Overview of 3D Car Models

3D car models have revolutionized the automotive industry, enabling designers, engineers, and marketers to visualize, manipulate, and simulate vehicles with unprecedented precision. From early rudimentary computer graphics to highly detailed digital renderings, the evolution of 3D car modeling has been a testament to advancements in computer technology and software. This transformation has significantly impacted various stages of the automotive lifecycle, from conceptualization to production.

The versatility of 3D car models extends far beyond the design studio. Their applications span a wide range of uses, offering detailed insights into vehicle performance, aesthetics, and even consumer appeal. This multifaceted approach allows for efficient testing, streamlined design iterations, and cost-effective marketing strategies. The seamless integration of 3D models into the modern automotive workflow showcases their crucial role in optimizing the entire process.

Evolution of 3D Car Modeling

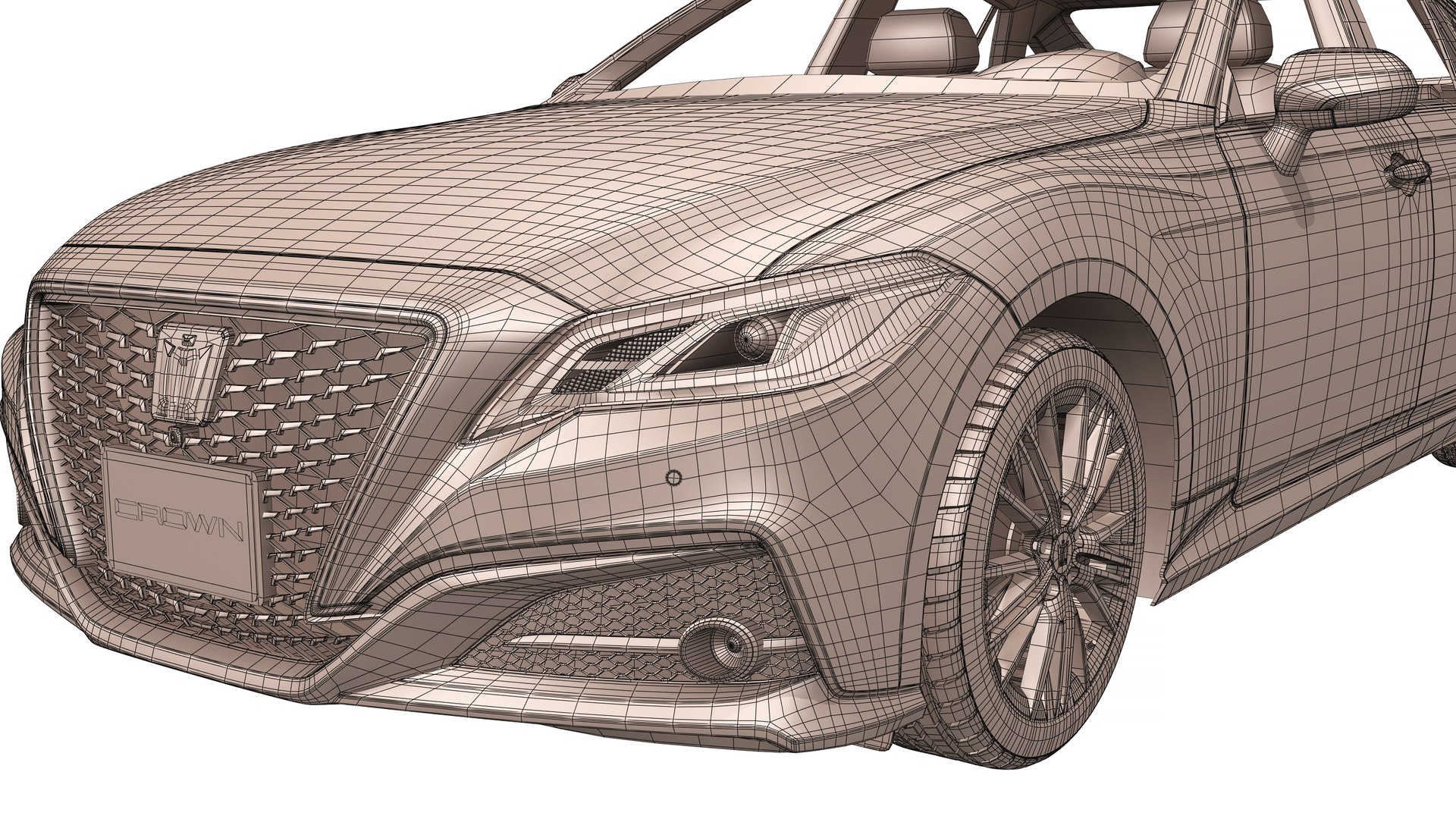

3D car modeling has evolved significantly from simple wireframes to highly realistic digital renderings. Early iterations relied on basic computer-generated imagery (CGI), which lacked the level of detail and realism seen in contemporary models. These early methods were primarily used for basic visualization and understanding of form, but lacked the precision required for complex design. Subsequent advancements in computer hardware and software enabled the creation of more complex models with accurate surface representations and detailed features. Modern 3D car modeling leverages sophisticated techniques and software to produce photorealistic renderings, paving the way for more accurate simulations and interactive experiences.

Uses of 3D Car Models

3D car models find widespread application across the automotive industry. In the design phase, these models allow designers to explore different aesthetics, configurations, and features. The ability to manipulate and modify models digitally streamlines the design process, enabling faster iterations and more efficient problem-solving. In the marketing sphere, high-quality 3D renderings are used to create captivating visuals for brochures, advertisements, and websites. Furthermore, 3D models play a critical role in simulating vehicle performance, including aerodynamic testing, crash simulations, and structural analysis. These simulations are crucial for identifying potential issues and optimizing design before physical prototypes are built.

Technical Aspects of 3D Car Modeling

Creating high-quality 3D car models involves a complex interplay of software, techniques, and artistic skills. Specialized 3D modeling software, such as Autodesk Maya, Blender, and 3ds Max, are commonly used to create, manipulate, and texture 3D models. These software tools provide a wide range of capabilities for sculpting, modeling, texturing, and rendering the final product. The process often involves meticulous detailing of every component, from the engine bay to the exterior body panels, ensuring accuracy and realism. Advanced techniques, like NURBS (Non-Uniform Rational B-Spline) modeling, are often employed to achieve smooth, curved surfaces and complex geometries.

Comparison of 3D Modeling Software

| Software | Features | Pros | Cons |

|---|---|---|---|

| Autodesk Maya | Advanced modeling, animation, and rendering capabilities; strong industry standard; extensive support community. | High level of customization, versatile features for complex tasks, robust ecosystem. | Steep learning curve; potentially expensive licensing fees; can be overwhelming for beginners. |

| Blender | Free and open-source software; extensive range of modeling tools; versatile features for both beginners and professionals. | Cost-effective; highly customizable; extensive online resources and tutorials. | Learning curve can be significant; less industry-specific features than dedicated professional software; may require more user-specific setup. |

| 3ds Max | Strong focus on 3D modeling, animation, and rendering; often used in architectural visualization; widely used in the entertainment industry. | Wide range of features for complex projects; highly effective for production-ready visuals; industry standard for many tasks. | Can be expensive; learning curve may be steep for some users; often used for specific tasks in the industry. |

Toyota 3D Car Models

Toyota utilizes 3D modeling extensively throughout its design and manufacturing processes, from initial concept sketches to final production. This digital approach offers significant advantages, allowing for iterative design modifications, precise engineering calculations, and enhanced communication among teams. The use of virtual prototypes significantly reduces the need for physical iterations, accelerating the development cycle and optimizing resource allocation.

Toyota’s commitment to 3D modeling extends beyond the design phase. The models are crucial for manufacturing processes, facilitating the creation of detailed assembly instructions and allowing for simulations of various operational scenarios. This integrated approach ensures efficiency and quality control throughout the entire production chain.

Toyota’s 3D Modeling in Design

Toyota employs advanced 3D modeling software to develop intricate designs, enabling the creation of detailed visualizations of potential vehicle configurations. These digital representations are used to explore various design parameters, allowing engineers to evaluate aesthetic appeal, functionality, and overall performance before committing to physical prototypes. The process of virtual testing significantly reduces the need for extensive physical iterations, saving time and resources.

Examples of Modeled Toyota Vehicles

Toyota has utilized 3D modeling for a vast array of vehicles, from compact cars to SUVs and trucks. The Camry, for example, features a sleek, aerodynamic design that is meticulously refined through 3D modeling. The innovative features of the 2023 Camry, such as its interior design and advanced infotainment system, are carefully planned and refined using 3D models. Similarly, the RAV4, known for its versatility and off-road capabilities, underwent extensive 3D modeling to optimize its structural integrity and performance. The 3D models allow for the accurate representation of complex geometries, such as the suspension systems and intricate body panels. This enables the creation of precise specifications for manufacturing.

Comparison to Other Manufacturers

Toyota’s approach to 3D modeling is comparable to that of leading automotive manufacturers like Volkswagen, Ford, and BMW. These companies all utilize 3D modeling extensively in their design and manufacturing processes. However, specific approaches may differ in terms of software choices, modeling techniques, and the level of integration with other engineering disciplines. Some manufacturers may emphasize specific aspects of the process, such as aerodynamic optimization or interior design.

Detailed Description of the Toyota GR86

The Toyota GR86, a sports coupe, is a prime example of how 3D modeling enhances vehicle design. The GR86’s 3D model meticulously depicts its low-slung profile, sculpted body panels, and distinctive aerodynamic features. The 3D model allows for the precise representation of the car’s geometry, including the intricate contours of the hood, fenders, and trunk lid. The use of 3D modeling facilitates the accurate simulation of airflow around the vehicle, allowing engineers to optimize aerodynamics and reduce drag. The model also details the precise placement of components, such as the engine compartment, suspension, and braking system. These detailed visualizations are crucial for efficient manufacturing and quality control.

3D Car Models and Design

Accurate 3D models are crucial in the automotive design process, enabling engineers and designers to visualize and manipulate vehicle components before physical prototypes are created. This iterative approach saves time and resources, allowing for adjustments and refinements based on real-time feedback. From initial conceptualization to final production, 3D modeling plays a pivotal role in optimizing the design and ensuring the vehicle meets its intended specifications.

3D modeling facilitates a seamless transition from initial sketches to a detailed, tangible representation of the vehicle. This allows for comprehensive analysis of form, function, and aesthetics. Early detection of potential design flaws and the optimization of ergonomics and aerodynamics are possible through 3D modeling, leading to more efficient and innovative designs. The process of creating these models is intricate and requires expertise, precision, and adherence to industry standards.

Accuracy in 3D Car Models

The accuracy of 3D car models is paramount for design purposes. Precise measurements and detailed representations of components are essential to ensure the final product aligns with the intended specifications. Imperfect models can lead to costly errors and delays in the manufacturing process. In addition, accurate 3D models allow for detailed simulations, assessing aspects like aerodynamics and structural integrity. This early identification of potential problems reduces the likelihood of costly rework or design revisions later in the process.

Impact of 3D Modeling on the Design Process

3D modeling significantly impacts the automotive design process, streamlining the workflow from initial concept to final production. From conceptual sketches, 3D models translate the initial design intent into a tangible representation. This allows designers to explore different design variations, test various configurations, and refine the model iteratively. The ability to manipulate and rotate the 3D model provides invaluable insights into the vehicle’s form, function, and aesthetics. Further, 3D models enable detailed analysis of the car’s ergonomics and interior space, improving the overall user experience.

Steps in Creating a Comprehensive 3D Car Model

Creating a comprehensive 3D car model involves a multi-step process that requires specialized software and technical expertise. First, designers establish the basic shape and form of the vehicle using CAD software. Subsequently, the model is refined by adding intricate details, including the precise dimensions of each component, like the engine compartment, body panels, and interior elements. Advanced modeling techniques, such as surface modeling and solid modeling, ensure the accuracy and realism of the final model. Furthermore, the model is meticulously detailed, including textures, materials, and lighting effects. Finally, the model is thoroughly tested and validated to ensure its accuracy and compatibility with engineering specifications.

Stages of Car Design Using 3D Modeling

| Stage | Description | Key Activities | Output |

|---|---|---|---|

| Concept Design | Initial design exploration, focusing on the overall form and functionality of the vehicle. | Sketching, brainstorming, initial 3D modeling of key features, and renderings to visualize potential designs. | Conceptual model, showcasing the core design concepts and features. |

| Detailed Design | Refinement of the concept design, incorporating precise specifications and details. | Detailed 3D modeling, rendering, and simulations of the vehicle’s performance and functionality. Extensive analysis of aerodynamics, ergonomics, and structural integrity. | Detailed model, ready for engineering and manufacturing processes. |

| Production Design | Transitioning the detailed design into a format suitable for manufacturing. | Creation of manufacturing drawings, specifications, and templates. | Production-ready model with all required data for manufacturing. |

3D Car Models and Marketing

3D car models are revolutionizing automotive marketing, offering a powerful tool to engage potential customers and showcase vehicles in a dynamic, interactive way. They transcend traditional static imagery, enabling a deeper understanding and appreciation of a car’s design, features, and overall aesthetic. This enhanced engagement is crucial in a competitive market where differentiation is key.

3D models are not just static representations; they are dynamic tools. Their use in marketing campaigns extends beyond simple visualization, allowing for interactive experiences, personalized configurations, and immersive virtual test drives. This innovative approach empowers customers to explore vehicles in a more intuitive and engaging manner, ultimately leading to higher conversion rates.

Applications in Automotive Advertising

3D models offer a compelling alternative to traditional advertising methods. They create a more immersive experience for potential customers, allowing them to interact with the vehicle in a way that static images cannot replicate. This is particularly valuable in showcasing complex designs, intricate details, and innovative features that might be difficult to convey through two-dimensional media.

Benefits of Using 3D Models in Promotional Materials

The benefits of incorporating 3D models in promotional materials are multifaceted and significant. They foster a sense of excitement and anticipation around a new product launch. Potential buyers are more likely to engage with a dynamic, interactive model than a static image. This leads to increased brand recall and a stronger connection with the product.

- Enhanced Engagement: 3D models provide a dynamic, interactive platform, allowing potential buyers to explore the car from multiple angles, visualize different configurations, and even virtually test drive it. This immersive experience fosters a deeper connection with the vehicle, surpassing the limitations of static images or videos.

- Improved Brand Recall: The innovative approach of 3D models creates a lasting impression, setting the brand apart from competitors. This memorable experience increases the likelihood of consumers remembering and associating positive attributes with the brand.

- Increased Conversion Rates: By offering a more comprehensive and engaging experience, 3D models can lead to higher conversion rates. The ability to interact with a model, visualize options, and virtually experience the vehicle can significantly impact the purchasing decision.

- Cost-Effectiveness: While the initial investment in 3D modeling software and talent may seem significant, the long-term return on investment is often substantial. The increased engagement and conversion rates can offset these costs and contribute to a more effective marketing strategy.

Role of 3D Visualization in Attracting Potential Customers

3D visualizations play a pivotal role in attracting potential customers. They allow potential buyers to experience the vehicle in a way that transcends traditional marketing methods. This immersive experience fosters a sense of connection and excitement, making the vehicle more appealing and desirable.

A Hypothetical Promotional Campaign

To demonstrate the effectiveness of 3D models, consider a promotional campaign for a new Toyota SUV.

- Phase 1: Teaser Campaign (Online): Release captivating 3D renderings of the SUV’s exterior and interior design elements on social media platforms, automotive websites, and targeted advertising campaigns. Create short, engaging videos showcasing the car’s dynamic features. Offer virtual tours or interactive configurators for users to personalize the vehicle.

- Phase 2: Interactive Experience (Showrooms): Utilize 3D models in physical showrooms. Allow customers to explore the car in detail using interactive displays. Offer virtual test drives or personalized configuration options using tablets or computers. Provide high-quality 3D printed models for physical interaction and hands-on exploration.

- Phase 3: Extended Engagement (After-Sales): Create 3D models showcasing the car’s customization options and accessories. Engage customers on social media by showcasing user-created 3D model configurations. Offer personalized 3D renders of customers’ customized vehicles as a thank-you or promotional incentive.

3D Car Models and Simulation

3D car models are crucial tools in the automotive industry, extending beyond design visualization to encompass sophisticated simulations. These simulations allow engineers to test and refine vehicle performance under various conditions, leading to more efficient, safer, and ultimately, better-performing vehicles. This process is integral to the development and improvement of modern automobiles.

Accurate simulations are possible due to the detailed representation of vehicle components and their interactions within the 3D model. This enables engineers to evaluate various aspects of vehicle performance, from aerodynamics to crashworthiness.

Applications of Simulation in Testing Vehicle Performance

Simulation plays a pivotal role in the testing and refinement of vehicle performance characteristics. By replicating real-world driving conditions within a virtual environment, engineers can evaluate vehicle responses under diverse circumstances. This approach offers numerous advantages over traditional physical testing, particularly in terms of cost and time efficiency.

- Aerodynamic Testing: 3D models allow for the evaluation of airflow patterns around the vehicle, enabling engineers to identify areas of turbulence and optimize the vehicle’s shape for reduced drag. This process can be iterated through the simulation, reducing the number of physical prototypes required.

- Crashworthiness Testing: Sophisticated crash simulations can assess the safety of a vehicle’s structure and occupants during collisions. This crucial aspect of automotive engineering ensures the vehicle conforms to safety standards and protects passengers in a variety of potential accident scenarios. By using virtual crash tests, engineers can examine the impact forces and structural integrity without the need for expensive and potentially hazardous physical experiments.

- Fuel Efficiency Analysis: Simulations allow for the examination of engine performance and fuel consumption under various driving conditions. This data aids in the optimization of engine design and vehicle parameters to enhance fuel efficiency and reduce emissions. This process can significantly impact the overall environmental footprint of the vehicle.

- Ride Comfort and Handling: Engineers can analyze suspension performance, steering response, and handling characteristics by simulating various road surfaces and driving conditions. This iterative process ensures a comfortable and responsive driving experience. Adjustments can be made to the suspension, steering, and other elements without the need for extensive physical testing, reducing development time.

Importance of Accurate 3D Models in Simulations

The accuracy of the 3D model directly impacts the reliability and validity of the simulation results. Inaccurate models can lead to misleading conclusions, hindering the design process and potentially impacting the final product. The detailed representation of components and their interactions is critical for producing realistic simulations.

- Precision in Representation: Accurate modeling of components, including materials, geometry, and physical properties, is essential for creating realistic simulations. Detailed 3D models of each component allow engineers to account for the unique characteristics of different materials and their interaction under various conditions.

- Real-world Replication: Simulations aim to replicate real-world conditions as closely as possible. Accurate 3D models help in achieving this goal, allowing engineers to evaluate the vehicle’s response to diverse scenarios.

- Data Reliability: The validity of simulation results hinges on the accuracy of the 3D model. Inaccurate models lead to unreliable data, potentially delaying development or compromising the final product’s quality.

Different Types of Simulations Performed on 3D Car Models

Various simulation types are employed to evaluate different aspects of a vehicle’s performance.

- Finite Element Analysis (FEA): FEA is used to analyze stress and strain on components under various loads. This is particularly important for assessing the structural integrity of the vehicle and its components, such as the frame and chassis, under extreme conditions.

- Computational Fluid Dynamics (CFD): CFD simulations model the flow of fluids around the vehicle, enabling engineers to optimize aerodynamics and reduce drag. This detailed understanding is vital in enhancing fuel efficiency and overall performance.

- Multibody Dynamics Simulations: These simulations analyze the dynamic interactions between different components of the vehicle, like the engine, transmission, and suspension. This allows for the evaluation of vehicle handling, stability, and overall performance under varying driving conditions.

3D Car Models and Future Trends

The automotive industry is undergoing a digital transformation, with 3D modeling playing a crucial role in accelerating design, development, and production. This evolution is driven by the increasing sophistication of 3D modeling software, the integration of advanced technologies, and the growing demand for personalized and efficient vehicle manufacturing. The future of automotive design is inextricably linked to the continued advancement of 3D modeling techniques.

The future of 3D car modeling will be defined by its integration with emerging technologies, leading to more efficient design processes, enhanced realism, and the creation of truly personalized vehicles. Advancements in 3D modeling are reshaping the automotive industry, from the initial design concept to the final production of the car. The incorporation of AI and machine learning is particularly promising in automating tasks, improving accuracy, and generating innovative design solutions.

Emerging Technologies in 3D Modeling

Advancements in 3D modeling technologies are constantly pushing the boundaries of what’s possible in automotive design. These advancements are enabling more complex and detailed models, creating more realistic simulations, and facilitating faster iterations in the design process. Examples include:

- High-Resolution Modeling: The ability to create models with unprecedented detail and accuracy is enabling more realistic simulations and a better understanding of vehicle performance. This translates to better aerodynamics, improved fuel efficiency, and enhanced structural integrity. For instance, simulations using extremely detailed 3D models are already used to test the aerodynamic performance of vehicles in wind tunnels, providing invaluable data for design optimization.

- Interactive 3D Design Environments: The development of interactive platforms allows designers to explore and manipulate models in a more intuitive and collaborative manner. This leads to faster iteration cycles, enabling designers to rapidly explore different design options and refine them in real-time. Collaborative environments also allow for seamless communication between design teams, engineers, and stakeholders.

- Advanced Rendering Techniques: Improvements in rendering techniques allow for the creation of highly realistic images and animations of the vehicles. This allows for a more comprehensive understanding of the vehicle’s appearance and design from various perspectives. Advanced rendering tools allow for the creation of highly realistic visualizations of vehicle interiors, exteriors, and functional components.

Impact of AI and Machine Learning

AI and machine learning are poised to revolutionize 3D car modeling, automating tasks, improving accuracy, and driving innovation. The use of AI in design is already impacting several industries, including the automotive sector.

- Automated Design Generation: AI algorithms can analyze existing designs, identify trends, and generate new design concepts. This automation can free up designers to focus on more creative aspects of the design process. For example, AI can be used to generate variations of a vehicle design, providing designers with a broader range of options to explore and potentially accelerate the development process.

- Predictive Modeling: AI can predict the performance and behavior of a vehicle under various conditions, providing valuable insights into design improvements. This process could include predicting the aerodynamic performance of a vehicle, or the structural integrity under different load conditions, allowing engineers to refine their designs before physical prototypes are created.

- Personalized Design: Machine learning can analyze customer preferences and generate customized designs. This personalization will be a key driver in the future of automotive design, allowing for a more tailored experience for each individual. This can range from customizing interior features to tailoring the vehicle’s exterior design.

Future of 3D Car Modeling and Design

The future of 3D car modeling in the automotive industry promises significant advancements. These advancements will lead to a more efficient and innovative design process, enabling the development of more personalized and sustainable vehicles.

- Virtual Prototyping and Simulation: The increasing use of virtual prototyping and simulation tools will allow for comprehensive testing and evaluation of vehicles before physical prototypes are built. This will significantly reduce development time and costs, and enable more comprehensive testing, including crashworthiness, performance, and aerodynamic characteristics.

- Sustainable Design: 3D modeling will play a critical role in designing more sustainable vehicles, optimizing vehicle aerodynamics for fuel efficiency, and creating lightweight materials. This will allow for the creation of vehicles with a reduced environmental impact.

- Increased Efficiency: The integration of AI and automation will enhance the efficiency of the entire design process. This will lead to faster turnaround times, reduced costs, and more efficient use of resources.