier component replacement and maintenance, potentially reducing overall repair costs. The robust construction of key components, such as the crankshaft and connecting rods, contributes to its durability under sustained high-performance use. Furthermore, its relatively common usage in BMW models has facilitated the development of a robust aftermarket support network, ensuring readily available parts and skilled technicians.

Weaknesses and Common Issues

Several weaknesses and common issues associated with the N55 engine have been documented by owners and mechanics. These issues often relate to specific components and are not ubiquitous. One prominent area of concern is the oil pump, which can exhibit issues like premature wear and tear. Another frequently reported problem involves the turbocharger’s oil supply system, which may lead to premature failure if not adequately maintained. Valve train issues, particularly in high-performance or heavily modified applications, are also frequently reported. Furthermore, the high-pressure fuel pump is susceptible to wear and tear, potentially causing fuel delivery problems.

Long-Term Durability

The long-term durability of the N55 engine is contingent on proper maintenance, driving habits, and the level of modification. Owners who adhere to a regular maintenance schedule, including oil changes and component inspections, significantly increase the engine’s lifespan. Aggressive driving styles, frequent hard acceleration, and sustained high-performance use can accelerate wear and tear on various components, potentially reducing the engine’s long-term durability. Properly maintaining the engine and using high-quality components during modifications can mitigate these issues.

Comparison with Competitors

Comparing the N55’s reliability to competitors like the S55 or other high-performance inline-six engines requires careful consideration. While the N55 offers impressive performance, its reported issues, particularly concerning oil pump and turbocharger problems, are more prevalent than in some competitors. However, the N55’s relative simplicity and aftermarket support can still provide an advantage in terms of repair costs and accessibility.

Common N55 Engine Issues and Frequency

| Issue | Frequency (Estimated) | Description |

|---|---|---|

| Oil Pump Failure | Medium | Premature wear and tear, leading to oil pressure issues. |

| Turbocharger Oil Supply Issues | Medium | Insufficient oil flow to the turbocharger, leading to premature failure. |

| Valve Train Problems | Low | Issues related to valve operation, often in modified engines. |

| High-Pressure Fuel Pump Failure | Low | Wear and tear leading to fuel delivery issues. |

| Cooling System Issues | Low | Potential overheating concerns in certain conditions. |

Note: Frequency is an estimated categorization based on reported incidents and forum discussions. Actual frequency can vary depending on individual driving conditions and maintenance practices.

Historical Context and Evolution

The N55 engine, a crucial component in BMW’s lineup, marked a significant advancement in the company’s commitment to performance and efficiency. Its development was a culmination of years of research and engineering, reflecting BMW’s dedication to pushing the boundaries of internal combustion technology. This evolution, from initial concept to production, significantly impacted BMW’s reputation and influenced the automotive industry’s approach to engine design.

Development Timeline

The N55’s journey wasn’t a sudden leap but a carefully orchestrated progression of advancements. The development of the N55 engine was a gradual process, built upon lessons learned from previous engine designs. Its genesis can be traced back to BMW’s ongoing pursuit of higher performance and fuel efficiency.

- Early Stages (Pre-2006): Initial research and development focused on core technologies, including variable valve timing, direct injection, and advanced cylinder head designs. These early concepts laid the groundwork for the sophisticated engine that followed. BMW engineers meticulously tested and refined various components to achieve optimal performance and reliability.

- Prototype Development (2006-2008): This period saw the construction and testing of prototypes, enabling engineers to validate the design’s viability and refine the engine’s performance characteristics. Extensive testing across diverse conditions was crucial in identifying and addressing potential weaknesses. BMW utilized sophisticated dynamometers and simulated driving environments to ensure peak performance in various driving scenarios. Early prototypes incorporated advanced features like variable valve timing, which allowed for optimized airflow and reduced emissions.

- Production Introduction (2008-2013): The successful culmination of the development process led to the N55 engine’s introduction into various BMW models. This marked a significant step for BMW, as the N55 represented a considerable advancement over previous generations. The N55’s introduction boosted BMW’s reputation for innovative and high-performing engines. Significant advancements in materials and manufacturing techniques ensured production efficiency and quality control. The adoption of the engine across different models showcased BMW’s commitment to providing a diverse range of powertrain options to meet varying customer demands.

- Refinement and Iteration (2013-Present): Even after the N55’s introduction, BMW continued to refine and improve the design, incorporating feedback from various sources, including customers and racing teams. Subtle improvements in components and software tuning continued to enhance the engine’s performance and efficiency. This ongoing refinement reflects BMW’s commitment to continuous improvement and adaptation to changing customer needs.

Impact on BMW Brand

The N55 engine significantly impacted the BMW brand’s reputation. Its introduction underscored BMW’s commitment to innovative engineering and performance-oriented designs. This engine became synonymous with a driving experience characterized by impressive acceleration, responsive handling, and a refined power delivery. The engine’s positive reception reinforced BMW’s position as a leading innovator in the automotive industry.

Significance in the Automotive Industry

The N55 engine’s impact extended beyond BMW. Its introduction of advanced technologies, such as direct injection and variable valve timing, influenced other manufacturers. The engine’s fuel efficiency and performance standards served as a benchmark for other engine designs. This exemplified BMW’s leadership role in shaping the future of automotive engineering.

Applications and Models

The N55 engine, a potent and refined powerplant, played a significant role in BMW’s lineup. Its widespread adoption across various models underscores its performance capabilities and adaptability. This section delves into the specific BMW models that utilized the N55, the different configurations it took on, and its performance characteristics in those applications.

BMW Models Equipped with the N55 Engine

The N55 engine powered a range of BMW models, reflecting its versatility and suitability for different performance demands. Its application encompassed a spectrum of vehicles, from sporty coupes to luxurious sedans.

- 3 Series Sedan (E90, E92, and E93): The N55 was a popular choice for the 3 Series, particularly in its performance-oriented variants. The engine offered a balance of power and efficiency, making it well-suited to this popular model range.

- 4 Series Coupe (F32, F33, F36): The 4 Series benefited from the N55’s refined power delivery and responsive handling. The engine provided a compelling combination of performance and refinement in the sporty coupe segment.

- 5 Series Sedan (F10): The N55 engine was used in some 5 Series models, offering a more accessible performance option in this luxury segment. It demonstrated BMW’s commitment to providing choices in performance levels across their range.

- X5 (E70): The N55’s use in the X5 reflected its ability to handle increased torque requirements in an SUV application. It showcased the versatility of the engine design, adapting to the demands of a larger vehicle.

N55 Engine Configurations

The N55 engine was available in various configurations to meet the specific needs of different BMW models. These variations in displacement and power output were crucial in adapting the engine’s performance to the model’s intended use.

- Displacement Variations: The N55 engine came in various displacement options, impacting its output and torque characteristics. This flexibility enabled BMW to offer tailored performance options across different model lines.

- Turbocharger Configurations: The use of turbocharging in the N55 engine was crucial for achieving high performance and efficiency. Variations in turbocharger design and placement optimized performance characteristics across various models.

- Output Variations: Specific models utilized different power output variants of the N55 engine. This enabled BMW to cater to different performance preferences within the same model range.

Performance in Different Applications

The N55 engine’s performance varied based on the specific model and configuration. Factors like displacement, turbocharger type, and tuning played a significant role in achieving different performance characteristics.

- 3 Series: The N55 in the 3 Series offered a dynamic driving experience, providing substantial power and responsiveness in a compact package.

- 5 Series: The N55 in the 5 Series provided a balance between performance and refinement, demonstrating the engine’s versatility in a more luxurious setting.

- X5: The N55 in the X5 delivered a capable performance, demonstrating the engine’s suitability for the demands of an SUV, balancing power with drivability.

Overall Usage of the N55 Engine

The N55 engine’s widespread use across various BMW models showcased its broad applicability. Its combination of power, efficiency, and refinement made it a valuable engine for BMW.

Table: BMW Models with N55 Engine Specifications

| BMW Model | Engine Configuration | Power Output (hp) | Torque (lb-ft) |

|---|---|---|---|

| 3 Series (E90/E92/E93) | 3.0L TwinPower Turbo | 300-335 | 300-332 |

| 4 Series Coupe (F32/F36) | 3.0L TwinPower Turbo | 300-335 | 300-332 |

| 5 Series (F10) | 3.0L TwinPower Turbo | 300 | 300 |

| X5 (E70) | 3.0L TwinPower Turbo | 300 | 300 |

Images and Visualizations

The N55 engine’s intricate design, featuring a high-performance powertrain, demands visual representation for complete understanding. Visual aids provide a comprehensive overview of the engine’s internal components and layout, enhancing comprehension of its functionality and design choices. This section details the engine’s internal components, layout, and key design features, aiding in grasping its complexity and performance.

Internal Component Visualization

The N55 engine’s internal structure comprises a sophisticated arrangement of interconnected parts. Imagine a series of precisely engineered components working in harmony. The crankshaft, connected to the pistons, converts the reciprocating motion of the pistons into rotational energy. Connecting rods transmit this force, ensuring smooth power delivery. The camshaft, positioned above the cylinder head, synchronizes the opening and closing of the intake and exhaust valves, enabling controlled airflow. The intricate interplay of these components generates the engine’s power output.

Engine Layout and Components

The N55 engine’s layout is characterized by its inline six-cylinder configuration. This design places the cylinders in a straight line, optimizing space and balancing the engine’s mass. The engine block, a crucial component, houses the cylinders and provides structural support. The cylinder head, atop the block, contains the combustion chambers and the valves, regulating the flow of air and fuel. Visualizing the precise arrangement of these components provides a clear understanding of the engine’s functionality.

Cooling System

The N55’s cooling system is designed for optimal performance under demanding conditions. The coolant circulates through passages within the engine block and cylinder head, absorbing heat generated during combustion. This efficient heat transfer prevents overheating, ensuring consistent engine operation. A radiator, external to the engine, further dissipates excess heat into the surrounding air, maintaining ideal operating temperatures.

Intake Manifold

The intake manifold’s design is critical for efficient airflow to the cylinders. It directs the intake air to each cylinder, ensuring a consistent and optimized air-fuel mixture. This manifold is often optimized for specific performance characteristics.

Exhaust System

The exhaust system manages the expulsion of combustion gases from the engine. Exhaust manifolds collect the gases from each cylinder and route them to a catalytic converter. This converter reduces harmful emissions. The exhaust system is designed to minimize backpressure and maximize efficiency.

Engine Block Construction

The engine block, the foundational component of the N55, is crafted from high-strength aluminum alloy. This material offers a balance between strength and lightweight construction, improving performance and efficiency. The block’s intricate casting process ensures precise tolerances, contributing to the engine’s overall durability.

Cylinder Head Construction

The cylinder head, directly above the engine block, is also constructed from aluminum alloy. This material contributes to the engine’s overall lightweight design, minimizing inertia. The cylinder head’s design includes precise porting and valve arrangements, crucial for optimized airflow.

Engine Component Table

| Component | Description | Material |

|---|---|---|

| Crankshaft | Rotates to convert piston motion to power. | Steel Alloy |

| Connecting Rods | Transmit force from pistons to crankshaft. | Steel Alloy |

| Piston | Moves up and down within the cylinder. | Aluminum Alloy |

| Camshaft | Controls valve timing. | Steel Alloy |

| Valves | Open and close to regulate airflow. | Steel Alloy |

| Engine Block | Houses cylinders and components. | Aluminum Alloy |

| Cylinder Head | Contains combustion chambers and valves. | Aluminum Alloy |