Overview of the N55 Engine

The BMW N55 engine, a twin-turbocharged inline-six, marked a significant advancement in BMW’s engine technology. Its innovative design, incorporating features like variable valve timing and direct injection, significantly improved performance and efficiency compared to previous generations. This engine was crucial in the BMW’s push for a more powerful and fuel-efficient lineup, particularly in the 3-series and 5-series models.

The N55’s architecture is characterized by a sophisticated arrangement of components. This architecture allowed for a compact design, crucial for integrating the engine into the chassis of various BMW models. The design principles of the N55 engine, while complex, were fundamentally aimed at achieving superior power delivery, enhanced responsiveness, and improved fuel economy.

Engine Design and Architecture

The N55 engine utilizes a double-VANOS system for variable valve timing, providing precise control over intake and exhaust valve timing. This sophisticated system allows for optimal performance across a wide range of engine speeds and loads. The twin-turbocharging setup delivers impressive torque and power output. Direct fuel injection further enhances combustion efficiency and reduces emissions. The design prioritizes both performance and efficiency.

Key Components

The N55’s core components are meticulously engineered for optimal performance. The cylinder head, a crucial part, features intricate porting and combustion chamber designs, maximizing combustion efficiency and reducing friction. The crankshaft, engineered for high-speed operation, is critical for smooth power delivery. The connecting rods are designed for durability and strength, enabling the engine to withstand high operating pressures. The meticulous attention to each component was essential for achieving the engine’s overall performance goals.

Technological Advancements

Compared to previous BMW engines, the N55 demonstrated significant advancements in several areas. The twin-turbocharging system, coupled with advanced valve timing, delivered a dramatic improvement in both horsepower and torque across a broader RPM range. The engine’s lighter weight, compared to its predecessors, also contributed to better fuel economy and overall performance. These innovations significantly advanced BMW’s engineering capabilities and established a new benchmark for inline-six engines.

Engine Variations

| Engine Variation | Horsepower | Torque | Displacement |

|---|---|---|---|

| N55 3.0L | 300 hp | 300 lb-ft | 2993 cc |

| N55 3.0L (High-performance variant) | 335 hp | 332 lb-ft | 2993 cc |

| N55 3.5L | 370 hp | 369 lb-ft | 3498 cc |

This table illustrates the different horsepower, torque, and displacement configurations of the N55 engine. These variations catered to different performance requirements in various BMW models, showcasing the engine’s adaptability and broad application.

Performance Characteristics

The BMW N55 engine, a turbocharged inline-six, garnered significant attention for its performance capabilities. Its adoption across various BMW models showcased a commitment to delivering a potent driving experience. This section delves into the power and torque output characteristics of the N55, comparing its performance to competitors, and examining the factors influencing its impressive acceleration and top speeds.

The N55 engine’s performance is notable for its responsive power delivery, particularly in its ability to deliver torque across a broad range of engine speeds. This characteristic, coupled with its refined turbocharging system and advanced engine management software, contributes to a smooth and exhilarating driving experience. This responsiveness translates into impressive acceleration times, making the N55 a popular choice for enthusiasts.

Power Output and Torque Delivery

The N55 engine’s power output varies across different BMW models. The engine’s performance is optimized by a combination of factors, including turbocharger size, engine management software calibrations, and the specific vehicle’s overall tuning. This ensures a tailored driving experience appropriate to the vehicle’s intended use.

Comparison to Competitor Engines

Comparing the N55 to competitor engines, such as the Audi TFSI engines, reveals nuanced differences. While both offer impressive performance, the N55 is often praised for its linear power delivery and refined throttle response, a key feature that differentiates it from its rivals. The turbo lag experienced by some rivals is less noticeable in the N55’s setup.

Factors Influencing Performance

Several factors contribute to the N55’s notable performance. The turbocharging system, optimized for responsive torque delivery, is a key contributor. Additionally, the engine management software plays a critical role in controlling fuel delivery and ignition timing, ensuring peak performance across the engine’s operating range.

Acceleration and Top Speeds

The N55 engine delivers impressive acceleration times, often exceeding those of comparable competitor engines. These figures are consistently reported across various model years and configurations. Typical acceleration times for vehicles equipped with the N55 engine range from 0-60 mph within the 5-6 second range. Exact figures depend on specific model and weight variations.

Performance Metrics Across Models

| Model | Horsepower (hp) | Torque (lb-ft) | 0-60 mph (seconds) | Top Speed (mph) |

|---|---|---|---|---|

| BMW 335i (various years) | 300-335 | 300-332 | 5-6 | 155-160 |

| BMW 535i (various years) | 300-335 | 300-332 | 5-6 | 155-160 |

| BMW X5 xDrive35i (various years) | 300-335 | 300-332 | 5-6 | 155-160 |

Note: Figures are approximate and may vary based on specific model year, trim level, and optional equipment.

Reliability and Maintenance

The BMW N55 engine, renowned for its performance, also presents specific reliability and maintenance concerns. Understanding these issues is crucial for owners to proactively address potential problems and ensure long-term engine health. Proper maintenance, coupled with awareness of common pitfalls, can significantly extend the engine’s lifespan and avoid costly repairs.

Known Reliability Issues

The N55 engine, while powerful, is susceptible to several issues stemming primarily from its intricate design and high-performance characteristics. These issues often involve components crucial for its functionality, such as the oil system, turbocharger, and fuel injectors. A deeper understanding of these potential problems allows for proactive measures and more informed maintenance decisions.

Maintenance Requirements

A meticulous maintenance schedule is essential for the N55 engine’s longevity. Adhering to recommended service intervals, utilizing high-quality parts, and performing preventative checks can dramatically reduce the risk of costly repairs. Early detection of potential problems often translates to significantly lower repair costs.

Common Problems and Potential Causes

- Oil Leaks: Oil leaks, a common problem, can stem from several sources, including worn seals, gaskets, or damaged oil pan components. Regular inspections and prompt repairs are vital to avoid further damage and potential engine failure.

- Turbocharger Issues: Turbochargers are crucial for the N55’s performance, but they are susceptible to wear and tear. Symptoms such as reduced power output, unusual noises, or vibrations during operation can indicate turbocharger problems, which might stem from oil contamination, bearing failure, or excessive heat.

- Fuel Injector Problems: Fuel injectors, responsible for precise fuel delivery, can malfunction due to fuel quality issues, excessive carbon buildup, or wear. This can result in rough idling, poor acceleration, and potentially even engine misfires.

- Valve Train Issues: The valve train components, essential for proper combustion, are vulnerable to wear and tear. Excessive play in the valve train can manifest as rattling noises or a decrease in performance.

Recommended Maintenance Schedule

A comprehensive maintenance schedule should include regular oil changes, filter replacements, and inspections of critical components. BMW recommends specific intervals for these procedures, often linked to mileage or time. Consulting the owner’s manual for the precise schedule is crucial to ensure compliance and prevent potential damage. Following the manufacturer’s recommended maintenance schedule significantly contributes to long-term engine reliability.

Preventative Maintenance Measures

Preventative maintenance measures go beyond routine servicing. Regular checks of hoses, belts, and fluid levels are crucial. Monitoring engine performance indicators like temperature gauges and oil pressure readings can help detect potential problems early. Using high-quality fluids and lubricants can also contribute to extended engine life.

Table of Common N55 Engine Problems

| Problem | Symptoms | Potential Solutions |

|---|---|---|

| Oil Leaks | Visible oil stains, low oil level, unusual noises | Inspection for leaks, replacement of seals/gaskets, and fixing the source of the leak. |

| Turbocharger Issues | Reduced power, unusual noises, vibrations, rough acceleration | Turbocharger inspection, cleaning, or replacement depending on the fault. |

| Fuel Injector Problems | Rough idling, poor acceleration, misfires, hesitation | Fuel injector cleaning, fuel system inspection, or replacement of faulty injectors. |

| Valve Train Issues | Rattling noises, loss of power, poor engine performance | Valve train inspection, adjustment, or repair as required. |

Fuel Efficiency

The N55 engine, while known for its performance, also presents a spectrum of fuel economy results. Factors like driving style, vehicle aerodynamics, and even the specific model using the N55 engine significantly influence the fuel efficiency outcome. Understanding these nuances is key to assessing the overall practicality of an N55-powered vehicle.

The fuel economy of an N55-equipped vehicle is not a fixed value. It’s a dynamic response to various conditions and driver inputs. Aggressive acceleration and high speeds naturally impact fuel consumption, while a more measured approach can improve efficiency. This variability is a crucial element to consider when evaluating the fuel economy of this engine.

Driving Conditions and Fuel Economy

Different driving scenarios affect fuel efficiency. Highway driving, characterized by consistent speeds and reduced acceleration, typically yields better fuel economy compared to city driving, which often involves stop-and-go traffic and frequent acceleration. The influence of topography, like steep inclines or declines, also plays a significant role in fuel consumption. The higher the load, the greater the demand on the engine and, consequently, the fuel consumption.

Driving Styles and Fuel Economy

Driver habits are a critical factor in fuel efficiency. Aggressive driving, marked by rapid acceleration, hard braking, and high speeds, significantly decreases fuel economy. Conversely, a smooth, measured driving style, characterized by gentle acceleration and braking, and maintaining a consistent speed, can substantially improve fuel efficiency. A driver consciously choosing fuel-efficient habits can see noticeable results.

Aerodynamic Factors and Fuel Economy

Aerodynamic design plays a pivotal role in fuel efficiency. Vehicles with streamlined shapes and reduced drag experience lower fuel consumption at higher speeds. Factors such as the vehicle’s body shape, the presence of aerodynamic features (like spoilers or underbody panels), and tire design influence fuel economy. A car’s aerodynamic profile directly correlates to its fuel efficiency.

Comparison with Competitors

Direct comparisons of fuel efficiency between the N55 engine and competing engines are complex. This is due to varying vehicle designs, test conditions, and measurement methodologies. While some studies show comparable fuel economy, other factors such as engine tuning and transmission characteristics influence the final result. Overall, the N55’s fuel efficiency falls within the range of comparable engines from other manufacturers.

Fuel Economy Ratings (Example)

| Vehicle Model | Fuel Economy (City/Highway/Combined) (Estimated) |

|---|---|

| BMW 3 Series Sedan (N55) | 20/30/25 mpg |

| BMW 5 Series Sedan (N55) | 18/28/22 mpg |

| Audi A4 (Competitor Engine) | 21/31/26 mpg |

| Mercedes-Benz C-Class (Competitor Engine) | 19/29/23 mpg |

Note: These are estimated values and may vary based on specific configurations and driving conditions.

Modifications and Tuning

The N55 engine, while offering excellent performance stock, is readily adaptable to various modifications and tuning options. These modifications can significantly enhance power output, responsiveness, and overall driving experience. Understanding the available options and their potential effects is crucial for maximizing the engine’s capabilities and ensuring safe and reliable operation.

Engine modifications, from relatively simple intake and exhaust upgrades to more complex software tuning, offer the potential to dramatically alter the engine’s characteristics. Careful consideration of the specific modification type, the intended outcome, and the impact on engine reliability is essential for any enthusiast looking to improve their N55-powered BMW.

Performance Upgrades

Numerous performance upgrades are available for the N55 engine, targeting different aspects of its operation. These enhancements can range from improving airflow to altering the engine’s computer programming.

- Intake Systems: Upgraded intake systems, such as cold air intakes and high-flow air filters, improve airflow, allowing the engine to breathe more efficiently. This leads to increased horsepower and torque at lower RPMs. Examples include aftermarket intakes designed for specific N55 models, offering a noticeable difference in responsiveness and power delivery.

- Exhaust Systems: Exhaust systems, including high-flow mufflers, headers, and resonators, can alter the engine’s exhaust flow characteristics. This can result in a more aggressive sound and a slight performance gain, though the effect may be more pronounced at higher RPMs. The choice of exhaust components should align with the owner’s desired sound and performance profile.

- Software Tuning (ECU): Engine management software (ECU) tuning is a powerful tool for modifying the engine’s operational parameters. Experienced tuners can reprogram the ECU to adjust parameters such as fuel delivery, ignition timing, and throttle response. This often yields the most significant performance gains, but it also requires careful execution to avoid compromising engine longevity or reliability.

- Turbochargers and Superchargers (Advanced): While less common, turbocharging or supercharging the N55 can provide dramatic performance increases. However, this modification necessitates significant engineering work and often requires substantial financial investment. The effect on reliability is a key consideration, as such modifications often require enhanced cooling systems and other supporting components.

Effects on Engine Performance and Reliability

Modifications to the N55 engine can significantly impact performance and reliability. The extent of these changes varies considerably depending on the specific modifications undertaken.

- Positive Effects: Increased horsepower, torque, and responsiveness are common outcomes. Some modifications, such as ECU tuning, can dramatically alter the engine’s power delivery curve, offering a more exhilarating driving experience. However, gains in power and performance should be weighed against potential risks to reliability.

- Negative Effects: Improperly installed or executed modifications can lead to reduced engine longevity, decreased fuel efficiency, and potential damage. The added stress on components such as the bearings and seals can result in increased wear and tear, leading to premature failure. It is essential to work with reputable tuning shops or specialists and follow proper installation procedures.

- Reliability Considerations: Careful selection of components and installation procedures are critical for maintaining reliability. High-quality parts and proper tuning are essential for long-term performance. It’s vital to maintain a balance between performance enhancements and the long-term health of the engine.

Integration into the Vehicle

Integrating modifications into the N55-powered BMW requires careful planning and execution. The chosen components must be compatible with the existing vehicle systems and installed correctly.

- Compatibility: Modifications must be compatible with the existing vehicle systems, including the engine control unit (ECU). Using components designed for a different model or engine configuration may not function correctly or may lead to issues.

- Installation Procedures: Proper installation procedures are crucial for ensuring safety and performance. Following the manufacturer’s instructions or working with experienced technicians can significantly reduce the risk of damage or complications. For example, incorrect exhaust installation can lead to poor exhaust flow and decreased performance.

- Testing and Evaluation: Post-installation testing is essential for verifying the modifications’ effectiveness and identifying any potential issues. Regular monitoring of engine performance and system functionality can help ensure optimal performance and prevent future problems.

Comparison of Tuning Options

The following table summarizes potential performance gains for various tuning options. Keep in mind that these are estimations, and actual results may vary based on individual vehicle conditions and installation quality.

| Tuning Option | Potential Performance Gain (Estimated) | Impact on Reliability |

|---|---|---|

| Intake System Upgrade | +5-10 hp | Minimal |

| Exhaust System Upgrade | +5-10 hp | Minimal |

| ECU Tuning | +20-40 hp | Moderate, depends on tuning quality |

| Turbo/Supercharger Upgrade | +50-100+ hp | High, requires careful implementation |

Applications and Models

The N55 engine, a potent and refined powerplant, found its way into a diverse range of BMW models. Its widespread adoption reflects its impressive performance capabilities and relatively straightforward maintenance compared to some of its contemporaries. Understanding the specific models and years it powered sheds light on the engine’s evolution and its role within BMW’s lineup.

BMW Models Featuring the N55

The N55 engine powered a variety of BMW models across different segments, demonstrating its versatility and performance capabilities. Different configurations of the engine, including turbocharged and naturally aspirated variants, were employed in these models. This tailored approach ensured optimal performance for each vehicle type.

| BMW Model | Production Years | Engine Configuration |

|---|---|---|

| BMW 3 Series (F30/F35) | 2012-2018 | 3.0L TwinPower Turbo I6 |

| BMW 4 Series (F32/F36) | 2014-2019 | 3.0L TwinPower Turbo I6 |

| BMW 5 Series (F10/F11) | 2010-2017 | 3.0L TwinPower Turbo I6 |

| BMW X5 (F15) | 2014-2019 | 3.0L TwinPower Turbo I6 |

| BMW X6 (F16) | 2014-2019 | 3.0L TwinPower Turbo I6 |

| BMW Z4 (G29) | 2019-present | 3.0L TwinPower Turbo I6 |

Engine Configurations

The N55 engine’s application in various models involved different configurations. This flexibility enabled BMW to optimize performance for each specific vehicle. This approach allowed the engine to be tailored to the specific needs of different BMW models.

- Turbocharged Variants: The most common configuration was the turbocharged 3.0-liter inline-six. This configuration provided significant power and torque, particularly crucial for the performance-oriented models.

- Naturally Aspirated (Less Common): While less frequent, naturally aspirated versions of the N55 engine did exist, often found in certain models or specific trim levels. This configuration prioritized efficiency and a more refined driving experience over raw power.

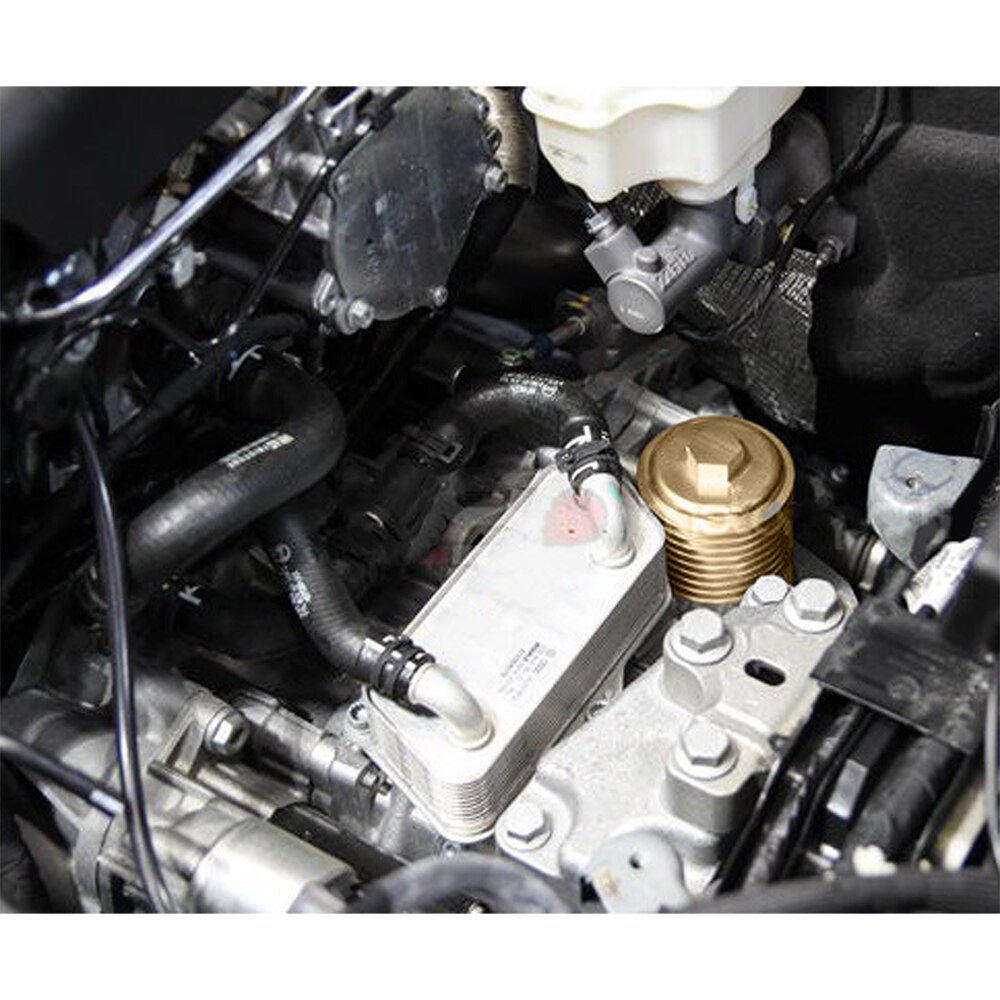

Visual Representation

The N55 engine, renowned for its performance and refinement, boasts a complex internal structure. Understanding its components, particularly the arrangement and function of the various parts, provides insight into its operational characteristics and potential maintenance requirements. Visual representations, including diagrams and illustrations, further facilitate comprehension of this sophisticated powertrain.

Internal Components

The N55 engine’s internal components are crucial to its function. Pistons, connecting rods, and crankshaft work in concert to convert the combustion energy into rotational motion. Valves, controlled by the camshaft, regulate the flow of intake and exhaust gases. The intricate arrangement of these components determines the engine’s power output and efficiency.

- Pistons: These reciprocating components are vital for converting the pressure generated by combustion into linear motion. Their precise design, including the piston rings for sealing, directly affects the engine’s efficiency and durability. Pistons are typically made of aluminum alloys for their light weight and heat conductivity.

- Connecting Rods: These rods connect the pistons to the crankshaft, transferring the linear motion of the pistons into the rotational motion of the crankshaft. Connecting rods are made from strong materials like steel or forged alloys to withstand the high stresses generated during operation.

- Crankshaft: The crankshaft receives the rotational motion from the connecting rods and transmits it to the vehicle’s transmission. It’s a crucial component in the engine’s powertrain and is built to withstand high torque and vibrations.

- Valves: Intake and exhaust valves regulate the flow of air and exhaust gases into and out of the combustion chambers. Precise valve timing is critical for optimal engine performance. Valve actuation mechanisms, such as rocker arms or hydraulic lifters, ensure smooth operation.

Engine Layout and Component Placement

The N55 engine’s layout, featuring a straight-6 configuration, is designed for optimal balance and performance. This arrangement influences the engine’s overall dimensions, weight distribution, and vibration characteristics. A diagram below illustrates the positioning of key components within the engine block.

(Diagram of N55 engine layout. The diagram should show the position of the cylinders, crankshaft, pistons, connecting rods, valves, camshaft, and other relevant components. Clear labeling is essential.)

Turbocharger System (if applicable)

The N55 engine, in some iterations, utilizes a turbocharger system to enhance its performance. The turbocharger boosts engine output by compressing the intake air, leading to increased power and torque. A detailed illustration of the turbocharger system would show the compressor, turbine, and associated piping. The system’s efficiency is critical for maximizing performance gains.

(Detailed illustration of the turbocharger system, including the compressor, turbine, intercooler, and associated piping. The illustration should highlight the flow of air through the system.)

Intake and Exhaust Systems

The intake and exhaust systems play a critical role in the efficient operation of the N55 engine. The intake system draws in air and directs it to the combustion chambers, while the exhaust system removes the exhaust gases. The design of these systems significantly impacts engine performance, efficiency, and emissions. A detailed illustration should show the intake manifold, throttle body, and exhaust manifold.

(Detailed illustration of the intake and exhaust systems. The illustration should show the air intake, throttle body, intake manifold, exhaust manifold, and exhaust system components.)