BMW Part Types

BMW vehicles are renowned for their engineering precision and performance, demanding high-quality components. Understanding the diverse range of parts used in these vehicles is crucial for maintenance, repair, and even appreciation of their intricate design. This exploration delves into the various types of BMW parts, categorized by their function and the materials used in their construction.

BMW parts are meticulously designed and manufactured to meet stringent quality standards, ensuring optimal performance and longevity. The materials employed in their production significantly influence their durability and functionality. Different manufacturing processes are also utilized, reflecting the complexity and precision required for each part.

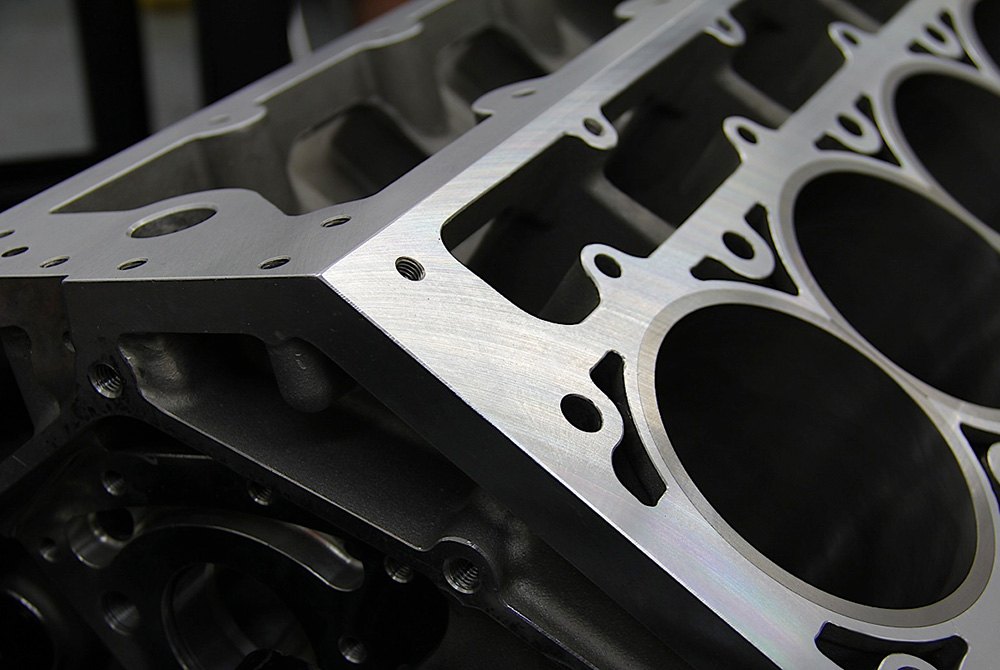

BMW Engine Components

BMW engines are complex assemblies, incorporating a wide variety of parts. The durability of these components is crucial for vehicle performance and longevity. Engine parts are designed to withstand considerable stress and pressure, ensuring reliable operation under demanding conditions.

- Engine Block: Typically constructed from cast iron or aluminum alloy, the engine block is the foundational component. Its strength and rigidity are vital for housing the engine’s internal mechanisms and withstanding high operating temperatures. Aluminum alloys are increasingly used for their lighter weight and improved heat dissipation.

- Pistons: Engine pistons are crucial for converting the pressure of combustion into mechanical energy. They are often made from aluminum alloys for their lightweight nature, which improves engine performance. Sophisticated coatings and designs enhance their durability against wear and tear.

- Crankshaft: The crankshaft is a critical component responsible for transferring the rotational energy generated by the pistons to the transmission. It is usually constructed from high-strength steel alloys for their resistance to fatigue and twisting forces.

- Valves: Engine valves regulate the flow of air and fuel into and out of the combustion chambers. Their durability is critical to ensure smooth operation and prevent premature wear. They are typically made from hardened steel alloys for resistance to high temperatures and pressures.

BMW Transmission Components

The transmission system plays a crucial role in transferring power from the engine to the wheels. Its components must withstand significant mechanical stress and variations in operating conditions. Materials and manufacturing processes are carefully selected to meet these demands.

- Gear Set: Gears within the transmission are vital for power transmission. Precision-machined steel gears, often with heat treatments, ensure durability and longevity. Their precise tolerances are critical for smooth and efficient gear engagement.

- Clutch System: The clutch system enables the smooth engagement and disengagement of the transmission. Components like the clutch disc and pressure plate are made from materials that can withstand the friction and pressure generated during operation. Friction materials are carefully selected to optimize engagement and prevent slippage.

BMW Brake Components

Brake components are critical for vehicle safety and must maintain consistent performance under varying conditions. The materials used and the manufacturing processes employed significantly affect their lifespan and effectiveness.

- Brake Rotors: Brake rotors are subjected to high temperatures and friction during braking. They are typically made from cast iron or steel alloys, often with heat-treated surfaces for enhanced durability and resistance to warping. The choice of material and heat treatment process is crucial for preventing brake fade and maintaining stopping power.

- Brake Pads: Brake pads are friction materials that generate the braking force. Their composition is carefully formulated to achieve optimal braking performance, balance durability, and resistance to wear. The compounds used can vary depending on the type of braking system.

BMW Suspension Components

The suspension system of a BMW is designed to provide a smooth and controlled ride while absorbing road shocks. Different components are made from various materials depending on their specific function.

- Springs: Springs, crucial for controlling vehicle bounce, are commonly made from steel alloys. Their strength and stiffness are critical to ensure a comfortable and controlled ride.

- Shock Absorbers: Shock absorbers dampen oscillations and maintain vehicle stability. Their construction involves carefully selected materials and precise manufacturing techniques to ensure optimal performance and durability.

Durability Comparison of BMW Engine Components

| Component | Material | Durability (Estimated based on service life) |

|---|---|---|

| Engine Block | Cast Iron/Aluminum Alloy | High (typically 100,000-150,000 miles or more, depending on maintenance and driving conditions) |

| Pistons | Aluminum Alloy | Moderate to High (typically 100,000-150,000 miles or more, depending on maintenance and driving conditions) |

| Crankshaft | High-Strength Steel Alloy | High (typically 100,000-150,000 miles or more, depending on maintenance and driving conditions) |

| Valves | Hardened Steel Alloy | Moderate to High (typically 100,000-150,000 miles or more, depending on maintenance and driving conditions) |

Note: Durability estimates are approximate and can vary based on factors like driving style, maintenance, and environmental conditions.

BMW Part Sourcing

Securing the correct BMW parts is crucial for maintaining vehicle performance and reliability. Understanding the various sourcing options—from authorized dealerships to independent aftermarket suppliers—is essential for informed decision-making. This section details the available channels, compares pricing models, and highlights the critical aspect of compatibility.

BMW Part Sourcing Channels

BMW parts can be acquired through diverse channels, each with its own advantages and disadvantages. Dealerships, online retailers, and aftermarket suppliers represent the primary avenues for part procurement.

- Dealerships: Authorized BMW dealerships provide genuine OEM parts. This ensures precise fit and functionality, aligning with BMW’s specifications. However, these parts typically come with a higher price tag.

- Online Retailers: E-commerce platforms offer a wide selection of BMW parts, often at competitive prices. This allows for convenient comparison shopping across various vendors.

- Aftermarket Suppliers: These suppliers provide a diverse range of BMW parts, frequently at lower costs than OEM parts. The quality and compatibility of aftermarket parts can vary significantly, requiring thorough research and verification.

OEM vs. Aftermarket Part Pricing and Availability

The cost and availability of OEM and aftermarket parts differ substantially. OEM parts, directly from the manufacturer, maintain superior quality and compatibility. However, their price point reflects the manufacturer’s production costs and quality control.

Aftermarket parts offer a more affordable alternative. The availability of aftermarket parts is generally higher, encompassing a broader range of models and years. However, ensuring compatibility and quality necessitates careful selection and vendor research.

Part Compatibility

Accurate part compatibility is paramount when replacing BMW parts. Incorrect parts may lead to suboptimal performance, safety issues, and potential damage to the vehicle’s system. It is crucial to cross-reference part numbers and specifications with the vehicle’s maintenance manual or an authorized source.

A mismatched part might not properly integrate with the existing system, causing performance issues, or even pose safety risks. Therefore, validating compatibility is paramount to avoid these issues.

Comparison Table of BMW Part Sourcing

| Source | Pros | Cons |

|---|---|---|

| Dealerships | Genuine OEM parts, guaranteed fitment, warranty coverage | Higher prices, limited availability of certain parts |

| Online Retailers | Competitive pricing, wide selection, convenience of online shopping | Potential for counterfeit parts, varying quality control, need for compatibility verification |

| Aftermarket Suppliers | Lower prices, greater availability, broader selection of parts | Potential for lower quality parts, less warranty coverage, risk of incompatibility |

BMW Part Identification

Accurate identification of BMW parts is crucial for ensuring compatibility and proper function. Incorrect parts can lead to costly repairs and potentially compromise vehicle safety. This section details methods for identifying genuine BMW parts, determining the correct part for a specific model and year, and utilizing resources to locate part numbers.

Identifying genuine BMW parts involves meticulous attention to detail. Authenticity is vital, as aftermarket parts may not meet the same standards of quality and performance. Proper identification minimizes the risk of compatibility issues and ensures optimal vehicle operation.

Genuine Part Identification

Genuine BMW parts are marked with specific identifiers to ensure authenticity. These markings often include part numbers, which are crucial for matching parts to the correct vehicle model and year. Visual inspection for BMW logos, stamps, or specific codes on the part itself is essential. Furthermore, checking the part against official BMW documentation or a trusted parts catalog is necessary.

Determining the Correct Part

Precise determination of the correct part is essential for optimal vehicle function. This requires accurate model and year identification. For instance, a part for a 2018 BMW 3 Series will likely differ from a part for a 2023 model. Online resources, dealer catalogs, and repair manuals provide crucial information to match parts to the specific vehicle.

Role of Diagrams and Schematics

Diagrams and schematics are invaluable tools in identifying BMW parts. These visual representations illustrate the location and function of various components within the vehicle. Schematics often include part numbers, making it easier to match parts with the correct vehicle model and year. For example, a wiring diagram can help pinpoint the correct electrical component for a particular function. Comprehensive diagrams, including exploded views of assemblies, allow for a complete understanding of the vehicle’s design and the specific location of parts.

Using Online Resources

Online resources are vital for locating BMW part numbers. BMW’s official website, along with authorized dealer websites and reputable online parts retailers, offer extensive databases. These databases allow users to search for specific parts using various criteria, including vehicle model, year, and part description. Specialized online tools can further assist in finding compatible parts and confirming authenticity. For example, searching for “BMW 2020 X5 brake caliper part number” on a reputable website will yield the specific part number for the brake caliper on that model year. Furthermore, many online forums dedicated to BMW owners provide valuable insights and recommendations for identifying parts.

BMW Part Installation

Proper BMW part installation is crucial for maintaining vehicle performance, safety, and longevity. Incorrect installation can lead to malfunctioning components, increased wear and tear, and even potential safety hazards. Following the correct procedures and using the appropriate tools ensures a reliable and lasting repair.

A thorough understanding of the specific part’s installation process, including the necessary tools and potential variations in installation methods, is essential for a successful repair. This involves recognizing the nuances in various BMW models and ensuring compatibility with the vehicle’s specific design.

Brake Pad Replacement Procedure

Replacing brake pads is a relatively common maintenance task. Properly replacing brake pads ensures optimal braking performance and extends the life of your brake system. The following steps detail a typical procedure for replacing brake pads on a BMW.

- Gather necessary tools and materials. This includes a torque wrench, various sockets and wrenches, a hammer, a pry bar, and the new brake pads. Ensure the correct brake pad set for your specific BMW model is acquired to avoid compatibility issues.

- Locate the brake calipers. Carefully examine the front or rear brake calipers. Identify the necessary fasteners for securing the caliper to the brake rotor.

- Remove the old brake pads. Using the appropriate tools, carefully remove the old brake pads from the calipers. Pay close attention to any retaining clips or springs that may be involved in the process.

- Inspect and clean the brake calipers. Thoroughly inspect the brake calipers for any damage or wear. Clean the caliper surfaces to ensure proper contact with the new brake pads.

- Install the new brake pads. Carefully align the new brake pads with the caliper and ensure they are seated correctly. Secure the new brake pads in place using the appropriate retaining clips or springs.

- Reinstall the brake calipers. Carefully reattach the brake calipers to the brake rotor. Ensure all fasteners are tightened to the manufacturer’s specifications using a torque wrench.

- Bleed the brake system. Bleed the brake system to remove any trapped air, which can affect braking performance. Consult your BMW’s owner’s manual for the specific bleeding procedure.

- Test the brakes. After installation, thoroughly test the braking system to confirm proper functionality and responsiveness.

Engine Component Installation

Engine component replacement requires specialized knowledge and tools. Careful attention to detail and adherence to manufacturer specifications are critical. The procedure for installing a specific engine component, such as a crankshaft bearing, will differ from replacing a fuel injector.

- Engine Component Selection. Confirm the correct engine component for your specific BMW model and engine type. Incorrect parts will lead to compatibility issues and potential damage. Reference the parts catalog or owner’s manual for verification.

- Disconnect and secure necessary connections. Disconnect any electrical connections, fuel lines, or other components related to the engine component being replaced. Secure these disconnected components to prevent accidental damage during the replacement process.

- Remove the old component. Carefully remove the old engine component, ensuring proper handling and safety precautions. Note the specific installation points and orientation of the component.

- Install the new component. Carefully align the new engine component with the corresponding mounting points and secure it using the appropriate fasteners. Follow the manufacturer’s instructions and torque specifications.

- Reconnect and test. Reconnect all electrical connections, fuel lines, and other components. Thoroughly test the engine’s functionality to ensure proper operation and avoid potential issues.

Tools and Equipment

The required tools and equipment vary significantly depending on the specific BMW part being installed. Appropriate tools and equipment are critical to ensure a safe and effective installation process. Common tools include:

| Part | Tools |

|---|---|

| Brake Pads | Torque wrench, sockets, wrenches, hammer, pry bar |

| Engine Components | Engine hoist, specialized sockets, torque wrench, various hand tools, safety equipment |

BMW Part Maintenance

Maintaining a BMW involves more than just driving; it’s about proactively caring for its intricate components. Regular maintenance ensures optimal performance, longevity, and a safe driving experience. Proper care extends beyond the obvious, encompassing a range of procedures that prevent potential issues and preserve the vehicle’s value.

Regular maintenance of BMW parts goes beyond simply changing the oil. It encompasses a comprehensive approach to inspections, replacements, and diagnostics. A well-maintained BMW is a reliable and enjoyable vehicle, minimizing the risk of unexpected breakdowns and costly repairs.

Routine Maintenance Schedule

Understanding the recommended maintenance schedule is crucial for preserving the longevity and performance of your BMW. Adhering to this schedule ensures that critical components are maintained within optimal parameters.

- Oil Changes: Oil changes are critical for lubrication and preventing wear and tear on engine components. Frequency varies based on the specific BMW model and driving conditions, but generally falls between 7,500 to 15,000 miles. Using the correct viscosity grade of oil is essential, as specified in the owner’s manual.

- Filter Replacements: Air filters, fuel filters, and cabin air filters all play vital roles in maintaining optimal engine function and passenger comfort. Regular replacement of these filters, as recommended in the owner’s manual, is critical for efficient performance. Clogged filters can lead to reduced performance and potential engine damage.

- Brake Fluid Checks and Replacements: Brake fluid degrades over time and absorbs moisture. This can affect the braking system’s performance and safety. Brake fluid should be checked and replaced according to the manufacturer’s recommendations.

- Coolant Checks and Replacements: Coolant protects the engine from overheating and corrosion. Regular checks and replacements of coolant, following the manufacturer’s guidelines, are vital to prevent overheating issues.

- Tire Rotations and Pressure Checks: Regular tire rotations and pressure checks are essential for even wear and improved handling. Maintaining proper tire pressure also enhances fuel efficiency.

Importance of Regular Inspections

Regular inspections are not just about preventing problems; they are proactive steps to maintain the integrity of your BMW’s components. Early detection of potential issues saves money and minimizes the risk of significant failures.

- Visual Inspections: Regular visual checks of various components, such as hoses, belts, and connections, can reveal potential issues before they escalate into more costly repairs. Visual inspections are often combined with other checks to ensure comprehensive evaluation.

- Diagnostics: Utilizing diagnostic tools to assess the operational status of the vehicle’s electrical and mechanical systems can provide early warnings of developing problems.

Causes of Common BMW Part Failures

Several factors contribute to the deterioration and failure of BMW components. Understanding these causes allows for proactive measures to mitigate their impact.

- Wear and Tear: Prolonged use and exposure to environmental conditions inevitably lead to wear and tear on components like engine parts, brakes, and suspension systems.

- Inadequate Maintenance: Neglecting scheduled maintenance, such as oil changes and filter replacements, accelerates the wear and tear process, leading to premature failures.

- Driving Habits: Aggressive driving styles, including harsh acceleration and braking, can put excessive stress on components, leading to quicker deterioration.

- Environmental Factors: Exposure to extreme temperatures, harsh weather conditions, and corrosive substances can contribute to the premature failure of various parts.

Proper Inspection of Brake Components

Regular inspection of brake components is critical for safety. Visual inspection and functional testing are essential for detecting potential problems.

| Component | Inspection Procedure |

|---|---|

| Brake Pads | Visually inspect for thickness, wear, and damage. Measure pad thickness with a gauge. |

| Brake Rotors | Inspect for warping, grooves, or scoring. Check for even wear patterns. |

| Brake Calipers | Examine for proper operation and alignment. Inspect for any signs of leakage or damage. |

| Brake Lines | Inspect for any cracks, corrosion, or leaks. Check for proper connections. |

BMW Part Diagrams and Schematics

BMW part diagrams and schematics are crucial tools for technicians, mechanics, and DIY enthusiasts working on BMW vehicles. These visual representations detail the placement and connections of various components within the vehicle’s systems, facilitating accurate identification, troubleshooting, and repair procedures. Proper understanding of these diagrams is essential for efficient and safe maintenance and repair.

Engine Bay Component Diagram

Understanding the precise location of each component within the engine bay is critical for efficient repair and maintenance. A comprehensive diagram showcasing the engine bay layout would include a clear representation of the engine, transmission, cooling system, electrical components, and various hoses and belts. This diagram would use standardized symbols to represent each component, ensuring clarity and consistency. For instance, the diagram would clearly indicate the position of the alternator, starter motor, fuel injectors, and air intake system. Detailed labeling of each part is essential for quick identification.

BMW Electrical System Schematic

BMW electrical systems are complex, incorporating various components and intricate wiring harnesses. A schematic diagram would provide a visual representation of the electrical system’s layout, detailing the pathways of power flow and the connections between various components. This schematic would highlight critical components such as the battery, fuse box, alternator, starter motor, and various sensors. The diagram would use standardized symbols for electrical elements, including resistors, capacitors, and relays. Clear labeling of the electrical connections would be crucial to avoid errors during repair.

Significance of Part Numbers in BMW Diagrams

Part numbers are critical elements in BMW diagrams, acting as unique identifiers for specific components. These numbers are essential for ordering the correct replacement parts, ensuring compatibility and performance. A part number will correspond to a specific part’s design, specifications, and compatibility with the vehicle’s system. BMW utilizes a standardized part numbering system that ensures accurate part identification and order placement. Using the incorrect part number can lead to system malfunctions or damage to other components.

Critical BMW Parts Location Table

The following table illustrates the location of critical parts within a specific BMW model (e.g., 2020 BMW 3 Series). This table is not exhaustive, but it highlights critical components and their general locations within the vehicle.

| Part Name | System | Location |

|---|---|---|

| Engine | Powertrain | Front of vehicle, under the hood |

| Transmission | Powertrain | Behind the engine |

| Battery | Electrical | Under the hood, or in the trunk in some models |

| Alternator | Electrical | Near the engine |

| Fuel Pump | Fuel System | Near the fuel tank |

| Brake Pads | Braking System | On brake calipers |

This table provides a basic overview of critical part locations. A comprehensive diagram would provide more precise details for specific parts and their precise locations. Precise location is critical for repair and maintenance, avoiding damage to other parts.

BMW Part Troubleshooting

Troubleshooting BMW parts involves a systematic approach to diagnose and resolve issues. Proper identification of the problem is crucial for effective repair. A thorough understanding of the vehicle’s systems and potential failure points is essential for accurate diagnosis and efficient repair. This includes examining component interactions and their influence on overall system performance.

Diagnosing issues with BMW parts requires a blend of technical expertise, diagnostic tools, and a methodical approach. This process is often iterative, involving multiple steps to isolate the root cause of the problem. By following a structured troubleshooting process, technicians can effectively pinpoint the source of the malfunction and ensure a lasting repair.

Engine Misfiring

Engine misfiring presents as an irregular running condition, often characterized by a rough idle, hesitation, or a sputtering sound. Understanding the possible causes is crucial for accurate diagnosis.

- Spark Plug Issues: Worn or damaged spark plugs can impede proper combustion, leading to misfires. This often manifests as a noticeable loss of power or a rough idle. A visual inspection of the spark plugs, along with checking the spark plug gap, can confirm or rule out this cause.

- Fuel Delivery Problems: Insufficient fuel delivery or improper fuel mixture can also lead to misfiring. This may be caused by a faulty fuel pump, clogged fuel injectors, or a problem with the fuel pressure regulator. Checking fuel pressure and injector functionality are vital diagnostic steps.

- Ignition System Malfunctions: Issues with the ignition system, such as a faulty ignition coil, distributor, or ignition module, can disrupt the spark timing. This often leads to intermittent misfires and can be diagnosed through a thorough inspection of the ignition components.

- Air Intake Problems: Air leaks in the intake system or issues with the mass airflow sensor (MAF) can affect the air-fuel mixture, causing misfires. Using a diagnostic scanner to check the MAF sensor readings can help pinpoint this problem.

Transmission Problems

Transmission problems in BMW vehicles can manifest in various ways, from slipping gears to complete failure. Understanding the potential causes is key to effective diagnosis.

- Fluid Leaks: Low transmission fluid levels due to leaks from the transmission pan or seals can cause slipping or damage internal components. Checking for leaks and ensuring adequate fluid levels is a critical first step.

- Internal Component Damage: Worn or damaged internal components like clutches, gears, or bands within the transmission can lead to slipping or rough shifting. Advanced diagnostics might be necessary to identify these issues.

- Electrical Issues: Problems with the transmission control module (TCM) or related wiring can lead to shifting issues or transmission malfunctions. Using a diagnostic scanner to check TCM codes is a key diagnostic step.

- Mechanical Wear: Mechanical wear and tear, including worn synchronizers or damaged gear teeth, can cause problems with shifting smoothness and engagement. This is a common cause in older vehicles.

Diagnostic Tools and Methods

BMW vehicles often require specialized diagnostic tools for accurate troubleshooting.

- Diagnostic Scanners: Modern diagnostic scanners are essential for reading fault codes, retrieving data, and performing various tests on BMW systems. Specific BMW diagnostic software can help in interpreting the codes and identifying potential causes.

- Specialized Instruments: Using specialized instruments, such as pressure gauges, oscilloscopes, and multimeter, to test specific components can provide a deeper understanding of the problem. Measuring voltage, current, or pressure can be crucial in identifying electrical or mechanical issues.

- Visual Inspection: Thorough visual inspection of the affected components and related areas can reveal leaks, damage, or loose connections. This is often a critical initial step in the troubleshooting process.

Cooling System Problems

Cooling system problems in BMW vehicles often lead to overheating issues. Understanding the potential causes is critical.

- Fluid Leaks: Leaks in the cooling system, such as radiator hoses, water pump seals, or the coolant reservoir, can lead to coolant loss, resulting in overheating.

- Blocked Radiators: Blocked or clogged radiators due to debris or mineral deposits restrict airflow and hinder proper cooling. This is a common issue in older vehicles that have not had regular maintenance.

- Faulty Thermostat: A faulty thermostat that doesn’t open at the appropriate temperature can prevent proper cooling and cause overheating.

- Damaged Water Pump: A damaged water pump, which is responsible for circulating coolant, can impair the cooling system’s effectiveness.

BMW Part Images and Illustrations

Visual representations of BMW parts are crucial for accurate identification, repair, and maintenance. Detailed images and illustrations allow technicians and enthusiasts to understand the intricate design and function of various components. High-quality visuals aid in troubleshooting, guiding repair procedures, and enhancing the overall understanding of BMW mechanical systems.

Engine Component: Cylinder Head

The cylinder head, a vital component of the BMW engine, houses the combustion chambers. Its intricate design accommodates valves, spark plugs, and coolant passages. The head’s material is typically aluminum alloy, known for its strength and thermal conductivity. Precise machining ensures optimal combustion and minimal heat loss. Critical features include precisely positioned valve seats and guides, enabling efficient valve operation and minimizing leakage. The cylinder head’s design directly impacts engine performance and efficiency.

BMW Suspension System

The BMW suspension system is a complex network of components designed for optimal handling and ride comfort. It comprises various parts working in harmony to control the vehicle’s interaction with the road surface. Key components include:

- Springs: These components absorb road shocks and maintain the vehicle’s ride height. Different spring types, such as coil springs, contribute to the desired handling characteristics.

- Dampers (Shock Absorbers): Dampers control the movement of the springs, suppressing oscillations and providing a smooth ride. Their design and adjustment are critical for both ride comfort and handling stability.

- Control Arms: These components connect the suspension to the chassis, enabling controlled movement and preventing excessive wear.

- Steering Linkage: The steering linkage connects the steering wheel to the suspension, allowing precise control of the vehicle’s direction.

- Ball Joints: These components provide smooth articulation between the control arms and the suspension, allowing for the necessary flexibility during movement.

- Anti-roll Bars: These bars prevent excessive body roll during cornering, enhancing stability and control.

- Wheel Bearings: Wheel bearings support the wheels and ensure smooth rotation, reducing friction and noise.

BMW Interior Parts: Dashboard

The dashboard is a central control panel within the BMW interior, housing various instrument gauges, controls, and information displays. Its design is not only functional but also aesthetically integrated into the vehicle’s overall design. Materials used in dashboard construction often include high-quality plastics, metals, and leather accents. The layout of controls is ergonomically designed for ease of use and intuitive operation.

BMW Interior Parts: Seats

BMW seats are designed for both comfort and support, crucial for driver and passenger safety and well-being. The materials used in seat construction include high-quality leather, fabrics, and synthetic materials, contributing to both aesthetic appeal and durability. The seat’s design and construction are carefully tailored to provide ample support for the driver and passengers. Adjustable features like lumbar support and seat position are designed for optimal comfort during extended periods of driving.

BMW Brake Caliper

A brake caliper is a critical component of a vehicle’s braking system. It uses hydraulic pressure to apply force to brake pads, which then grip the brake rotors. The caliper’s design typically includes a piston mechanism, allowing for the controlled application of force. Materials used in caliper construction are chosen for their strength and resistance to heat. The construction of the caliper includes the necessary channels and ports for the flow of brake fluid, which is essential for efficient operation. Brake calipers are designed for reliable and consistent performance.