- Introduction to BMW Jack Pads

- Features and Benefits of BMW Jack Pads

- Types and Selection of BMW Jack Pads

- Safety Precautions and Correct Usage

- Installation and Removal Procedures

- Troubleshooting and Maintenance

- Examples of BMW Jack Pad Applications

- Alternatives and Comparisons

- Deep Dive into Material Properties

Introduction to BMW Jack Pads

BMW jack pads are specialized undercarriage support devices crucial for safely lifting and supporting BMW vehicles during maintenance tasks. Proper use of these pads prevents damage to the vehicle’s chassis and ensures the safety of the mechanic. They distribute the weight of the vehicle evenly across the lifting points, minimizing stress on critical components.

These pads are essential for a wide range of maintenance procedures, including tire changes, brake inspections, and suspension work. Their specific design caters to the unique structure of BMW vehicles, ensuring the safety and integrity of the car during these procedures. This is critical for avoiding potential issues such as frame damage, suspension component strain, and uneven lifting.

Typical Use Cases

BMW jack pads are indispensable for various maintenance tasks. They are employed during tire changes to prevent damage to the vehicle’s undercarriage and ensure the integrity of the lifting points. Furthermore, they are essential for brake inspections, enabling safe access to the brake components. They also support the vehicle during suspension work, preventing potential damage to the suspension system and its components.

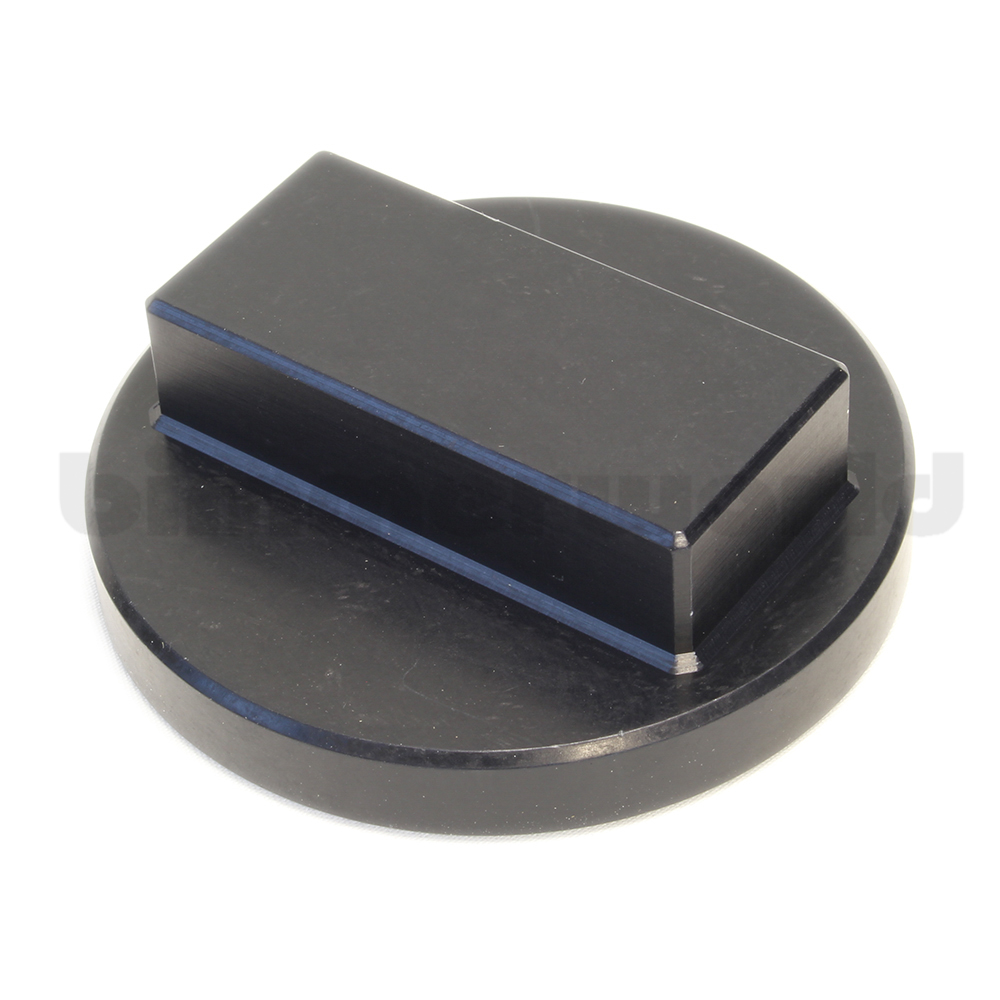

Common Features and Characteristics

BMW jack pads typically exhibit several key features designed for optimal safety and performance. They are engineered to distribute weight evenly, preventing localized stress and damage. High-quality materials are used to ensure durability and resistance to deformation under load. Specific shapes and contours may vary depending on the model and the desired lifting points, allowing for a secure and stable lifting posture. These characteristics guarantee the vehicle’s structural integrity and the safety of the mechanic performing the maintenance task.

Importance of Using Appropriate Jack Pads

Employing appropriate jack pads for BMW vehicles is critical for several reasons. Improper jacking can lead to significant damage to the vehicle’s undercarriage, potentially resulting in costly repairs. Moreover, improper lifting procedures can compromise the safety of the mechanic. Using specialized jack pads designed for BMW vehicles ensures the vehicle’s components are supported correctly and prevents unintended consequences.

Different Types of BMW Jack Pads

The selection of the right jack pad is essential for safe and efficient maintenance. Different materials and designs cater to specific needs. The table below Artikels the common types of BMW jack pads:

| Type | Material | Typical Use Cases | Advantages | Disadvantages |

|---|---|---|---|---|

| Rubber Jack Pads | Rubber | General maintenance, tire changes | Good cushioning, provides protection against scratches, relatively inexpensive | May not be suitable for heavy lifting, can compress under high pressure, may lose their shape over time |

| Metal Jack Pads | Steel, Aluminum | Heavy-duty lifting, professional use | High durability, withstands high pressure, maintains shape over time | More expensive, may scratch the vehicle’s undercarriage if not used carefully |

Features and Benefits of BMW Jack Pads

BMW jack pads are crucial for safe and efficient vehicle maintenance, especially for models like BMWs known for their intricate designs and complex suspension systems. Properly selected and used jack pads prevent damage to the vehicle’s undercarriage, ensuring the longevity and structural integrity of the car. Their careful engineering and material choices are essential for supporting the weight of the vehicle during lifting, and the precise design considerations cater to the unique characteristics of BMWs.

Effective jack pads are engineered to distribute the weight of the vehicle evenly, preventing localized stress and potential damage to the chassis. This distribution is essential for maintaining the vehicle’s structural integrity and preventing long-term issues. The benefits extend beyond simply supporting the car; they provide a stable platform for safe and effective maintenance tasks.

Crucial Features for Effective BMW Jack Pads

BMW jack pads must be specifically designed to accommodate the unique chassis structures and suspension designs of BMW models. This often includes specific shapes and sizes for various points on the car. The pads must also provide a stable and secure lifting platform, preventing any movement or slippage during the process. A good jack pad will offer excellent weight distribution, preventing any damage to the vehicle’s undercarriage.

Advantages of BMW-Specific Jack Pads over Generic Ones

Generic jack pads may not be compatible with the intricate suspension systems and body designs of BMW models. This incompatibility can lead to uneven weight distribution and potential damage. BMW-specific jack pads, on the other hand, are designed to fit the precise contours of BMW chassis, ensuring safe and effective lifting. These tailored pads are optimized to support the specific weight distribution points of each model.

Comparison of BMW Jack Pad Materials

Different materials offer varying levels of performance and durability. Aluminum jack pads provide excellent strength and lightweight characteristics, while rubber or composite materials offer superior cushioning and shock absorption. However, the choice of material should consider the type of lifting and the potential for impact during the process.

- Aluminum: Aluminum jack pads are lightweight and strong, making them ideal for quick lifting and maintenance. However, they offer minimal cushioning, which could potentially cause damage to delicate undercarriage components if the surface is uneven.

- Rubber/Composite: Rubber or composite materials provide superior cushioning and shock absorption. This is beneficial for uneven surfaces and delicate undercarriages. However, they may not be as strong as aluminum and might be less resistant to repeated use.

Importance of Correct Jack Pad Size and Shape for BMW Models

The size and shape of a jack pad are crucial for ensuring safe and effective lifting. Incorrectly sized pads can cause uneven weight distribution, potentially leading to chassis damage. The specific size and shape are often determined by the location of the lifting point on the vehicle and the vehicle’s weight distribution.

Comparison of BMW Jack Pad Brands

| Brand | Material | Weight Capacity | Durability | Cushioning | Price |

|---|---|---|---|---|---|

| Brand A | Aluminum | 2000 lbs | High | Low | $25 |

| Brand B | Rubber Composite | 2500 lbs | Medium | High | $35 |

| Brand C | Steel | 3000 lbs | Very High | Medium | $45 |

Note: This table is a general comparison. Actual performance may vary depending on specific models and conditions.

Types and Selection of BMW Jack Pads

Choosing the right BMW jack pad is crucial for safe and effective vehicle maintenance. Improper jack pad selection can lead to damage to the vehicle’s undercarriage or even personal injury. Understanding the various types, sizes, and shapes of jack pads, along with their compatibility with specific BMW models, is essential for safe lifting and support.

BMW Jack Pad Types

Different types of BMW jack pads cater to specific needs and vehicle characteristics. These pads are designed to distribute weight evenly and protect the vehicle’s delicate undercarriage components from damage during lifting. Various materials and designs enhance their performance and safety.

- Standard Jack Pads: These pads are commonly used for basic lifting tasks and are typically made of rubber or composite materials. They provide a stable base for the jack and protect the vehicle’s paint and bodywork. Standard jack pads are suitable for routine maintenance like tire changes and minor repairs.

- Heavy-Duty Jack Pads: Designed for increased weight distribution, these pads are thicker and often feature reinforced construction. Heavy-duty jack pads are ideal for lifting heavier BMW models or when performing more extensive repairs that require significant weight support.

- Specialized Jack Pads: Certain BMW models may require specialized jack pads due to unique chassis designs or specific suspension components. These pads often feature tailored shapes or additional reinforcement to ensure safe lifting and support without causing damage to vulnerable areas.

- Universal Jack Pads: These pads are designed to accommodate a wider range of vehicle types, but their effectiveness may vary depending on the specific vehicle model. Universal pads are often a good choice for those who perform occasional maintenance or repairs on different vehicle types.

Factors for Choosing the Right Jack Pad

Several factors influence the selection of an appropriate BMW jack pad. Careful consideration of these factors ensures the safety of the vehicle and the technician.

- Vehicle Model and Year: Different BMW models have varying undercarriage designs and suspension systems. Consulting the vehicle’s repair manual or manufacturer’s specifications is essential to determine the correct jack pad size and type.

- Lifting Height and Weight: The jack pad’s size and material must adequately support the weight of the vehicle and the lifting height. For heavy-duty lifting, thicker and more robust pads are recommended.

- Lifting Point and Vehicle Design: The location of the lifting point on the vehicle and the overall vehicle design should be considered. Ensure the jack pad’s shape and size align with the intended lifting area to prevent damage and instability.

- Surface Condition: The surface on which the jack pad rests can impact the lifting process. A stable and flat surface is crucial for preventing the jack pad from slipping or shifting during lifting.

Jack Pad Sizes and Shapes

Jack pads come in various sizes and shapes to accommodate different vehicle models and lifting needs. The size and shape should be carefully chosen to ensure that the jack pad provides adequate support and stability.

- Sizes: Jack pad sizes are typically measured in inches or centimeters. A range of sizes is available to cater to different vehicle models and lifting requirements. The specific size should be chosen based on the vehicle’s weight and the lifting area.

- Shapes: Jack pad shapes can vary from rectangular to trapezoidal, depending on the design and placement needs. A jack pad’s shape should complement the vehicle’s undercarriage structure to avoid damage and ensure stable support.

Compatibility and Application

Ensuring compatibility between the jack pad and the specific BMW vehicle model is critical for safety. Incompatibility can lead to damage to the vehicle or injury. A table below illustrates the applications of different types of jack pads.

| Jack Pad Type | Application |

|---|---|

| Standard | Routine maintenance like tire changes, minor repairs |

| Heavy-Duty | Lifting heavier BMW models, extensive repairs |

| Specialized | Specific BMW models with unique chassis designs |

| Universal | Occasional maintenance on various vehicle types (use caution and check compatibility) |

Safety Precautions and Correct Usage

Proper use of BMW jack pads is crucial for ensuring the safety of both the user and the vehicle. Ignoring safety precautions can lead to accidents, damage to the vehicle, and even personal injury. This section Artikels essential safety precautions and correct procedures for installing and removing BMW jack pads, highlighting the potential risks of improper usage.

Careful attention to detail and adherence to the manufacturer’s instructions are paramount for a safe and successful lifting operation. Using the correct jack pads for the specific vehicle and surface is critical for preventing damage and accidents.

Safety Precautions When Using BMW Jack Pads

Adhering to safety precautions is essential to prevent accidents and ensure the safe use of BMW jack pads. This includes selecting the appropriate jack pad size and type for the vehicle and the surface where the vehicle is being lifted. Ensure the jack pad is positioned correctly to prevent slippage and maintain stability.

- Inspect the jack pad for any damage or defects. Cracks, tears, or other imperfections can compromise the pad’s structural integrity and lead to failure during lifting. Discard any damaged jack pads immediately. Regular inspections are essential for maintaining the integrity of the jack pad.

- Ensure the surface underneath the jack pad is stable and level. Uneven surfaces can cause the jack pad to shift or slip, leading to instability and potential accidents. Using a stable and level surface is critical for a safe lifting operation. Use additional support materials like jack stands if needed to enhance stability.

- Always consult the vehicle’s owner’s manual for specific instructions. The manufacturer’s instructions provide crucial guidance on the correct lifting points, appropriate jack pad sizes, and safe lifting procedures for the particular vehicle model. This step is paramount for maintaining vehicle safety and avoiding damage.

- Position the jack pad directly under the designated lifting point. Misplacing the jack pad can lead to uneven lifting, vehicle instability, and potential damage. Precise positioning of the jack pad is crucial for a safe lifting operation.

Proper Procedures for Installing and Removing BMW Jack Pads

Correct installation and removal procedures are vital for ensuring the safety of the vehicle and the user. Improper procedures can lead to damage and accidents.

- Before lifting the vehicle, ensure all passengers and objects have been removed. The presence of passengers or loose objects inside the vehicle can cause the vehicle to shift during lifting, posing a safety hazard. Emptying the vehicle before lifting is a critical safety precaution.

- Secure the vehicle using wheel chocks or other appropriate methods. This prevents the vehicle from rolling during the lifting process, ensuring the safety of the user and the vehicle. Utilizing wheel chocks or other stabilizing measures is critical for preventing accidents.

- Position the jack pad correctly under the designated lifting point. The jack pad should be positioned directly under the specified lifting point, ensuring a stable and even lifting surface. Correct placement is crucial for a safe lifting operation.

- Slowly raise the vehicle using the jack, ensuring the lifting point remains aligned with the jack pad. Sudden movements or uneven lifting can cause the vehicle to shift or tilt, potentially leading to accidents. Steady lifting is a key element in a safe lifting operation.

- Once the vehicle is lifted to the desired height, install the jack stands. This supports the weight of the vehicle and prevents the jack from collapsing, ensuring safety during any subsequent work. Installing jack stands is a crucial step in ensuring the vehicle’s stability and safety during maintenance work.

- Lower the vehicle slowly and carefully. Lowering the vehicle too quickly can cause the vehicle to shift or tilt, potentially leading to accidents. Careful and gradual lowering is critical for maintaining stability and preventing accidents.

- Remove the jack pads after the work is complete. Ensure the jack stands are removed before lowering the vehicle to the ground.

Potential Risks Associated with Incorrect Usage of BMW Jack Pads

Incorrect usage of BMW jack pads can lead to a variety of risks, ranging from minor damage to serious accidents.

- Vehicle damage. Improper lifting can cause structural damage to the vehicle, including frame damage, suspension damage, or component damage. Misaligned lifting points can result in vehicle damage.

- Personal injury. Vehicle movement or collapse can lead to serious injuries. Falls or collisions with moving parts can cause serious injuries to the user. Ensuring safety measures are in place is paramount.

- Damage to the jack pad. Using a jack pad on an unsuitable surface or in an inappropriate manner can lead to damage or failure of the jack pad, potentially resulting in accidents.

Importance of Securing the Vehicle Properly Before Lifting

Securing the vehicle properly is paramount for a safe lifting operation. This prevents the vehicle from moving or shifting during the lifting process, which could cause accidents.

| Safety Hazard | Mitigation Strategy |

|---|---|

| Vehicle movement | Use wheel chocks, parking brakes, or other appropriate securing methods. |

| Uneven lifting | Ensure the jack pad is positioned correctly under the designated lifting point. |

| Jack pad slippage | Use a stable and level surface for the jack pad. |

| Jack failure | Inspect the jack pad for damage and use only appropriate jack pads. |

Installation and Removal Procedures

Proper installation and removal of BMW jack pads are crucial for safe vehicle maintenance and avoiding damage. Incorrect procedures can lead to uneven lifting, potential structural issues, and personal injury. Following the detailed steps Artikeld below ensures the integrity of your vehicle and the safety of the mechanic.

Correct installation and removal of BMW jack pads are vital for safe vehicle maintenance. The procedures vary slightly based on the specific BMW model, engine placement, and the type of jack pad used. Understanding these differences is critical for effective and safe lifting and lowering.

Installation Procedures

Proper installation of BMW jack pads ensures even weight distribution and prevents damage to the vehicle’s undercarriage. A precise and secure placement is essential to maintain the vehicle’s structural integrity and safety during lifting and lowering.

- Assess the Vehicle’s Condition: Before starting, inspect the area under the vehicle for any debris, obstacles, or uneven surfaces that could compromise the lifting process. Ensure the chosen jacking points align with the vehicle’s structural design and the location of the jack pads.

- Select Appropriate Jack Pads: Choose jack pads that are compatible with the BMW model and the intended jacking point. Refer to the vehicle’s owner’s manual or a reputable source for specific recommendations.

- Position the Jack Pads: Place the jack pads directly under the designated jacking points. Ensure the pads are firmly in place and that the lifting surface is smooth and consistent. Avoid using jack pads that are damaged or worn.

- Engage the Jack: Carefully raise the vehicle using a suitable jack, ensuring the jack is positioned securely and the lifting points are consistent. The jack pads should remain stationary during the lifting process.

- Verify Stability: Once the vehicle is raised to the desired height, verify the stability of the vehicle. Check that the jacking points are firmly supported and that the vehicle is not swaying or shifting. Avoid excessive movement or instability.

Removal Procedures

Safe removal of BMW jack pads is equally important as their installation. The reverse order of installation is usually followed to avoid accidental drops or damage.

- Lower the Vehicle: Slowly lower the vehicle until the jack pads are no longer supporting the weight. Keep a watchful eye on the vehicle’s movement and stability.

- Remove the Jack Pads: Carefully remove the jack pads from the jacking points. Be sure to handle them with care to prevent damage or injury.

- Inspect the Area: After removing the jack pads, visually inspect the area under the vehicle for any damage or potential issues that may require further attention.

Model-Specific Considerations

Different BMW models may have variations in jacking points and recommended jack pad sizes.

| BMW Model | Typical Jacking Points | Specific Instructions |

|---|---|---|

| BMW 3 Series (2015-2020) | Front: Subframe, Rear: Rear Axle | Ensure jack pads are placed centrally under the designated points to prevent uneven lifting. |

| BMW X5 (2018-2023) | Front: Subframe, Rear: Rear Axle | Use wider jack pads for increased stability, especially when lifting the rear. |

| BMW M3 (2019-2024) | Front: Subframe, Rear: Rear Axle | Ensure the jack pads are positioned securely under the designated lifting points to prevent vehicle movement. |

Important Note: Always refer to your specific BMW owner’s manual for precise instructions and diagrams regarding jacking points and pad usage. The information provided here is a general guide.

Troubleshooting and Maintenance

Proper maintenance and troubleshooting of BMW jack pads are crucial for ensuring their longevity and preventing potential damage to your vehicle. Regular checks and timely repairs can save you significant time and expense in the long run. Addressing issues promptly can prevent more serious problems, like vehicle damage or injury.

Understanding common issues, their causes, and appropriate troubleshooting steps allows you to maintain the optimal performance and safety of your BMW jack pads. Following the recommended maintenance procedures will prolong their lifespan and guarantee their effectiveness during lifting operations.

Common Issues with BMW Jack Pads

BMW jack pads, like any mechanical component, can experience wear and tear. Identifying and addressing these issues proactively can prevent significant problems. Common issues can stem from improper use, environmental factors, or inherent material limitations.

Troubleshooting Steps for BMW Jack Pads

Troubleshooting BMW jack pads involves systematic checks and assessments. This process begins with visual inspection to identify any obvious signs of damage or wear.

- Visual Inspection: Carefully inspect the jack pad for cracks, deformation, or signs of excessive wear. Check for any loose or missing components. Look for any signs of corrosion, which can weaken the material and reduce the lifting capacity. Any abnormalities should be noted and addressed.

- Load Capacity Assessment: Ensure the load capacity of the jack pad is appropriate for the vehicle being lifted. Overloading can cause deformation or failure. Refer to the vehicle’s owner’s manual or the manufacturer’s specifications for accurate lifting capacities.

- Surface Assessment: Verify the surface beneath the jack pad is clean, level, and free of debris. Uneven surfaces can cause the jack pad to slip or shift, leading to potential damage. Make sure the area is clean and free from any sharp objects that could damage the jack pad.

- Jack Pad Material Condition: Evaluate the material of the jack pad for any signs of weakening. If the material is showing signs of deterioration, the jack pad should be replaced to prevent accidents.

Maintenance Procedures for BMW Jack Pads

Maintaining BMW jack pads is crucial for their continued performance and safety. Regular maintenance will help you prevent issues from arising in the future.

- Regular Cleaning: Clean the jack pads regularly to remove any dirt, debris, or other contaminants. This prevents the accumulation of corrosive materials that can compromise the jack pad’s structural integrity over time. Using a mild detergent and a soft cloth can effectively remove dirt and grime.

- Storage Considerations: Store jack pads in a dry, clean environment to protect them from moisture and environmental factors that can cause damage. Avoid storing them in direct sunlight or excessively humid areas.

- Periodic Inspection: Schedule periodic inspections to identify any potential problems early on. A visual inspection should be done every few months, or after significant use, to detect early signs of wear and tear.

Preventing Damage to BMW Jack Pads

Preventing damage to BMW jack pads is vital for their longevity. Following these guidelines will minimize the risk of compromising the integrity of the jack pad.

- Proper Lifting Techniques: Use the appropriate lifting techniques to prevent the jack pad from slipping or shifting during use. Ensure the jack pad is positioned correctly under the vehicle’s designated lifting points.

- Avoiding Sharp Objects: Ensure the surface underneath the jack pad is free from any sharp objects or debris that could damage the pad. Be aware of the area where you’re planning to lift your vehicle and clear it from any potential hazards.

- Correct Jack Pad Selection: Select the correct jack pad size and type for your vehicle’s lifting needs. Using the wrong jack pad can lead to improper lifting, potentially damaging both the jack pad and the vehicle.

Table of Common Problems and Solutions

| Problem | Solution |

|---|---|

| Cracks or deformation in the jack pad | Replace the jack pad immediately. |

| Jack pad slipping during lifting | Ensure the surface is level and free of debris. Verify the correct jack pad size for the vehicle. |

| Excessive wear on the jack pad | Replace the jack pad to prevent further damage. |

| Corrosion on the jack pad | Clean the jack pad with a mild detergent and soft cloth. If severe, consider replacement. |

Examples of BMW Jack Pad Applications

BMW jack pads are crucial for safe and effective car maintenance, particularly when working under the vehicle. Proper selection and application of these pads prevent damage to the vehicle’s undercarriage and ensure the safety of the technician. Choosing the right pad for the job is paramount to a successful and efficient repair.

Real-World Applications of BMW Jack Pads

BMW jack pads are essential for various maintenance tasks, from simple tire changes to complex engine repairs. Their diverse applications range from light-duty jobs to those requiring substantial support. Understanding the appropriate pad for each situation ensures the vehicle’s integrity and the technician’s safety.

Selecting the Appropriate BMW Jack Pad

The selection of the correct BMW jack pad depends on several factors, including the vehicle’s make, model, and the specific repair or maintenance task. Considering the load capacity, the type of surface the vehicle is resting on, and the specific area being worked on is crucial. Factors like the weight of the vehicle, the lifting point, and the support surface must be considered. The desired lifting height and the vehicle’s suspension characteristics are also critical elements to account for when selecting the correct jack pad. Furthermore, the type of material used in the jack pad can influence its performance and longevity. For instance, some pads are specifically designed for use on delicate paint jobs, while others are more robust and suitable for heavier lifting.

BMW Jack Pad Usage in Different Maintenance Scenarios

Different maintenance tasks require different jack pad types and sizes. The choice depends on the weight distribution of the vehicle, the lifting point, and the type of surface the car is resting on. A careful assessment of these factors is essential for selecting the appropriate pad.

| Maintenance Scenario | BMW Jack Pad Type | Rationale |

|---|---|---|

| Tire Change | Standard, low-profile pad | Relatively light lifting, even weight distribution on the pad. |

| Engine Replacement | Heavy-duty, multi-point pad | Significant weight distribution and potential for uneven lifting points. |

| Suspension Repair | Specialized, suspension-specific pad | Precision support and protection for suspension components. |

| Wheel Alignment | Precise, adjustable pad | Precise placement and support, often in alignment stands. |

| Brake Pad Replacement | Standard pad with additional support | Lifting the vehicle’s axle area, requiring adequate support. |

Alternatives and Comparisons

BMW jack pads offer a specific solution for lifting and supporting vehicles, particularly BMW models due to their unique suspension and body structures. However, other jacking methods exist, each with its own set of advantages and disadvantages. Understanding these alternatives allows for informed choices based on the specific task and vehicle type.

Alternative Jacking Methods

Various jacking methods exist beyond BMW jack pads, each with strengths and weaknesses. These include traditional floor jacks, bottle jacks, and ramps. Choosing the correct method hinges on the job’s requirements and the user’s experience and skill level.

Advantages and Disadvantages of Different Jacking Methods

- Traditional Floor Jacks: These are versatile and capable of lifting substantial weight. Their primary advantage is their robust construction and lifting capacity. However, they can be cumbersome to maneuver and require a flat, stable surface. Their size and weight also contribute to storage challenges.

- Bottle Jacks: Bottle jacks offer a compact and portable solution, making them ideal for tight spaces. They are generally lightweight and easy to store. However, their lifting capacity is often lower than floor jacks, and they can be more challenging to use for certain tasks requiring precision or extensive lifting.

- Ramps: Ramps are suitable for tasks involving minimal height adjustments. They provide a stable and safe lifting solution for tire changes and minor maintenance tasks. Ramps are easier on the vehicle’s suspension compared to jacks. However, they are less versatile for other repair jobs and often require more space than other methods.

Situations Favoring Alternatives

Several situations might make alternative jacking methods more appropriate than BMW jack pads. For example, if the task involves lifting a vehicle for engine replacement, a traditional floor jack with a higher lifting capacity would be more practical than a BMW jack pad designed for general maintenance. Similarly, a small repair shop might prefer ramps for routine tire changes due to their space-saving nature.

Applications Where Alternatives are More Suitable

- Heavy-duty repairs: For tasks requiring significant lifting capacity, such as engine replacements, traditional floor jacks are generally the preferred option over specialized jack pads.

- Tight spaces: In confined areas, bottle jacks’ portability and maneuverability make them more suitable than larger jack pads.

- Tire changes and basic maintenance: Ramps offer a safe and convenient solution for routine tire changes and other basic maintenance tasks, minimizing stress on the vehicle’s suspension.

Comparison Table of Jacking Solutions

| Feature | BMW Jack Pads | Floor Jacks | Bottle Jacks | Ramps |

|---|---|---|---|---|

| Lifting Capacity | Medium | High | Low to Medium | Low |

| Maneuverability | Good | Moderate | Excellent (tight spaces) | Excellent (minimal height) |

| Space Requirements | Moderate | High | Low | Moderate (for full lift) |

| Vehicle Compatibility | Specific to BMW | General-purpose | General-purpose | General-purpose |

| Safety | High, if used correctly | High, if used correctly | Moderate, if used correctly | High, if used correctly |

Deep Dive into Material Properties

BMW jack pads are crucial for safe and effective vehicle lifting. Understanding the materials used in their construction is vital for selecting the right pad for a specific application and ensuring long-term performance. Different materials offer varying levels of strength, durability, and resistance to wear and tear, directly impacting the safety and longevity of the lifting process.

Material selection in jack pads is heavily influenced by factors such as load-bearing capacity, surface hardness, and environmental resistance. This analysis delves into the properties of common materials, examining their strengths and weaknesses to provide a comprehensive understanding of their suitability for various BMW applications. The goal is to provide a clear comparison of material choices, facilitating informed decisions about jack pad selection.

Material Composition and Properties

The choice of material directly affects the jack pad’s performance, safety, and longevity. Common materials include steel, rubber, and plastic composites. Understanding their unique characteristics is essential for selecting the appropriate pad.

Steel

Steel jack pads are known for their high tensile strength and rigidity. They can withstand substantial loads, making them suitable for heavy-duty applications. However, steel’s hardness can lead to potential damage to the vehicle’s undercarriage if not used with caution. The high rigidity of steel can also cause a significant degree of stress concentration at the points of contact with the vehicle’s chassis. This stress concentration could lead to localized deformation or potential cracking over time.

Rubber

Rubber pads offer a cushioning effect, reducing the risk of scratching or damaging the vehicle’s undercarriage. Their flexibility makes them suitable for uneven surfaces and provides excellent vibration absorption. However, rubber’s flexibility also limits its load-bearing capacity compared to steel, and it can degrade over time due to exposure to UV radiation or extreme temperatures.

Plastic Composites

Plastic composites, often reinforced with fiberglass or other materials, provide a balance between strength and flexibility. These pads are lightweight, making them easier to handle. Their resistance to corrosion is also a significant advantage, extending their lifespan. However, plastic composites may not be as resistant to high loads or extreme temperatures as steel or rubber.

Environmental Impact

The environmental impact of jack pad materials should be considered. Steel production can contribute to greenhouse gas emissions and resource depletion. Rubber production can involve the use of chemicals and may lead to waste disposal issues. Plastic composites, depending on their composition, might also have environmental implications. Minimizing the environmental footprint of jack pad materials requires careful consideration of sourcing and manufacturing processes.

Summary Table

| Material | Strength | Flexibility | Durability | Load Capacity | Environmental Impact |

|---|---|---|---|---|---|

| Steel | High | Low | High | High | Medium |

| Rubber | Medium | High | Medium | Medium | Medium |

| Plastic Composite | Medium | Medium | Medium | Medium | Variable |