Toyota 3D Car Models

Toyota, a global automotive giant, leverages 3D modeling extensively for design visualization, prototyping, and manufacturing. The use of 3D models allows for iterative design improvements and efficient communication between engineers and designers. This detailed exploration delves into the diverse world of Toyota 3D car models, encompassing their design features, evolution, creation processes, and associated file formats.

Design Features and Aesthetics

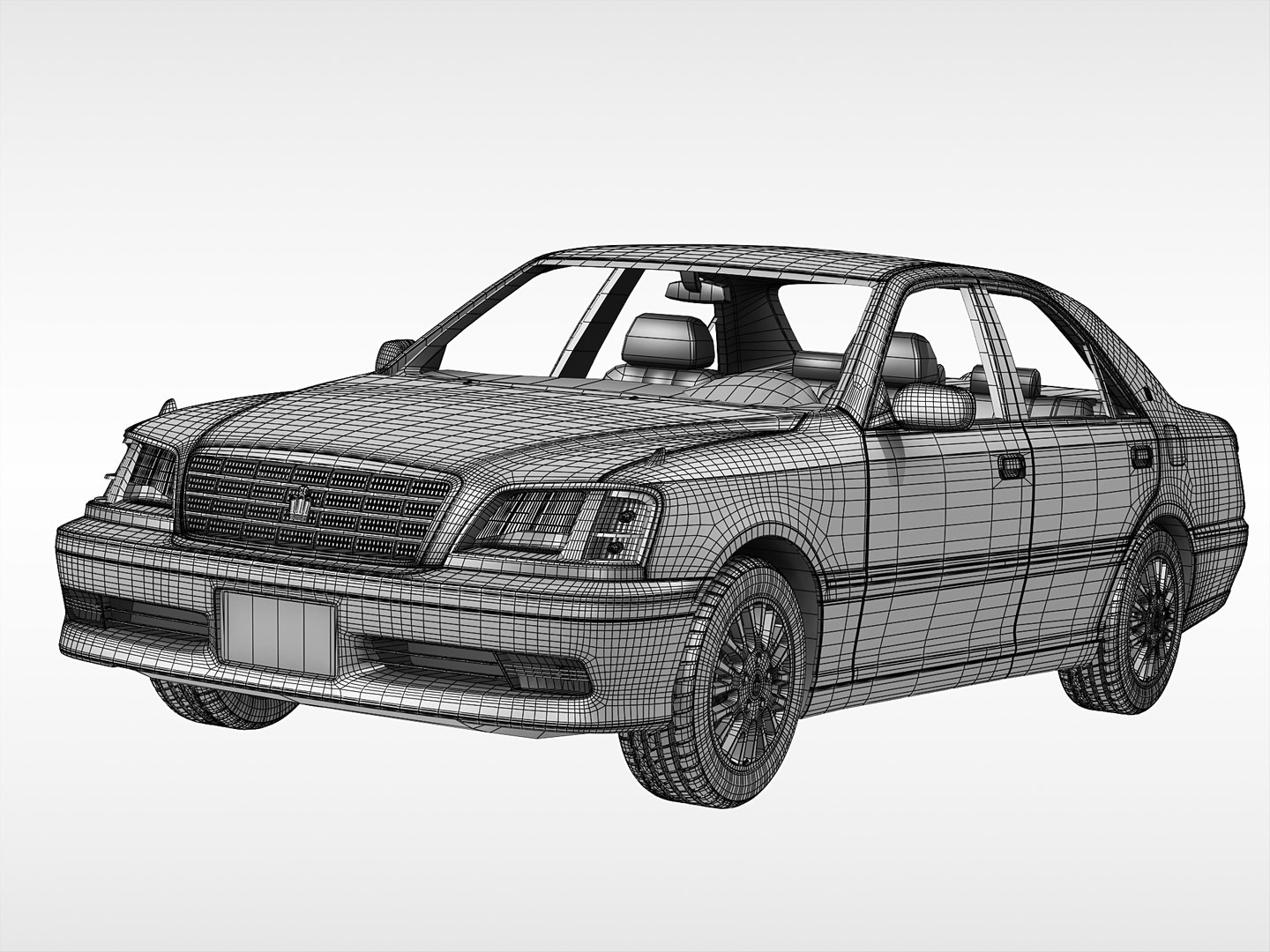

Toyota 3D car models showcase a wide array of design aesthetics, ranging from the sleek and futuristic to the robust and practical. Early models often emphasized functional design, while contemporary models incorporate aerodynamic elements and intricate details. The design language reflects Toyota’s commitment to both efficiency and elegance. A comparison reveals an evolution in design features, progressing from simpler shapes to more complex curves and surface treatments. This evolution reflects advancements in design philosophy, technological capabilities, and consumer preferences.

Evolution of Design Aesthetics

Toyota’s 3D car models demonstrate a clear evolution in design aesthetics. Early models often emphasized a more boxy or rounded aesthetic, reflecting the design trends of their time. Over the decades, Toyota’s designs have incorporated more streamlined forms and sophisticated detailing, aligning with the demands of contemporary automotive aesthetics. This evolution can be traced through various model series and generations. For example, the shift from the rounded shapes of the 1980s to the more aerodynamic profiles of modern models is a clear demonstration of this design progression.

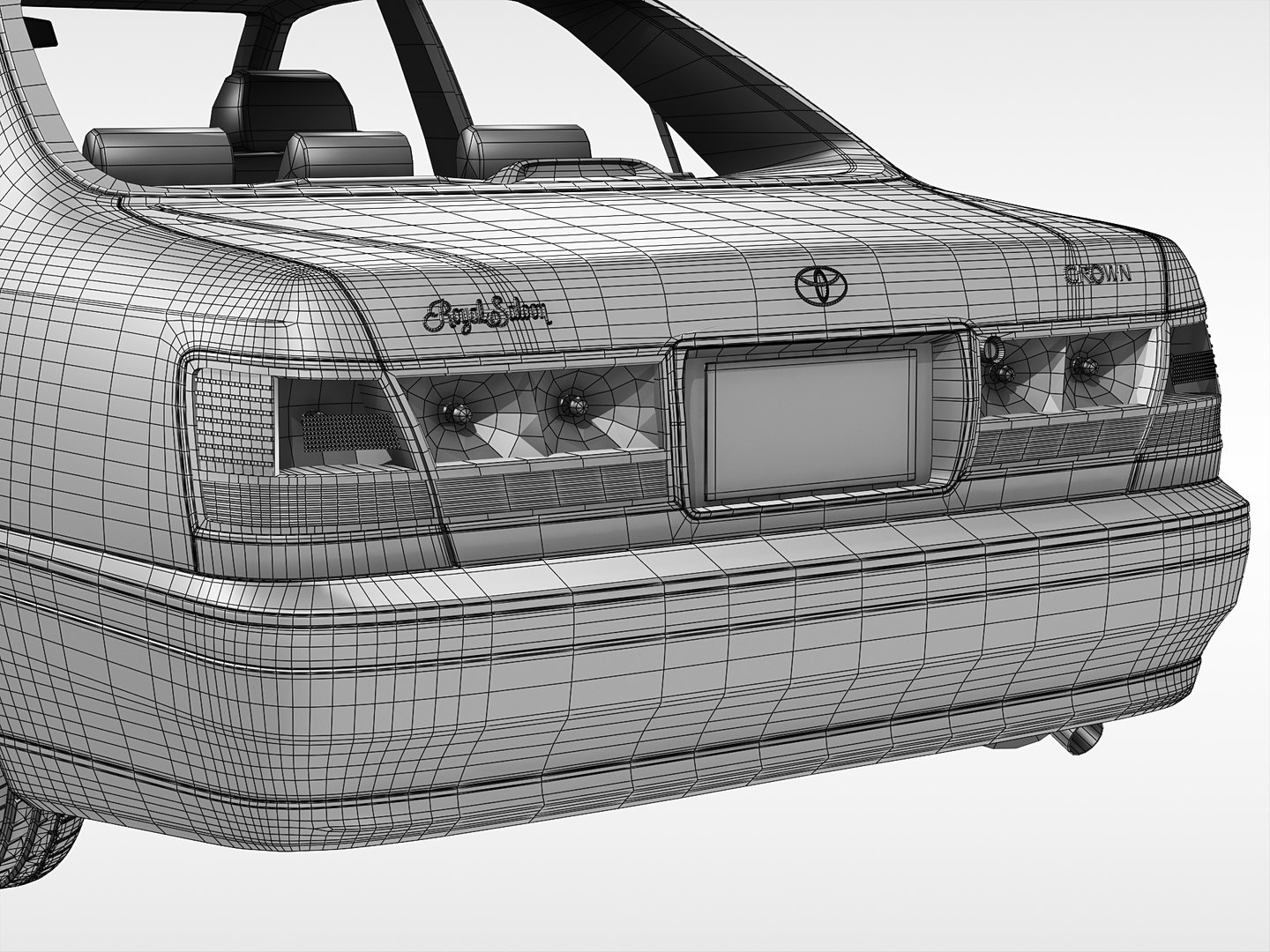

3D Modeling Software and Techniques

Several 3D modeling software packages are likely utilized by Toyota for creating their car models. These include industry-standard programs like Autodesk Maya, 3ds Max, and Rhinoceros. Advanced techniques such as NURBS (Non-Uniform Rational B-Spline) modeling, and digital sculpting, are employed for creating complex shapes and details. The choice of software and techniques depends on the specific requirements of each project.

File Formats for 3D Models

Various file formats are used to represent Toyota 3D car models. Common choices include STL (Stereolithography), OBJ (Wavefront OBJ), and 3MF (3D Manufacturing Format). STL files are commonly used for 3D printing, while OBJ files are often utilized for rendering and animation. 3MF files are designed for 3D printing and manufacturing processes. Each format has specific characteristics and capabilities that influence its suitability for various applications.

Table of Toyota 3D Car Models

| Car Model | Year | Key Design Features | File Formats |

|---|---|---|---|

| Camry | 2023 | Sleek profile, aerodynamic design, enhanced interior technology. | STL, OBJ, 3MF |

| RAV4 | 2022 | Robust SUV design, practical interior space, advanced safety features. | STL, OBJ, 3MF |

| Corolla | 2021 | Compact sedan, fuel-efficient design, enhanced interior comfort. | STL, OBJ, 3MF |

| Prius | 2020 | Hybrid design, futuristic styling, eco-friendly features. | STL, OBJ, 3MF |

3D Car Visualization of Toyota Models

Toyota utilizes 3D car models extensively in various stages of product development, from initial design to marketing and customer engagement. These digital representations offer significant advantages over traditional 2D methods, allowing for more accurate and comprehensive visualization of car features and performance. The use of interactive 3D models enables potential customers to explore and understand the design elements of a vehicle in a way that was previously not possible.

3D car models are an integral part of the modern automotive industry. From conceptualization to final production, they facilitate precise analysis, detailed design modifications, and efficient communication across diverse teams. They allow for thorough evaluation of design choices and potential issues, reducing costly revisions later in the process. This translates into quicker turnaround times and improved overall efficiency.

Advantages of 3D Car Models in Visualizing Toyota Car Features

3D models provide a dynamic and interactive way for customers to experience a vehicle’s features. Potential buyers can virtually “walk around” a car, inspect its details, and assess its ergonomics in a way that static images or 2D renderings cannot replicate. This immersive experience fosters a stronger connection with the product and significantly enhances the understanding of the car’s design elements.

3D Models in Car Design and Engineering

The use of 3D models is crucial throughout the design and engineering process. Early-stage conceptualization benefits from rapid prototyping and iterative design modifications enabled by 3D modeling software. Engineers can virtually test different designs, simulate performance scenarios, and identify potential issues, all before physical prototypes are built. This approach significantly reduces development time and costs by addressing potential problems early in the design phase. Detailed 3D models facilitate precise measurements, allowing for accurate production planning and ensuring a smooth transition from design to manufacturing.

3D Models in Marketing and Advertising

3D models are powerful tools in marketing materials and advertising campaigns. Interactive 3D visualizations of Toyota cars can be integrated into websites, brochures, and promotional videos, creating a compelling and immersive experience for potential customers. These models can showcase intricate details, highlight key features, and convey the car’s aesthetic appeal effectively. 3D animations demonstrating features like opening doors or adjusting seats are especially engaging and informative.

Toyota 3D Models in Use

| Application | Purpose | Advantages | Examples |

|---|---|---|---|

| Pre-production Design | Testing and refining designs, identifying potential issues, and simulating performance | Reduces design iterations, minimizes costs, and accelerates development | Toyota’s use of 3D models to optimize the aerodynamics of a new sports car. |

| Customer Engagement | Creating interactive experiences that showcase features and allow customers to visualize the vehicle from various angles. | Improves customer understanding, increases engagement, and fosters a stronger connection with the product. | Virtual showrooms that allow customers to explore different trim levels and options. |

| Marketing Materials | Creating compelling visuals for brochures, websites, and advertisements. | Provides dynamic and immersive experiences for potential customers. | 3D animations showcasing the car’s advanced safety features. |

Interactive 3D Experiences with Toyota Cars

Toyota leverages cutting-edge 3D technology to enhance the customer experience, moving beyond static images and showcasing vehicles in dynamic, engaging ways. This approach allows potential buyers to explore models virtually, fostering a deeper connection with the vehicles and potentially influencing purchase decisions. The interactive nature of these experiences creates a more personalized and immersive journey for consumers.

Interactive 3D experiences offer a compelling alternative to traditional methods of car visualization. By providing virtual test drives and 360-degree views, these technologies allow customers to experience the vehicle’s features and design from a variety of perspectives, enhancing their understanding and appreciation.

Virtual Test Drives

Virtual test drives are a crucial aspect of interactive 3D experiences. These simulations offer a realistic driving experience, allowing users to explore the vehicle’s handling, acceleration, and braking characteristics without physically being behind the wheel. This capability is especially beneficial for customers who are unable to visit a dealership in person or who want to get a feel for the car before visiting a showroom.

360-Degree Views

360-degree views provide a comprehensive perspective of the vehicle, enabling customers to examine the exterior and interior from all angles. This feature allows customers to thoroughly inspect the car’s design, highlighting specific details such as the dashboard layout, seating arrangements, and storage compartments. This comprehensive view aids in making informed purchasing decisions.

Other Interactive Experiences

Beyond virtual test drives and 360-degree views, Toyota might also incorporate interactive elements like dynamic interior customization options, allowing users to select different colors, materials, and configurations to visualize the vehicle’s potential. This interactive approach empowers consumers to visualize the vehicle in a personalized way.

User Interface Elements

User interface elements in interactive 3D car experiences typically include intuitive controls for navigating the virtual environment. These controls might include a virtual steering wheel, pedals, and a dashboard that mirrors the real vehicle’s layout. Clear labeling of controls and features is crucial for user engagement.

Table of Interactive 3D Experiences

| Experience Type | Features | Benefits | Platforms |

|---|---|---|---|

| Virtual Test Drive | Simulated driving experience, adjustable controls (acceleration, braking, steering), various road conditions | Realistic feel of the car’s performance without physical interaction, enabling customers to assess the vehicle’s driving dynamics from the comfort of their home. | Toyota’s website, dedicated mobile apps |

| 360-Degree View | Complete panoramic view of the exterior and interior, zoom and pan functionalities | Detailed examination of the car’s design elements, interior features, and overall aesthetic. | Toyota’s website, dedicated mobile apps, online configurator tools |

| Interior Customization | Interactive options to modify colors, materials, and configurations | Personalized visualization of the vehicle’s potential, allowing customers to see how different options affect the car’s appearance and feel. | Toyota’s website, dedicated mobile apps, online configurator tools |

3D Car Customization Options for Toyota

Toyota’s commitment to 3D modeling has opened exciting avenues for car customization. 3D visualizations empower customers to explore a vast array of aftermarket parts and accessories before committing to a purchase. This interactive approach not only enhances the customer experience but also ensures greater satisfaction with the final product.

The use of 3D modeling in car customization goes beyond mere aesthetics. It allows customers to virtually “try on” different components, ensuring a perfect fit and visual harmony. This reduces the risk of unforeseen issues and potential disappointments, ultimately leading to higher customer satisfaction.

Customization Options for Toyota Vehicles

A wide range of aftermarket parts and accessories are available for Toyota vehicles, catering to diverse preferences and needs. These include performance enhancements, aesthetic upgrades, and functional additions. The ability to visualize these modifications in a realistic 3D environment is a key advantage for potential customers.

Visualizing Customized Options

3D models of Toyota vehicles allow for the precise visualization of customized options. Customers can virtually install different bumpers, spoilers, or wheel sets to see how they integrate with the vehicle’s design. This pre-purchase visualization tool minimizes the risk of unexpected outcomes and provides a sense of ownership and satisfaction before any physical modification is made. The 3D model accurately reflects the car’s proportions and features, ensuring the customization aligns with the customer’s vision.

Impact on Customer Engagement and Satisfaction

3D customization tools significantly enhance customer engagement. The interactive nature of these tools allows for a deeper understanding of the customization options and their impact on the vehicle’s appearance. This, in turn, leads to greater customer satisfaction as they can confidently select the modifications that best meet their aesthetic and functional needs. The ability to visualize a customized car before purchasing can lead to a more informed and satisfying decision-making process.

Importance of Accurate 3D Models

Accurate 3D models are crucial for the customization process. Inaccuracies can lead to misinterpretations of the fit, proportion, and overall aesthetic of the customized vehicle. The use of precise 3D models ensures that the visual representation of the customization accurately reflects the final product. High-fidelity 3D models minimize the risk of costly errors or mismatches between the customer’s vision and the actual result.

Comparison of Customization Options

| Customization Option | Price Range (USD) | Key Features | Availability |

|---|---|---|---|

| Performance Exhaust System | $500 – $2,000 | Improved engine sound, enhanced horsepower, potential fuel efficiency gains | Widely available for most Toyota models |

| Carbon Fiber Body Kit | $1,000 – $5,000 | Enhanced aesthetic appeal, lightweight construction, improved aerodynamics | Available for various Toyota models, depending on the specific design |

| LED Headlights | $200 – $800 | Improved visibility, enhanced styling, increased safety | Commonly available for many Toyota models, with varying designs |

| Custom Wheels and Tires | $500 – $3,000+ | Enhanced visual appeal, improved handling, increased tire size options | Widely available from various aftermarket suppliers |

The table above provides a general overview of customization options, but specific pricing and features can vary significantly based on the chosen model, supplier, and specific design elements. Always verify the details with the manufacturer or supplier.

3D Car Maintenance and Repair

Toyota utilizes 3D models extensively in its training and repair processes, significantly enhancing the capabilities of its technicians. These digital representations offer a level of detail and accessibility previously unattainable with traditional methods, ultimately leading to more efficient and accurate repairs.

3D models provide a powerful tool for technicians to visualize complex car parts and mechanisms in a highly interactive manner. This interactive exploration facilitates a deeper understanding of the intricacies of vehicle design, enabling technicians to identify potential issues more readily and to perform repairs with greater confidence. The accuracy of these models ensures that the training and repair procedures align precisely with the physical vehicle components.

Training Toyota Technicians

Detailed 3D models of various car parts are invaluable for Toyota technicians undergoing training. These models are not simply static images but dynamic, interactive representations allowing technicians to explore the internal workings of a car part without physically disassembling it. This interactive approach fosters a more comprehensive understanding of the intricate relationships between different components. The virtual environment allows technicians to practice maintenance and repair procedures repeatedly, minimizing the risk of errors in real-world scenarios.

Benefits of Using 3D Models in Car Repair

The benefits of using 3D models in car repair extend beyond the training process. These models offer unparalleled accuracy in visualizing complex geometries, ensuring technicians have a precise understanding of the components they are working with. Furthermore, the accessibility of these digital resources allows technicians to access information and simulations anytime, anywhere, enhancing their knowledge and proficiency.

Understanding Complex Car Parts and Mechanisms

3D models provide a crucial tool for understanding complex car parts and mechanisms. By offering detailed visualizations, these models allow technicians to see the intricate relationships between components, identifying potential points of failure and the precise steps required for repair. This detailed view helps prevent costly errors and promotes efficient repair procedures.

Integration into Maintenance and Repair Manuals/Software

Toyota incorporates 3D models into its maintenance and repair manuals and software platforms. This integration allows technicians to navigate the vehicle’s architecture in a more intuitive way. Interactive simulations and exploded views within these platforms enable a clearer comprehension of component interactions and disassembly/assembly sequences.

Examples of 3D Models in Training and Repair

| Car Part | Corresponding 3D Model | Use Case |

|---|---|---|

| Engine Cylinder Head | Detailed 3D model showcasing valve arrangement, gasket placement, and coolant passages | Training on valve adjustments, gasket replacements, and coolant system diagnosis |

| Transmission Housing | 3D model of the transmission housing showing gear alignment, bearing placements, and oil channels | Troubleshooting transmission issues, identifying wear patterns, and understanding gear engagement mechanisms |

| Brake Caliper | 3D model of the brake caliper with detailed depictions of the piston, pad, and mounting points | Training on brake pad replacements, caliper adjustments, and understanding brake system function |

| Suspension Arm | 3D model of the suspension arm highlighting ball joints, bushings, and mounting points | Troubleshooting suspension issues, understanding component wear, and identifying necessary replacements |

Future Trends in 3D Toyota Cars

Toyota, like other automotive giants, is leveraging 3D modeling to optimize its design and manufacturing processes. This trend is accelerating, driven by advancements in 3D printing, simulation technologies, and customer-centric design approaches. The integration of these technologies promises to significantly reshape the automotive landscape, offering innovative solutions for design, production, and customization.

Potential Applications of Emerging Technologies

The integration of emerging technologies is transforming the way automotive companies approach design and manufacturing. 3D modeling facilitates rapid prototyping, enabling engineers to test various design iterations quickly and efficiently. This iterative process leads to enhanced designs, optimized performance, and ultimately, improved customer satisfaction. Virtual simulations, a crucial part of the process, allow for rigorous testing of vehicle performance and safety characteristics, significantly reducing the need for physical prototypes and expensive on-road testing.

Role of 3D Printing in Custom Parts

3D printing is revolutionizing the production of custom parts. This technology enables the creation of complex geometries and intricate designs, something not readily achievable with traditional manufacturing methods. Toyota can use 3D printing to produce personalized parts tailored to specific customer needs, from unique interior trims to customized suspension components. This approach not only caters to individual preferences but also allows for the rapid prototyping and testing of these bespoke components, streamlining the development process. The potential for on-demand production of customized parts, especially for niche markets, is immense.

Enhanced Design and Testing of Future Models

3D models play a crucial role in the design and testing of future Toyota models. Using virtual environments, engineers can meticulously test vehicle performance under various conditions, including extreme weather scenarios and challenging terrains. This virtual testing phase reduces the reliance on physical prototypes, lowering costs and significantly shortening development cycles. 3D models facilitate intricate analysis of aerodynamics, structural integrity, and overall vehicle performance.

Table: Future Trends in 3D Toyota Car Design

| Technology | Potential Application | Predicted Impact | Example Visualizations |

|---|---|---|---|

| Advanced Simulation Software | Virtual testing of vehicle performance in various conditions (e.g., extreme weather, off-road). | Reduced reliance on physical prototypes, faster development cycles, and more efficient design iterations. | A dynamic simulation of a Toyota SUV navigating a snowy mountain pass, highlighting the vehicle’s handling and stability. |

| High-Resolution 3D Scanning | Capturing real-world data for accurate 3D models of existing vehicles and parts. | Improved accuracy and precision in 3D modeling, leading to more detailed and realistic designs. | A highly detailed 3D scan of a Toyota Camry, showcasing the intricate details of the bodywork and interior components. |

| Additive Manufacturing (3D Printing) | Production of custom parts, personalized interior components, and specialized tooling. | Increased customization options, reduced lead times for specific parts, and potential for on-demand manufacturing. | A 3D-printed dashboard component with a unique design and integrated sensors, showcasing its customization potential. |

| Artificial Intelligence (AI) | Automated design optimization, material selection, and predictive maintenance based on vehicle usage patterns. | Improved efficiency in the design process, optimized vehicle performance, and proactive maintenance strategies. | An AI-powered visualization of a Toyota car model, dynamically adjusting its design features based on real-time data and customer preferences. |