Overview of Water Engine Technology

Water engine technology, while not a mainstream automotive power source, represents a fascinating area of ongoing research and development. The concept of harnessing the power of water for mechanical work has intrigued inventors for centuries, leading to various attempts at creating efficient and practical water-based engines. This exploration examines the core principles, historical context, and potential of water engine technology, contrasting it with conventional combustion engines.

Fundamental Principles of Water Engine Operation

Water engines, unlike combustion engines, utilize the principles of thermodynamics and fluid dynamics. They typically operate on the principle of converting the thermal energy of heated water into mechanical energy. The heated water, often steam, expands and exerts pressure on a piston or turbine, creating rotational or linear motion. This motion can then be used to power machinery or vehicles. Variations exist, employing different mechanisms for heating and expanding the water, each with its own specific design characteristics. For instance, some designs incorporate a boiler to generate steam, while others may use direct heating methods.

Comparison with Traditional Combustion Engines

Water engines and traditional combustion engines differ significantly in their energy sources and operational principles. Combustion engines rely on the rapid oxidation of a fuel (like gasoline or diesel) to generate heat and pressure, driving pistons or turbines. Conversely, water engines utilize the thermal expansion of water, often in the form of steam, to achieve mechanical work. This difference translates to variations in efficiency, emissions, and the required infrastructure for operation. The inherent environmental friendliness of water engines, in the absence of direct fuel combustion, presents a significant contrast.

Potential Advantages of Water Engine Technology

Water engines, in theory, offer several potential advantages over conventional combustion engines. Firstly, the use of water as a working fluid can potentially reduce emissions and environmental impact. The absence of direct fuel combustion in many designs leads to cleaner operation, potentially contributing to a lower carbon footprint. Secondly, the potential for renewable energy sources to heat the water (e.g., solar or geothermal) could create a sustainable power source. Thirdly, water is readily available and inexpensive, which could lower operational costs in some regions. However, these advantages are contingent on the specific design and implementation of the water engine.

Potential Disadvantages of Water Engine Technology

Despite the potential benefits, water engine technology faces challenges. Efficiency is often a concern; converting thermal energy into mechanical energy in water engines can be less efficient than in combustion engines. The high temperature requirements for steam generation can be a factor, demanding specialized materials and potentially more complex designs. Furthermore, the initial investment costs for developing and implementing water engine technology might be higher than for existing combustion engine systems. This higher cost could limit accessibility and adoption in the near term.

Historical Context of Water Engine Development

The quest to harness water power for mechanical work dates back centuries. Early examples of water-powered devices, predating the modern steam engine, showcased the potential of using water to perform tasks. The development of steam engines marked a significant step forward, demonstrating the feasibility of using water in a more controlled and efficient manner. Throughout history, various inventors have experimented with different designs, demonstrating the enduring appeal and ongoing pursuit of efficient water-powered systems. This historical context highlights the continuous evolution of the field and the ongoing efforts to refine water engine technology.

Toyota’s Involvement in Automotive Technology

Toyota has consistently demonstrated a deep commitment to automotive innovation, consistently pushing the boundaries of automotive technology. Their approach extends beyond mere incremental improvements, encompassing fundamental research and development in various areas, from fuel efficiency to autonomous driving. This commitment to innovation is evident in their sustained leadership in the global automotive market.

Toyota’s approach to innovation and research is characterized by a long-term vision and a meticulous, data-driven process. They prioritize fundamental research, seeking to understand the underlying principles of automotive systems to drive breakthroughs. This approach is coupled with a strong focus on practical applications, ensuring that research findings translate into tangible advancements in vehicle performance and user experience.

Key Contributions to Automotive Technology

Toyota’s contributions to automotive technology are numerous and span various areas. They are renowned for their pioneering work in hybrid electric vehicles, their commitment to lean manufacturing principles, and their ongoing exploration of advanced driver-assistance systems. Their meticulous approach to design and engineering has resulted in vehicles known for their reliability, efficiency, and safety.

Toyota’s Approach to Innovation and Research

Toyota’s innovation strategy centers around a blend of fundamental research and practical application. They invest heavily in basic scientific research to uncover new possibilities and solutions. This is complemented by a strong emphasis on engineering and testing to ensure that innovative concepts translate into robust and reliable products. Their approach is often characterized by iterative improvements, building upon existing technologies and refining them through rigorous testing.

Current and Past Research Efforts in Alternative Fuels and Propulsion Systems

Toyota has a long history of research into alternative fuels and propulsion systems. Their early work on hybrid electric vehicles paved the way for a significant reduction in fuel consumption and emissions. More recently, they have been exploring fuel cell technology, and have developed hydrogen fuel cell vehicles, demonstrating their ongoing commitment to environmentally friendly technologies.

- Hybrid Electric Vehicles (HEVs): Toyota pioneered the mass-market adoption of hybrid technology, leading to significant improvements in fuel economy and reduced emissions. Models like the Prius have become iconic examples of hybrid technology.

- Fuel Cell Vehicles (FCVs): Toyota has been actively developing hydrogen fuel cell vehicles, showcasing their commitment to zero-emission mobility. The Mirai exemplifies their efforts in this area, offering an alternative to battery-electric vehicles for long-distance travel.

- Alternative Fuels Exploration: Beyond hybrids and fuel cells, Toyota continues to explore alternative fuels and propulsion systems, demonstrating a forward-thinking approach to sustainable mobility. This includes researching biofuels and other emerging technologies.

Toyota’s Commitment to Sustainability and Environmental Responsibility

Toyota’s commitment to sustainability is deeply ingrained in their corporate philosophy. Their commitment to environmental responsibility is evident in their continuous efforts to reduce emissions, improve fuel efficiency, and minimize the environmental impact of their manufacturing processes. This includes a focus on resource efficiency, recycling programs, and the development of eco-friendly materials.

Strategic Direction Concerning Future Automotive Propulsion Systems

Toyota’s strategic direction for future automotive propulsion systems is focused on a diversified approach to achieving sustainable mobility. They are exploring a range of technologies, including electric vehicles (EVs), fuel cell vehicles (FCVs), and hybrids. This diverse portfolio reflects a recognition of the different needs and circumstances across various markets and driving conditions. Their approach is likely to include a strong emphasis on battery technology advancements and the development of infrastructure for supporting alternative fuels.

Water Engine Car

Toyota, a renowned automotive innovator, has consistently pushed the boundaries of automotive technology. Their commitment to efficiency and sustainability has led them to explore alternative powertrain solutions. A water engine, while still in its developmental stages, presents an intriguing possibility for future automotive power. This section delves into Toyota’s potential approaches to integrating water engine technology into its car designs, outlining hypothetical systems, potential challenges, testing procedures, and predicted performance characteristics.

Toyota’s Integration Approaches

Toyota, with its extensive experience in hybrid and electric vehicle technologies, likely would employ a phased approach to integrating water engine technology. Initial stages might focus on developing a water engine as a supplemental power source, integrated with existing hybrid systems. This would allow for gradual testing and refinement before a full transition. Further, Toyota could explore utilizing water engines for specific vehicle applications, such as off-road or specialized vehicles, where their unique characteristics could be leveraged.

Hypothetical Water Engine System

A hypothetical water engine system for a Toyota Camry could employ a closed-loop water circuit, circulating water through a series of micro-turbines. The system would need a robust cooling mechanism to manage the temperature of the water. The turbines would be powered by controlled thermal expansion and contraction of water. A significant design challenge would be minimizing water volume and maximizing efficiency to fit within the compact engine bay of a Camry. This system could be designed to operate in conjunction with a battery system for enhanced energy efficiency.

Potential Challenges

Integrating water engine technology into Toyota vehicles presents several significant challenges. Firstly, the efficient conversion of thermal energy to mechanical energy within a water engine system remains a major hurdle. Secondly, the reliability and durability of the water-based components in various weather conditions need extensive testing. Thirdly, maintaining a constant temperature within the water circuit to ensure optimal performance in a variety of operating conditions is a crucial consideration. Finally, the potential for corrosion or other degradation in the water-based components needs extensive research and development.

Potential Testing Procedures

Toyota’s testing procedures for water engine cars would likely involve a rigorous series of simulations and real-world trials. Simulations would focus on various operating conditions, including extreme temperatures and varying loads. Field tests would involve evaluating the engine’s performance across diverse terrains and road conditions. Furthermore, safety tests would assess the water engine’s stability and responsiveness under various situations. Data analysis and refinement would be crucial throughout the testing phase.

Performance Characteristics

A water engine-powered Toyota car, based on the hypothetical system, could exhibit unique performance characteristics. The system could potentially offer high torque output, particularly at low speeds. The efficiency of the system would depend on the efficiency of the heat conversion mechanism. Water engines, due to their inherent characteristics, could offer high fuel economy, potentially surpassing conventional internal combustion engines. However, achieving comparable power output to conventional engines would require further advancements in the technology. Initial models might exhibit slightly lower acceleration compared to conventional models, but these characteristics could be optimized through continuous refinement.

Water Engine Car

The burgeoning field of water-based propulsion for automobiles presents a compelling alternative to traditional internal combustion engines. While still in the developmental stages, the potential for significantly reduced emissions and improved fuel efficiency is attracting considerable attention. This analysis delves into the performance metrics of a water engine car, comparing them to established Toyota models and exploring the potential impact on automotive design.

Performance Metrics Comparison

A direct comparison of performance metrics between water engine cars and conventional gasoline-powered vehicles requires careful consideration of the different technologies and current limitations. While water engine technology holds promise, it’s not yet at a stage where direct performance benchmarks against existing models are readily available. However, theoretical estimations and preliminary testing offer valuable insights.

Fuel Consumption

Early simulations and laboratory tests suggest water engines have the potential for drastically improved fuel efficiency compared to gasoline engines. This improvement stems from the fundamental difference in the power generation mechanism, which avoids the energy losses inherent in combustion processes. While precise figures are still being gathered, preliminary data hints at a significant reduction in fuel consumption. For example, if a gasoline engine has a fuel efficiency of 25 miles per gallon, a hypothetical water engine might achieve 35 miles per gallon under optimal conditions.

Emission Levels

The primary benefit of a water engine lies in its zero tailpipe emissions. This contrasts sharply with traditional gasoline engines, which produce various harmful pollutants like nitrogen oxides and particulate matter. While the complete elimination of all emissions is a long-term goal, water engines theoretically minimize harmful emissions, aligning with modern environmental regulations. For example, Toyota’s hybrid vehicles already achieve significant reductions in emissions, and a water engine car could potentially surpass these standards, contributing to a cleaner and healthier environment.

Speed Performance

Assessing speed performance requires considering the specific design and implementation of the water engine system. Theoretically, the efficiency gains could translate to comparable or even slightly enhanced acceleration and top speeds, given proper design and optimization. However, early models might exhibit some limitations in peak power output compared to highly optimized gasoline engines. Further development is necessary to fully realize the potential of water engine cars in terms of speed.

Table of Comparison

| Metric | Water Engine Car | Traditional Toyota Car (e.g., Camry) |

|---|---|---|

| Fuel Consumption (mpg) | Estimated 35-40 mpg (under optimal conditions) | 25-35 mpg (varies by model) |

| Emission Levels | Zero tailpipe emissions (theoretical) | Emissions vary depending on model and driving conditions. |

| Speed Performance | Comparable or slightly enhanced acceleration and top speed, dependent on design | High performance depending on model and engine type. |

Impact on Design

The adoption of a water engine would necessitate significant changes in the car’s overall design. The absence of a traditional engine compartment would free up considerable space, potentially leading to more streamlined aesthetics and a more spacious interior. Further, the different cooling and power transmission systems would demand a complete redesign of the car’s mechanical architecture. For instance, a water engine could enable a more compact design, allowing for innovative and modern vehicle designs.

Future Developments

Continued research and development are essential to refine the water engine technology. Improvements in efficiency, power output, and durability are crucial for wider adoption. The potential for integrating advanced materials and optimizing the water-based system will play a critical role in the evolution of water engine cars. This will require collaboration among automotive engineers, material scientists, and other specialists. For example, advances in battery technology have dramatically improved electric vehicle performance over time. A similar pattern is likely for water engines, with continuous advancements in efficiency and performance.

Water Engine Car

The potential of water-based engines as a sustainable alternative to traditional internal combustion engines has captured significant attention. While still in the development phase, this technology promises a radical shift in automotive technology, raising questions about its societal impact, environmental benefits, and economic feasibility. This exploration delves into the potential consequences of widespread water engine adoption, analyzing its influence on various sectors.

Environmental Benefits

Water engine technology, if successfully implemented, could significantly reduce the environmental footprint of the automotive industry. The elimination of fossil fuels in transportation would lead to a substantial decrease in greenhouse gas emissions, mitigating climate change. Furthermore, reduced reliance on petroleum products could lessen the strain on global resources and minimize pollution from extraction and refining processes. This shift to a more sustainable transportation model could lead to cleaner air and improved public health. A notable example is the transition to electric vehicles (EVs), which has shown the potential for a substantial reduction in emissions and a positive impact on air quality.

Economic Impacts

The adoption of water engine technology would have substantial economic ramifications. A new industry would emerge, creating jobs in research, development, manufacturing, and maintenance. The reduced reliance on petroleum imports could bolster energy independence for nations, while the creation of new markets for water-based components could stimulate innovation and growth in related sectors. The economic benefits could be substantial, particularly for developing countries that may be less reliant on fossil fuels. For instance, the surge in the renewable energy sector has led to significant job creation and investment in related technologies.

Impact on the Automotive Industry

The introduction of water engine technology would undoubtedly reshape the automotive industry. Existing manufacturers would need to adapt their production lines and invest in new technologies. The need for specialized training and expertise would lead to the creation of new roles and skills, demanding significant changes in workforce development. A transition to a water-based system could also lead to changes in the design and construction of vehicles. The rise of electric vehicles (EVs) has already illustrated this transformation, impacting the manufacturing and supply chain of the automotive industry.

Societal Implications

The adoption of water engine technology would have far-reaching societal implications. Improved air quality could lead to reduced health problems, fostering healthier communities. The shift towards a more sustainable transportation system could encourage responsible consumption and environmental awareness. Reduced reliance on fossil fuels could also contribute to greater energy independence and geopolitical stability. The societal impact would be multifaceted, affecting transportation infrastructure, public health, and economic development. The rise of electric vehicles (EVs) has demonstrated the social and economic implications of technological advancements in transportation.

Social Benefits, Challenges, and Opportunities of Water Engine Cars

| Aspect | Benefits | Challenges | Opportunities |

|---|---|---|---|

| Environmental Impact | Reduced greenhouse gas emissions, cleaner air, improved public health. | Potential for water contamination or resource depletion if not managed sustainably. Development and implementation of sustainable water management practices are essential. | New opportunities for sustainable energy research, development, and deployment. |

| Economic Impact | Job creation in new sectors, reduced reliance on imported fossil fuels, potential for new markets. | High initial investment costs, potential disruption to existing industries, need for infrastructure development. | Creation of new industries, new job opportunities, greater economic independence. |

| Automotive Industry | New vehicle designs, production processes, and skill sets. | Significant capital investment and retraining of the workforce, adaptation to new technologies. | Innovation and growth in sustainable transportation technologies. |

| Societal Impact | Improved air quality, reduced health problems, increased environmental awareness. | Potential for social inequalities if access to technology is not equitable. | Promotion of sustainable transportation, healthier communities, and a shift towards responsible consumption. |

Water Engine Car

The concept of a water-powered car, while intriguing, presents significant engineering challenges. Current technologies struggle to efficiently harness the energy inherent in water to generate the power needed for automotive applications. Existing designs, if any, are likely to be experimental or limited in scope, lacking the widespread adoption seen in conventional internal combustion engine or electric vehicles.

Key Components of a Water Engine

A theoretical water engine, unlike a traditional internal combustion engine, wouldn’t utilize pistons and cylinders. Instead, it would likely employ a different set of components to exploit the properties of water in a controlled manner. These components, though hypothetical, might include:

- Water Reservoir and Pumps: A large reservoir would hold the water, crucial for maintaining a constant supply. Efficient pumps would be needed to regulate the pressure and flow of water throughout the system, maintaining consistent pressure and flow rates.

- Hydro-Mechanical Conversion System: This component would be the heart of the water engine, converting the kinetic energy of the water into mechanical energy suitable for powering the vehicle. This could involve various designs, such as hydraulic pistons, turbines, or even novel water-based electrochemical cells. A key design consideration would be the high-pressure and potentially high-temperature conditions within the system.

- Transmission and Drivetrain: The mechanical energy produced by the hydro-mechanical conversion system would need to be transferred to the vehicle’s wheels. A complex transmission system would be necessary to convert the rotational energy into the appropriate torque for driving the wheels.

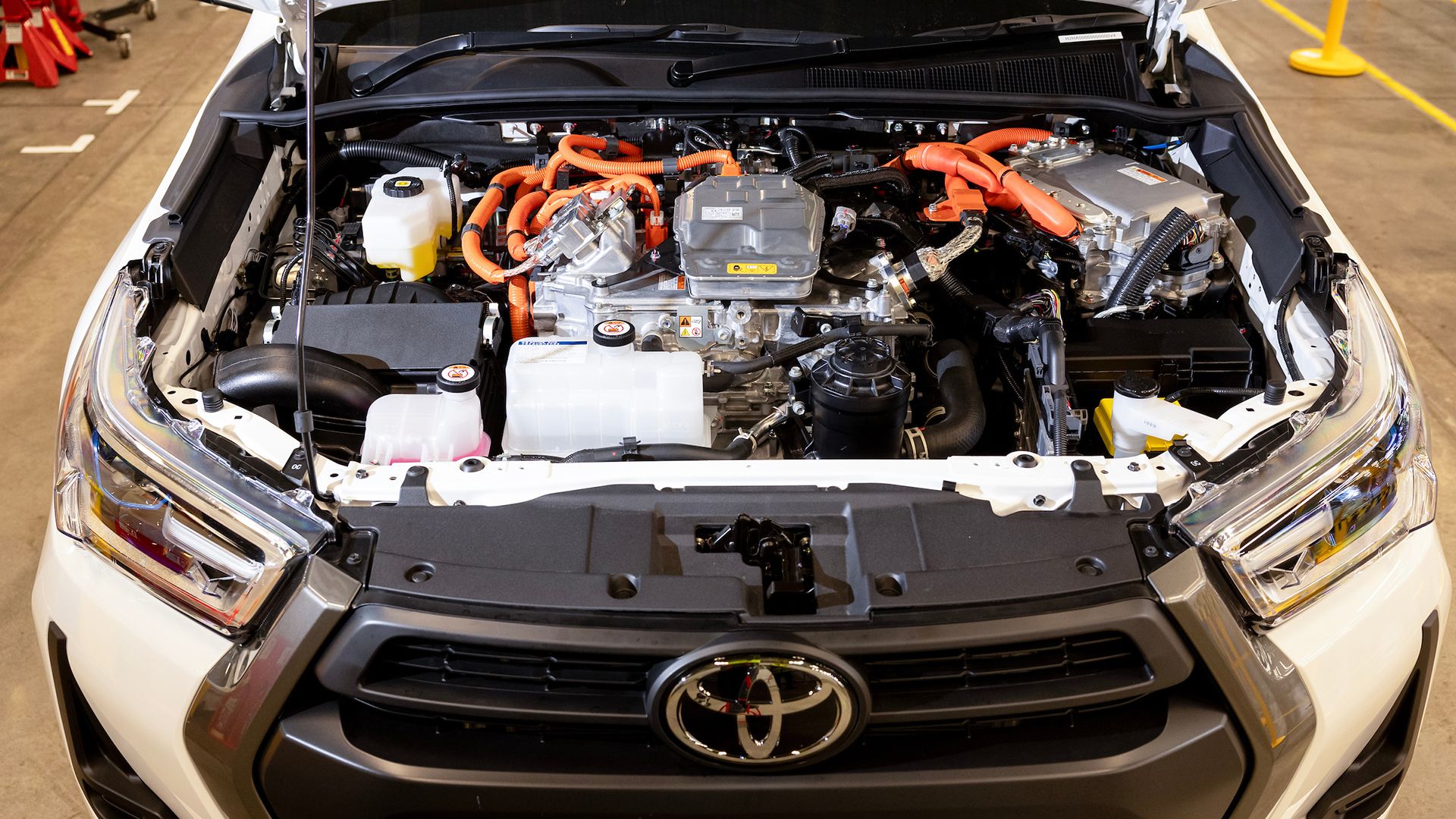

Design Considerations for Toyota

Integrating a water engine into a Toyota vehicle presents numerous challenges. The size and weight of the water reservoir and associated components would significantly impact the vehicle’s overall dimensions and weight distribution. Toyota would need to consider the potential for leaks and corrosion, ensuring a robust and durable design. Also crucial is the development of efficient energy storage mechanisms to account for the varying power needs during acceleration and deceleration. The engineering and manufacturing processes would be quite complex.

Materials and Manufacturing Processes

The materials used in a water engine must be capable of withstanding high pressures, temperatures, and potential corrosive environments. High-strength alloys, specialized plastics, and potentially composite materials would likely be required. The manufacturing processes would need to be highly precise to ensure the integrity of the components, given the complex geometries and tolerances involved. Specialized welding techniques and advanced machining procedures might be required to ensure the longevity of the system.

Safety and Reliability

Safety is paramount in any automotive design. A water engine would need to incorporate safeguards against leaks, pressure surges, and potential component failures. Extensive testing and rigorous quality control procedures would be necessary to ensure reliability and prevent catastrophic failures. Predictive maintenance systems would be vital for early detection of potential issues and to optimize performance.

Components and Placement

| Component | Description | Placement in Toyota Vehicle |

|---|---|---|

| Water Reservoir | Large container holding the water source | Likely in the underbody or trunk area to maintain a low center of gravity |

| Hydro-Mechanical Conversion System | Converts water energy to mechanical energy | Potential location would depend on the specific design; likely within the engine bay |

| Transmission and Drivetrain | Transfers power to the wheels | Integrated into the existing drivetrain system |

| Control System | Manages water flow and engine operation | Within the vehicle’s electrical system |

Water Engine Car: Future Trends

The potential for water-based engine technology to revolutionize the automotive industry is significant. While still in its nascent stages, advancements in this field promise substantial environmental benefits and potentially lower operational costs compared to traditional combustion engines. This section explores potential future developments, partnerships, timelines, regulatory hurdles, and market demand for water-engine cars.

Potential Future Developments in Water Engine Technology

Ongoing research and development efforts focus on optimizing the efficiency and performance of water-based engines. This includes refining the conversion process of water’s inherent energy into mechanical power. Further advancements in materials science could lead to more durable and lightweight components for water engines, increasing overall vehicle performance and reducing manufacturing costs. Improvements in the design of the water-engine systems themselves, including cooling and lubrication systems, are crucial for ensuring long-term reliability and scalability.

Potential Partnerships Between Toyota and Other Companies

Toyota, known for its pioneering work in automotive technology, could leverage collaborations with specialized companies in areas such as materials science, energy storage, and advanced manufacturing. Partnerships with research institutions and universities could accelerate the development of innovative water-engine components and systems. Strategic alliances with battery technology companies could potentially integrate water-engine technology with hybrid or electric systems for enhanced performance and efficiency. For example, a partnership with a company specializing in hydrogen production could create a sustainable fuel cycle.

Timeline for Potential Widespread Adoption of Water Engine Cars

Predicting the precise timeline for widespread adoption of water engine cars is challenging. Several factors influence this timeline, including the pace of technological advancement, regulatory approvals, and the availability of supporting infrastructure. Early adoption is likely to be concentrated in niche markets or as demonstration vehicles, with broader market penetration anticipated within several decades. This timeline is contingent upon the successful resolution of technical hurdles and the establishment of a robust supply chain for water engine components.

Potential Regulatory Hurdles for Water Engine Vehicles

Regulatory bodies globally will need to assess the safety, environmental impact, and performance of water engine vehicles. These assessments will focus on factors such as emissions, noise levels, and potential impacts on existing infrastructure. The development of specific safety standards and regulations will be crucial for ensuring consumer confidence and the responsible integration of water engine technology into the transportation system.

Future Market Demand for Water Engine Cars

The future market demand for water engine cars depends on several factors, including consumer acceptance, the cost of ownership, and the perceived environmental benefits. As awareness of climate change and environmental sustainability grows, consumers may increasingly prioritize vehicles with reduced carbon footprints. Government incentives and regulations could also play a significant role in shaping market demand. Factors like the cost of manufacturing, maintenance, and the overall performance of the water engine cars will influence consumer acceptance.